- 0086-571-85302990

- sales@greenskybio.com

Eucommia ulmoides Extract: Uses, Advantages and Manufacturing Processes

2024-11-11

1. Introduction

Eucommia ulmoides, also known as the "Chinese rubber tree," has been used in traditional Chinese medicine for centuries. The extract from Eucommia ulmoides is a valuable natural product that has attracted increasing attention in recent years. This article will explore its applications, advantages, and manufacturing processes in detail.

2. Applications of Eucommia Ulmoides Extract

2.1 Medical Applications

Health Care: Eucommia Ulmoides Extract contains a variety of active ingredients that are beneficial for human health. One of its important functions is to improve blood circulation. By promoting the smooth flow of blood in the body, it can help prevent various cardiovascular diseases. For example, it may help reduce blood viscosity and prevent the formation of blood clots.

Another significant aspect is its role in enhancing the immune system. A strong immune system is crucial for the body to defend against diseases. The active components in the extract can stimulate the immune cells, such as lymphocytes and macrophages, to function more effectively, thereby increasing the body's resistance to infections and diseases.

2.2 Cosmetics Applications

Antioxidant Properties: In the cosmetics industry, Eucommia Ulmoides Extract has shown great potential. It has antioxidant properties, which means it can combat free radicals in the body. Free radicals are unstable molecules that can cause damage to cells, leading to premature aging of the skin. By neutralizing these free radicals, the extract can help keep the skin young and healthy.

It can also be used in various skin care products, such as creams, lotions, and serums. When incorporated into these products, it can improve the skin's texture, increase moisture retention, and reduce the appearance of wrinkles and fine lines.

3. Advantages of Eucommia ulmoides Extract

3.1 Natural and Green

One of the most prominent advantages of Eucommia ulmoides extract is that it is a natural and green material. In an era when people are increasingly concerned about the safety of products they use, natural products are highly favored. Compared with some synthetic substances, Eucommia ulmoides extract is relatively safe for human use. It is less likely to cause adverse reactions or side effects on the human body.

3.2 Good Compatibility

Compatibility with Other Ingredients: Eucommia ulmoides extract also has good compatibility with other ingredients. This property makes it very easy to be incorporated into various products. Whether it is in the medical field for formulating drugs or in the cosmetics industry for creating skin care products, it can blend well with other active ingredients or excipients. For example, in a multi - ingredient health supplement, it can work in harmony with vitamins, minerals, and other herbal extracts to achieve better overall health - promoting effects. In cosmetics, it can be combined with moisturizers, emulsifiers, and preservatives without causing any compatibility issues.

4. Manufacturing Processes of Eucommia ulmoides Extract

4.1 Raw Material Collection

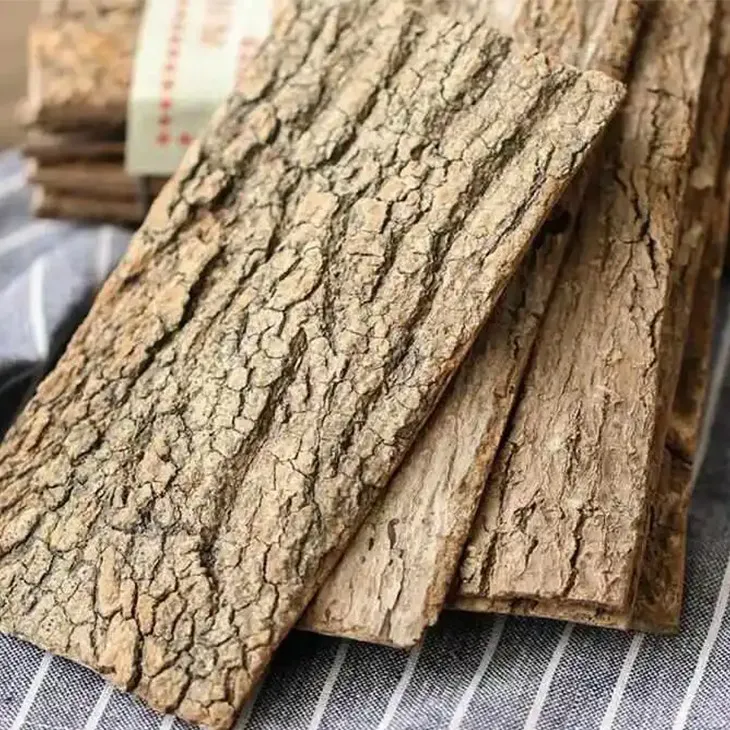

The first step in the manufacturing process of Eucommia ulmoides extract is raw material collection. High - quality Eucommia ulmoides bark or leaves are typically selected as the raw materials. The collection time and method are crucial factors that can affect the quality of the final extract. For example, the bark is usually collected during a certain period of the year when the active ingredient content is relatively high.

4.2 Extraction Methods

Solvent Extraction: One common extraction method is solvent extraction. In this process, a suitable solvent, such as ethanol or water, is used to extract the active ingredients from the raw materials. Ethanol extraction is often preferred because it can effectively dissolve a wide range of active components. The process involves soaking the raw materials in the solvent for a certain period, usually under controlled temperature and agitation conditions. For example, the raw materials may be soaked in ethanol at a temperature of around 50 - 60°C for several hours while being stirred gently to ensure thorough extraction.

Supercritical Fluid Extraction: Another advanced extraction method is supercritical fluid extraction. Supercritical carbon dioxide is commonly used as the supercritical fluid. This method has several advantages over traditional solvent extraction. It can achieve a higher extraction efficiency, and the extracted products are relatively pure. In the supercritical fluid extraction process, the pressure and temperature are carefully controlled to maintain the carbon dioxide in a supercritical state. The raw materials are then exposed to this supercritical carbon dioxide, which selectively extracts the active ingredients.

4.3 Purification

After the extraction step, purification is necessary to remove impurities from the extract. This can be achieved through various methods, such as filtration, chromatography, or centrifugation. Filtration can be used to remove large particles and debris. Chromatography, such as high - performance liquid chromatography (HPLC), can be used to separate and purify the active ingredients based on their different chemical properties. Centrifugation can also be used to separate heavier impurities from the extract.

4.4 Concentration

The final step in the manufacturing process is concentration. The purpose of concentration is to increase the concentration of the active ingredients in the extract. This can be done through methods such as evaporation or freeze - drying. Evaporation involves heating the extract under reduced pressure to remove the solvent, thereby increasing the concentration of the active components. Freeze - drying, on the other hand, involves freezing the extract and then removing the water or solvent by sublimation, which can also result in a concentrated product.

5. Conclusion

Eucommia ulmoides extract is a natural product with diverse applications, significant advantages, and a well - defined manufacturing process. Its applications in medicine and cosmetics are promising, and its natural and green nature along with good compatibility make it an attractive ingredient for various products. The manufacturing process, which includes raw material collection, extraction, purification, and concentration, ensures the quality and effectiveness of the final extract. As research continues, it is expected that Eucommia ulmoides extract will find even more applications and contribute more to human health and the beauty industry.

FAQ:

What are the main applications of Eucommia ulmoides extract in medicine?

Eucommia ulmoides extract in medicine can be used for health care. Its active ingredients are beneficial for improving blood circulation and enhancing the function of the immune system.

How does Eucommia ulmoides extract keep the skin young and healthy in the cosmetics industry?

In the cosmetics industry, Eucommia ulmoides extract has antioxidant properties. These properties can help to prevent skin aging and keep the skin in a healthy state.

What makes Eucommia ulmoides extract a relatively safe material for human use?

Eucommia ulmoides extract is a natural and green material. Compared with some synthetic substances, it is less likely to cause harmful effects on the human body, thus being relatively safe for human use.

Why is Eucommia ulmoides extract easy to be incorporated into various products?

Eucommia ulmoides extract has good compatibility with other ingredients. This characteristic allows it to be easily combined with different substances and incorporated into various products.

What are the main steps in the manufacturing process of Eucommia ulmoides extract?

The main steps in the manufacturing process of Eucommia ulmoides extract include raw material collection, extraction methods (such as solvent extraction or supercritical fluid extraction), purification, and concentration. These steps ensure the quality and effectiveness of the final extract.

Related literature

- The Bioactive Compounds and Potential Health Benefits of Eucommia ulmoides Extract"

- "Eucommia ulmoides Extract in Cosmetics: A Review of its Properties and Applications"

- "Manufacturing Techniques for High - Quality Eucommia ulmoides Extract"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Hops Extract

2024-11-11

-

Citrus Aurantii Extract

2024-11-11

-

Peppermint Oil

2024-11-11

-

Angelica sinensis extract

2024-11-11

-

Aguaje Extract

2024-11-11

-

Honeysuckle Pollen

2024-11-11

-

Echinacea Extract

2024-11-11

-

Fenugreek Extract Powder

2024-11-11

-

Epimedium extract powder

2024-11-11

-

Ginseng Root Extract

2024-11-11