- 0086-571-85302990

- sales@greenskybio.com

Extract astaxanthin by steam distillation.

2024-11-30

1. Introduction

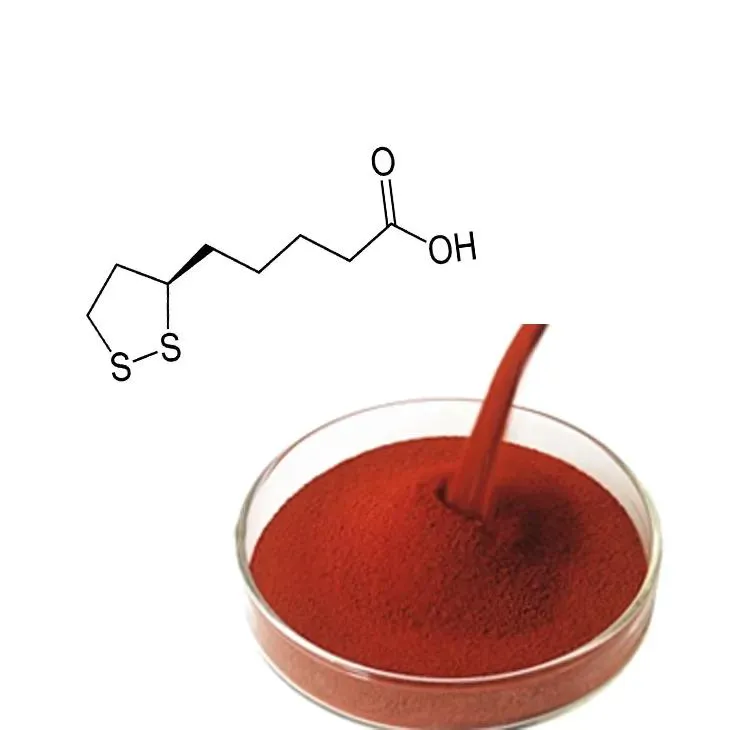

Astaxanthin, a powerful antioxidant, has been garnering significant attention in recent years. It is a carotenoid pigment that is responsible for the red color in various organisms such as salmon, shrimp, and some types of algae. Steam distillation has emerged as one of the methods for extracting Astaxanthin, and understanding this process is crucial for its efficient utilization in different industries.

2. The Scientific Basis of Steam Distillation for Astaxanthin Extraction

2.1. Principle of Steam Distillation

Steam distillation is based on the fact that the vapor pressure of a mixture of two immiscible liquids (in this case, the solvent and the astaxanthin - containing matrix) is equal to the sum of the vapor pressures of the individual components. When steam is passed through the astaxanthin - containing material, the volatile components along with astaxanthin (if it has some degree of volatility or is associated with volatile substances) are carried away. The steam and the volatiles are then condensed, and the resulting liquid can be further processed to isolate astaxanthin.

2.2. Interaction with Astaxanthin - Rich Sources

Astaxanthin is often found in natural sources such as microalgae like Haematococcus pluvialis. In these sources, astaxanthin may be present in a complex matrix. Steam distillation can help in breaking down this matrix by using the energy of the steam. The steam can penetrate the cell walls of the microalgae and release astaxanthin into the extraction medium. This is because the heat and pressure associated with steam can disrupt the cellular structures and lipid - protein complexes that may be holding astaxanthin.

3. The Steam Distillation Process for Astaxanthin Extraction

3.1. Preparation of the Sample

The first step in steam distillation for astaxanthin extraction is the preparation of the sample. If the source is microalgae, it needs to be harvested at the appropriate growth stage when the astaxanthin content is high. The harvested microalgae are then washed to remove any impurities such as dirt and other contaminants. After washing, the microalgae may be dried or used in a wet state depending on the requirements of the extraction process.

3.2. Steam Generation and Introduction

Next, steam is generated using a steam generator. The steam is then introduced into the extraction vessel containing the astaxanthin - rich sample. The rate of steam introduction is an important parameter as it can affect the efficiency of extraction. If the steam is introduced too slowly, the extraction may take a long time, and if it is too fast, it may cause the sample to be disrupted too violently, potentially leading to loss of astaxanthin or the formation of unwanted by - products.

3.3. Condensation and Collection

As the steam passes through the sample and carries the astaxanthin - related components, it then enters the condenser. The condenser cools the steam - vapor mixture, causing it to condense into a liquid. This liquid, which contains astaxanthin along with other substances, is collected in a receiver. The condenser temperature needs to be carefully controlled to ensure proper condensation.

3.4. Separation and Purification

Once the condensed liquid is collected, it needs to be further processed to separate and purify astaxanthin. This may involve techniques such as solvent extraction to remove unwanted lipids and other impurities. Chromatographic techniques can also be used to further purify astaxanthin and obtain a high - purity product.

4. Comparison with Other Extraction Methods

4.1. Solvent Extraction

Solvent extraction is a commonly used method for astaxanthin extraction. It involves using organic solvents such as hexane, ethanol, or acetone to dissolve astaxanthin from the source material. Compared to steam distillation, solvent extraction can be more selective in some cases as different solvents can target specific components. However, solvent extraction often requires a large amount of solvents, which can be expensive and may pose environmental risks due to solvent disposal. Steam distillation, on the other hand, uses steam, which is a more environmentally friendly medium, and may require less post - extraction processing to remove solvents.

4.2. Supercritical Fluid Extraction

Supercritical fluid extraction, typically using supercritical carbon dioxide, is another method for astaxanthin extraction. It has the advantage of being highly selective and can operate at relatively low temperatures, which is beneficial for heat - sensitive astaxanthin. However, the equipment for supercritical fluid extraction is expensive and requires high - pressure operation. Steam distillation is more cost - effective in terms of equipment requirements and can be more easily scaled up for large - scale production compared to supercritical fluid extraction.5. Significance of Steam - Distilled Astaxanthin in Various Industries

5.1. The Nutraceutical Industry

In the nutraceutical industry, astaxanthin is highly valued for its antioxidant properties. Steam - distilled astaxanthin can be used in dietary supplements. It helps in combating oxidative stress in the human body, which is associated with various health problems such as aging, heart disease, and neurodegenerative disorders. The high - purity astaxanthin obtained through steam distillation can be formulated into tablets, capsules, or liquid supplements.

5.2. The Cosmetic Industry

The cosmetic industry also benefits from steam - distilled astaxanthin. It is used in skincare products due to its antioxidant and anti - aging properties. Astaxanthin can protect the skin from damage caused by UV radiation, free radicals, and environmental pollutants. It can be incorporated into creams, lotions, and serums to improve skin elasticity, reduce wrinkles, and enhance skin tone.

5.3. The Aquaculture Industry

In aquaculture, astaxanthin is an important pigment for fish and shrimp. Feeding astaxanthin - supplemented diets to salmonids and crustaceans can improve their coloration, which is highly desirable in the market. Steam - distilled astaxanthin can be used as a feed additive in aquaculture. It can also enhance the health and immunity of the cultured organisms, leading to better growth and survival rates.6. Challenges and Future Perspectives

6.1. Challenges in Steam Distillation of Astaxanthin

One of the main challenges in steam distillation of astaxanthin is achieving high extraction efficiency while maintaining the integrity of astaxanthin. High temperatures during steam distillation can potentially degrade astaxanthin, so careful control of the process parameters such as temperature and time is required. Another challenge is the presence of impurities in the final product, which may require more advanced purification techniques.

6.2. Future Perspectives

Future research in steam distillation of astaxanthin could focus on optimizing the process parameters to improve extraction efficiency and product quality. There could also be investigations into new extraction aids or modifiers that can enhance the interaction between steam and the astaxanthin - containing matrix. Additionally, the development of more sustainable and cost - effective steam distillation processes could open up new opportunities for the large - scale production of astaxanthin.7. Conclusion

Steam distillation offers a viable method for astaxanthin extraction. It has a scientific basis that allows for the extraction of astaxanthin from its natural sources. When compared to other extraction methods, it has its own set of advantages in terms of cost - effectiveness and environmental friendliness. The significance of steam - distilled astaxanthin in various industries such as nutraceuticals, cosmetics, and aquaculture cannot be overstated. However, there are still challenges to be overcome in order to fully realize the potential of steam distillation for astaxanthin extraction. With further research and development, this method could play an even more important role in the production of high - quality astaxanthin in the future.

FAQ:

What is the principle of astaxanthin extraction by steam distillation?

Steam distillation for astaxanthin extraction is based on the different volatilities of substances. Astaxanthin can be separated from the raw material matrix as steam is passed through. The heat and steam cause the components with different boiling points to vaporize at different rates. Astaxanthin, being relatively stable under these conditions, can be carried along with the steam and then condensed and collected.

How does steam distillation compare to solvent extraction for astaxanthin?

Steam distillation is a more environmentally friendly method compared to solvent extraction. Solvent extraction often requires the use of organic solvents which may be toxic and require additional purification steps to remove solvent residues. In contrast, steam distillation uses only steam and water, reducing the risk of chemical contamination. However, solvent extraction may sometimes achieve higher extraction yields in certain cases, but the quality of the astaxanthin obtained by steam distillation may be purer in terms of the absence of solvent - related impurities.

What are the main steps in the steam distillation process for astaxanthin extraction?

The main steps include preparing the raw material containing astaxanthin. Then, steam is introduced into the system. As the steam passes through the raw material, it causes the astaxanthin to vaporize. The vapor - rich mixture then moves to a condenser where it is cooled down, and the astaxanthin - rich condensate is collected. Finally, further purification steps may be carried out to obtain high - purity astaxanthin.

In which industries is steam - distilled astaxanthin mainly used?

Steam - distilled astaxanthin has wide applications. In the food industry, it is used as a natural colorant and antioxidant in food products such as fish feed to enhance the color of fish flesh. In the cosmetic industry, it is added to skincare products due to its antioxidant properties which can help protect the skin from oxidative damage. In the pharmaceutical industry, it shows potential in various health - promoting applications such as anti - inflammatory and antioxidant therapies.

What are the challenges in astaxanthin extraction by steam distillation?

One of the main challenges is achieving a high extraction yield. Since astaxanthin may not be completely vaporized or may be lost during the process, optimizing the extraction conditions such as temperature, pressure, and steam flow rate is crucial. Another challenge is the potential degradation of astaxanthin during the distillation process due to high temperatures, so careful control of the process parameters is required to ensure the quality of the extracted astaxanthin.

Related literature

- Steam Distillation in Natural Product Extraction: A Review"

- "Astaxanthin: Sources, Extraction and Applications"

- "Comparative Study of Different Extraction Methods for Astaxanthin"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Shikonin

2024-11-30

-

Red Wine Extract

2024-11-30

-

Green Tea Extract

2024-11-30

-

Grapefruit Seed Extract Powder

2024-11-30

-

Sophora Flavescens Root Extract

2024-11-30

-

Oat Straw Extract Powder

2024-11-30

-

Yohimbine Bark Extract

2024-11-30

-

Nettle leaf extract

2024-11-30

-

Acerola Extract

2024-11-30

-

Grape Leaf Extract

2024-11-30