- 0086-571-85302990

- sales@greenskybio.com

Chinese Diosmin Factories.

2024-11-27

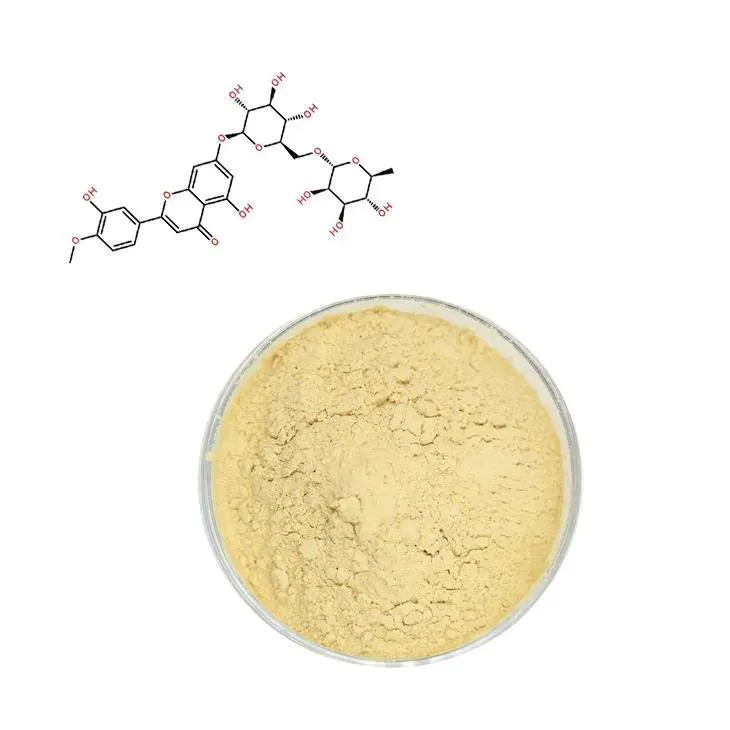

1. Introduction to Chinese Diosmin Factories

China has emerged as a significant player in the global Diosmin manufacturing landscape. Diosmin, a flavonoid with various applications in the pharmaceutical and nutraceutical industries, is produced in a large number of factories across the country. These factories are not only important for domestic consumption but also for international markets.

2. The Manufacturing Process: A Blend of Tradition and Modernity

2.1 Traditional Pharmaceutical Knowledge

The manufacturing process in Chinese diosmin factories is deeply rooted in traditional pharmaceutical knowledge. This knowledge has been passed down through generations and forms the basis for understanding the properties and potential uses of diosmin. For example, traditional Chinese medicine has long recognized the benefits of certain plants that contain diosmin - like compounds. This historical understanding helps in the initial sourcing of raw materials and in formulating the overall manufacturing approach.

2.2 Modern Technology Integration

State - of - the - art equipment is a hallmark of Chinese diosmin factories. Modern synthesis and purification techniques are employed to ensure high - quality production. Advanced chemical reactors are used for the synthesis of diosmin, allowing for precise control of reaction conditions such as temperature, pressure, and reaction time. This precision is crucial in obtaining a pure and consistent product.

In the purification stage, techniques like chromatography are utilized. Chromatography helps in separating diosmin from other impurities, resulting in a highly purified final product. These modern technologies not only improve the quality of diosmin but also increase the production efficiency, enabling Chinese factories to meet the growing global demand.

3. Stringent Quality Assurance

Quality is of utmost importance in the production of diosmin in Chinese factories. Stringent quality assurance procedures are in place to monitor every stage of production.

3.1 Raw Material Inspection

The process begins with a thorough inspection of raw materials. Only high - quality raw materials that meet strict standards are accepted. This includes testing for the presence of diosmin in the sourced plants, as well as screening for contaminants such as pesticides, heavy metals, and other harmful substances. Any raw material that fails to meet these criteria is rejected to prevent potential quality issues in the final product.

3.2 In - process Quality Control

During the manufacturing process, continuous quality control is carried out. This involves monitoring the reaction progress in the synthesis stage to ensure that the chemical reactions are proceeding as expected. In the purification process, samples are regularly taken and analyzed to confirm that the purification is effective and that the diosmin content and purity are within the specified ranges.

Advanced analytical techniques such as high - performance liquid chromatography (HPLC) and mass spectrometry are used for these in - process quality control checks. These techniques provide accurate and detailed information about the chemical composition of the product at each stage of production.

3.3 Final Product Testing

Before the diosmin product is released from the factory, comprehensive final product testing is conducted. This includes testing for physical properties such as solubility, melting point, and appearance. Chemical tests are also carried out to verify the diosmin content, purity, and the absence of any residual impurities.

Additionally, stability testing is performed to ensure that the product maintains its quality over time. This is especially important for products that may be stored for an extended period before use or during transportation. Only products that pass all these final tests are approved for sale.

4. Contribution to the Local Economy

4.1 Employment Generation

Chinese diosmin factories play a significant role in creating employment opportunities. These factories require a diverse range of skills, from chemical engineers and technicians to quality control specialists and administrative staff.

- Skilled workers are needed for operating the complex manufacturing equipment and conducting quality control tests.

- Research and development (R & D) teams are also employed to drive innovation in the manufacturing process and product development.

- Administrative and support staff are essential for the smooth running of the factory operations, including functions such as procurement, logistics, and human resources management.

4.2 Support to Related Industries

The diosmin manufacturing industry in China has a positive impact on related industries.

- It drives the demand for raw materials, which benefits the agricultural and botanical extraction industries. Suppliers of plants rich in diosmin are able to find a stable market, which encourages them to expand their production and improve their cultivation practices.

- The packaging industry also benefits as diosmin products require appropriate packaging for storage and transportation. This includes the production of bottles, caps, labels, and other packaging materials.

- Logistics and transportation companies are involved in the movement of raw materials to the factories and the distribution of the final products to domestic and international markets.

5. International Regulatory Compliance and Export

5.1 Adhering to International Standards

With the globalization of the pharmaceutical market, Chinese diosmin factories are increasingly focused on international regulatory compliance. They need to meet the quality and safety standards set by various countries and international organizations.

- For example, in the European Union, diosmin products must comply with the regulations of the European Medicines Agency (EMA). This includes requirements for good manufacturing practice (GMP), product registration, and quality control.

- In the United States, the Food and Drug Administration (FDA) has its own set of regulations that diosmin manufacturers must follow. This involves aspects such as pre - market approval, manufacturing facility inspections, and labeling requirements.

5.2 Export Opportunities and Market Expansion

As a result of their focus on international regulatory compliance, Chinese diosmin factories are able to export their products to a wide range of countries.

- Emerging markets in Asia, such as India, Indonesia, and Vietnam, are showing an increasing demand for diosmin products. Chinese factories are well - positioned to supply these markets due to their cost - effectiveness and proximity.

- In the Middle East, countries like Saudi Arabia and the United Arab Emirates are also potential markets for diosmin. The growing awareness of health and wellness in these regions is driving the demand for pharmaceutical and nutraceutical products containing diosmin.

- European and North American markets, although highly regulated, also offer significant export opportunities. Once Chinese factories meet the regulatory requirements of these regions, they can compete on the basis of quality and price.

6. Future Prospects and Challenges

6.1 Innovation and Product Diversification

Looking ahead, Chinese diosmin factories are expected to continue their focus on innovation. This includes research into new manufacturing techniques to further improve product quality and production efficiency.

- There is also potential for product diversification. For example, developing new formulations of diosmin - based products, such as combination products with other beneficial compounds. This could open up new market segments and meet the diverse needs of consumers.

6.2 Environmental Sustainability

As the global focus on environmental sustainability grows, Chinese diosmin factories will face challenges related to reducing their environmental impact.

- The manufacturing process may need to be optimized to reduce energy consumption and waste generation. This could involve the adoption of more energy - efficient equipment and the implementation of waste management strategies.

- Source of raw materials also needs to be sustainable. Ensuring that the plants used for diosmin extraction are sourced in an environmentally friendly way, such as through sustainable farming practices or forest management.

6.3 Competition in the Global Market

The global diosmin market is becoming increasingly competitive. Chinese factories will need to continuously improve their competitiveness.

- This could involve further cost - cutting measures while maintaining quality, such as optimizing the supply chain and reducing production costs.

- Building strong brand reputations in international markets will also be crucial. This requires consistent quality, effective marketing strategies, and good customer service.

FAQ:

What are the key features of Chinese diosmin factories?

Chinese diosmin factories combine traditional pharmaceutical knowledge with modern technology. They use advanced equipment for synthesis and purification, and have stringent quality assurance procedures to monitor production at every stage.

How do Chinese diosmin factories contribute to the local economy?

They create employment opportunities and support related industries, which helps to drive the local economy.

What is the significance of international regulatory compliance for Chinese diosmin factories?

Compliance with international regulations enables them to export their diosmin products to a wide range of countries, enhancing China's reputation in the global pharmaceutical manufacturing arena.

How is the quality of diosmin ensured in Chinese factories?

Stringent quality assurance procedures are in place in Chinese diosmin factories. These procedures monitor every stage of the production process, from synthesis to purification, to ensure high - quality diosmin is produced.

What role does innovation play in Chinese diosmin factories?

Innovation is at the forefront in Chinese diosmin factories. They use modern technology in the manufacturing process, which helps them to stay competitive and produce high - quality products.

Related literature

- Diosmin Production in China: A Comprehensive Review"

- "Quality Control in Chinese Diosmin Manufacturing"

- "The Impact of Chinese Diosmin Factories on the Global Market"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Peppermint Oil

2024-11-27

-

Tongkat Ali Extract Powder

2024-11-27

-

Green coffee bean Extract

2024-11-27

-

Beta Carotene

2024-11-27

-

Giant Knotweed Extract

2024-11-27

-

Kidney Bean Extract

2024-11-27

-

Rose Hip Extract

2024-11-27

-

Acerola Juice Powder

2024-11-27

-

Reishi mushroom extract

2024-11-27

-

Medicinal Marshmallow Extract

2024-11-27