- 0086-571-85302990

- sales@greenskybio.com

Astaxanthin Manufacturers.

2024-11-26

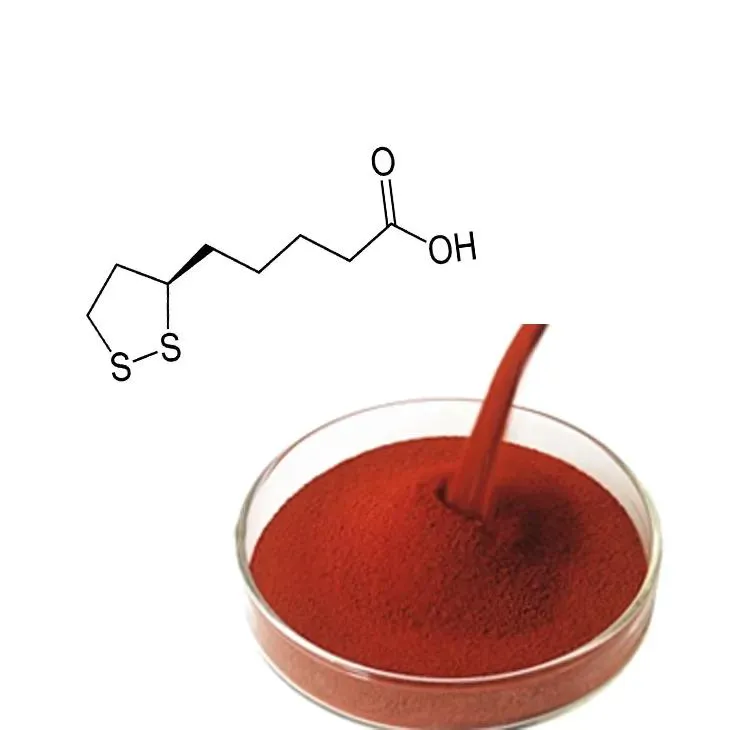

Introduction to Astaxanthin

Astaxanthin is a remarkable compound known for its vibrant red color and extremely potent antioxidant properties. It has found a wide range of applications in various industries such as health, beauty, and aquaculture. The demand for Astaxanthin has led to the emergence of numerous manufacturers around the world, each with their own production methods and challenges.

Natural Source - Krill - Based Astaxanthin Production

The Importance of Sustainable Harvesting

Manufacturers who produce astaxanthin from krill, a key natural source, have a complex production chain that begins with sustainable harvesting. Krill is abundant in the ocean, but over - harvesting can be detrimental to the marine ecosystem. Therefore, responsible manufacturers are very cautious about this. They implement strict environmental guidelines to ensure that the krill population remains stable. For example, they may limit the amount of krill harvested per season, use more selective harvesting methods, and closely monitor the krill population in the areas where they operate.

The Technical Extraction Process

Once the krill is harvested, the extraction process of astaxanthin is highly technical. It requires advanced equipment to isolate astaxanthin from krill without damaging its molecular structure. This is crucial because any damage to the molecular structure can reduce the effectiveness of astaxanthin as an antioxidant. The extraction process may involve several steps, such as crushing the krill to release the astaxanthin - containing components, followed by purification steps to separate astaxanthin from other substances present in krill.

Microalgae - Based Astaxanthin Production

Challenges in Large - Scale Cultivation

Manufacturers opting for microalgae - based astaxanthin production face their own set of challenges. One of the main challenges is in large - scale cultivation. Microalgae require specific environmental conditions to grow optimally. Water quality is of utmost importance. It needs to be free from contaminants and have the right balance of nutrients. Additionally, the CO2 supply must be carefully regulated. Too much or too little CO2 can affect the growth and astaxanthin production of microalgae. Light intensity is another factor that needs to be precisely managed. Insufficient light can lead to slow growth, while excessive light can cause damage to the microalgae cells.

The Crucial Purification Process

After cultivation, the purification process is crucial to obtain a high - grade astaxanthin product. Microalgae contain a variety of substances along with astaxanthin. The purification process aims to separate astaxanthin from these other components. This may involve techniques such as chromatography or filtration. Chromatography can be used to separate astaxanthin based on its chemical properties, while filtration can remove larger particles and impurities. The purification process needs to be highly efficient to ensure that the final product has a high purity level.

Synthetic Astaxanthin Production

Innovation in Chemical Synthesis

For synthetic astaxanthin manufacturers, innovation in chemical synthesis techniques is a constant pursuit. They aim to create astaxanthin with similar properties to the natural form while being cost - effective. This requires continuous research and development in the field of chemical synthesis. Manufacturers are constantly looking for new catalysts, reaction conditions, and synthesis routes to improve the quality and yield of synthetic astaxanthin. For example, they may be exploring new ways to control the stereochemistry of astaxanthin during synthesis to ensure that it has the same biological activity as the natural compound.

Addressing Market Perception

However, synthetic astaxanthin manufacturers also need to address concerns regarding the perception of synthetic products in the market. Some consumers prefer natural products and may be skeptical about the safety and effectiveness of synthetic astaxanthin. To overcome this, manufacturers need to be transparent about their production processes. They should provide scientific evidence to show that their synthetic astaxanthin is safe for consumption and has similar properties to the natural form. Additionally, they may need to invest in marketing strategies to educate consumers about the benefits of synthetic astaxanthin.

Regulatory Requirements for Astaxanthin Manufacturers

All astaxanthin manufacturers, regardless of their production method, are required to meet regulatory requirements. These requirements are in place to protect consumers and ensure the integrity of the astaxanthin market. Manufacturers must label their products accurately, indicating the source (whether it is from krill, microalgae, or synthetic), purity, and recommended usage. This helps consumers make informed decisions. For example, if a product contains a high level of impurities, consumers may choose to avoid it. Accurate labeling also helps regulatory authorities to monitor the market and ensure that manufacturers are following the rules.

Product Testing and Certification

In addition to labeling, manufacturers may also be required to conduct product testing. This can include tests to determine the purity, potency, and safety of astaxanthin. Some countries may require that products be certified by an independent laboratory before they can be sold. This further ensures the quality of astaxanthin products in the market. Manufacturers need to be aware of these requirements and ensure that their products meet the necessary standards.

Conclusion

Astaxanthin manufacturers play a vital role in the astaxanthin industry. Whether they produce astaxanthin from natural sources like krill or microalgae or through synthetic methods, they face various challenges. However, by adhering to sustainable practices, investing in research and development, and meeting regulatory requirements, they can contribute to the growth and integrity of the astaxanthin market. As the demand for astaxanthin continues to increase, manufacturers will need to continuously improve their production processes to meet the market's needs while maintaining high quality and safety standards.

FAQ:

What are the main challenges for krill - based astaxanthin manufacturers?

The main challenges for krill - based astaxanthin manufacturers include ensuring sustainable harvesting practices to avoid negative impacts on the marine ecosystem. Also, the extraction process is highly technical, requiring advanced equipment to isolate astaxanthin from krill without damaging its molecular structure.

What difficulties do microalgae - based astaxanthin manufacturers encounter?

Microalgae - based astaxanthin manufacturers face difficulties in large - scale cultivation. They need to precisely manage factors such as water quality, CO2 supply, and light intensity. Additionally, the purification process after cultivation is crucial for obtaining a high - grade astaxanthin product.

What is the focus of synthetic astaxanthin manufacturers?

The focus of synthetic astaxanthin manufacturers is on innovation in chemical synthesis techniques. They aim to produce astaxanthin with similar properties to the natural form while being cost - effective. However, they also need to deal with concerns about the market perception of synthetic products.

Why is it important for astaxanthin manufacturers to meet regulatory requirements?

It is important for astaxanthin manufacturers to meet regulatory requirements because they need to label their products accurately, indicating the source, purity, and recommended usage. This helps consumers make informed decisions and promotes the overall integrity of the astaxanthin market.

What are the applications of astaxanthin?

Astaxanthin has a wide range of applications in health, beauty, and aquaculture due to its vibrant red color and potent antioxidant properties.

Related literature

- Astaxanthin Production from Microalgae: Current State and Perspectives"

- "Sustainable Krill Harvesting for Astaxanthin Production"

- "Chemical Synthesis of Astaxanthin: Advances and Challenges"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Nutmeg Extract

2024-11-26

-

Europen Bilberry Extract

2024-11-26

-

Dandelion Leaf Extract

2024-11-26

-

Oyster Mushroom Extract Powder

2024-11-26

-

Troxerutin

2024-11-26

-

Carrageenan Extract Powder

2024-11-26

-

Kupilu Extract

2024-11-26

-

Lemon Extract

2024-11-26

-

Horse Chestnut Extract

2024-11-26

-

Hawthorn Extract

2024-11-26