- 0086-571-85302990

- sales@greenskybio.com

Extraction process of saw palmetto extract.

2024-12-01

1. Introduction

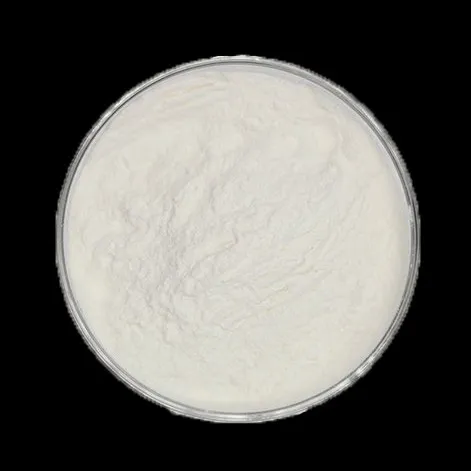

Saw Palmetto Extract has gained significant attention in various fields, especially in the area of health and wellness. The extraction process of Saw Palmetto Extract is a complex yet fascinating procedure that involves multiple steps to ensure the final product's quality, purity, and potency. This article will delve into the details of each step involved in the extraction process.

2. Harvesting of Saw Palmetto Fruits

Harvesting is the first and crucial step in the extraction of Saw Palmetto Extract. The saw palmetto fruits are typically harvested when they reach an appropriate level of maturity. This is important as it directly affects the quality of the extract. The harvesting process needs to be carried out carefully to avoid damaging the fruits. Workers usually pick the fruits by hand or use specialized harvesting tools. The time of harvesting also plays a role. For example, in certain regions, the best time for harvesting saw palmetto fruits is during the fall season when the fruits are fully developed.

3. Sorting of Fruits

Once the fruits are harvested, the next step is sorting. Sorting is essential to remove any damaged or unripe fruits. Damaged fruits may introduce contaminants or have a lower content of the desired compounds, while unripe fruits may not contain the full spectrum of active ingredients.

The sorting process can be carried out manually or with the help of mechanical sorting devices. In manual sorting, workers carefully examine each fruit and separate the good ones from the bad. Mechanical sorting devices, on the other hand, can use parameters such as size, shape, and density to separate the fruits. This step helps to ensure that only high - quality fruits are used for the extraction process.

4. Steam Distillation for Essential Oil Extraction

After sorting, steam distillation can be utilized to extract essential oils from the saw palmetto fruits initially. Steam distillation is a well - known method in the extraction of essential oils.

In this process, steam is passed through the fruits. The heat from the steam causes the essential oils to vaporize. These vapors are then collected and condensed back into a liquid form. The principle behind this is that the essential oils have different boiling points compared to the other components in the fruits. By carefully controlling the temperature and pressure during the steam distillation process, the essential oils can be effectively separated from the fruits.

The essential oils obtained from saw palmetto fruits through steam distillation have their own unique properties and potential applications. They may be used in aromatherapy, as flavoring agents, or in some cases, as part of the overall saw palmetto extract for its health - promoting properties.

5. Solvent - Based Extraction of the Remaining Solid Material

After the essential oils are extracted through steam distillation, the remaining solid material still contains valuable components. Solvent - based extraction methods are then employed to further extract these components.

There are different solvents that can be used for this purpose, such as ethanol or hexane. The choice of solvent depends on various factors, including the solubility of the desired compounds, safety considerations, and environmental impact. For example, ethanol is a relatively safe and commonly used solvent in the extraction of natural products.

In the solvent - based extraction process, the solid material is soaked in the solvent for a certain period. The solvent then dissolves the desired compounds from the solid material. This solution is then separated from the remaining solid residue. The solvent - based extraction method is effective in extracting a wide range of compounds from the saw palmetto fruits, including fatty acids and sterols.

6. Ultrafiltration for Component Separation

Once the solvent - based extraction is complete, ultrafiltration is carried out to separate different molecular weight components. Ultrafiltration is a membrane - based separation technique.

Membranes with specific pore sizes are used in ultrafiltration. These membranes allow smaller molecules to pass through while retaining larger molecules. In the context of saw palmetto extract, this helps in separating different types of compounds based on their molecular weights. For example, it can separate smaller bioactive molecules from larger polymeric substances.

Ultrafiltration is a gentle and efficient method of separation. It can help in purifying the extract by removing unwanted larger molecules or aggregates. This step is important for obtaining a more refined and pure saw palmetto extract.

7. Concentration under Reduced Pressure

After ultrafiltration, the saw palmetto extract is then concentrated under reduced pressure. Reduced - pressure concentration, also known as vacuum concentration, is a method that helps in removing the solvent and increasing the concentration of the active components in the extract.

By reducing the pressure, the boiling point of the solvent is lowered. This allows the solvent to be evaporated more easily at a lower temperature. This is beneficial as it helps to preserve the integrity of the active components in the extract, which may be sensitive to high temperatures. The concentrated extract has a higher content of the desired compounds per unit volume, making it more suitable for various applications such as in the formulation of dietary supplements or pharmaceutical products.

8. Quality Control throughout the Process

Quality control measures are constantly applied throughout the entire extraction process of saw palmetto extract. Quality control starts from the very beginning, with the inspection of the raw materials (the saw palmetto fruits).

During the extraction steps, parameters such as temperature, pressure, and solvent concentration are carefully monitored. For example, in steam distillation, the temperature and pressure need to be maintained within a specific range to ensure the proper extraction of essential oils. In solvent - based extraction, the concentration of the solvent and the extraction time are controlled to optimize the extraction of desired compounds.

After each step, the intermediate products are analyzed for their composition and quality. Analytical techniques such as high - performance liquid chromatography (HPLC) or gas chromatography - mass spectrometry (GC - MS) may be used to identify and quantify the compounds in the extract. These techniques help in ensuring that the final saw palmetto extract meets the required purity and potency standards.

In addition to chemical analysis, physical properties such as the appearance, odor, and solubility of the extract are also evaluated. Any deviation from the expected quality parameters may lead to further investigation and corrective actions. Quality control is essential to produce a high - quality saw palmetto extract that is safe and effective for its intended uses.

9. Conclusion

The extraction process of saw palmetto extract is a multi - step and intricate procedure. From the harvesting of the fruits to the final quality control checks, each step is crucial in obtaining a high - quality, pure, and potent extract. The proper execution of these steps ensures that saw palmetto extract can be used effectively in various applications, whether it is in the field of health supplements, traditional medicine, or other related industries. As research on saw palmetto and its extract continues, further improvements in the extraction process may be expected to enhance the quality and potential benefits of this valuable natural product.

FAQ:

What is the first step in the extraction process of saw palmetto extract?

The first step in the extraction process of saw palmetto extract is the harvesting of saw palmetto fruits.

Why are the fruits sorted during the extraction process?

The fruits are sorted during the extraction process to remove any damaged or unripe ones.

What method can be used to extract essential oils from the fruits initially?

Steam distillation can be used to extract essential oils from the fruits initially.

How are different molecular weight components separated during the extraction process?

Ultrafiltration is carried out to separate different molecular weight components during the extraction process.

What is done to ensure the quality of the final saw palmetto extract?

Quality control measures are constantly applied throughout the process to ensure the purity and potency of the final saw palmetto extract.

Related literature

- Saw Palmetto Extract: A Comprehensive Review of its Extraction, Composition and Therapeutic Applications"

- "Optimization of the Extraction Process of Saw Palmetto (Serenoa repens) for Enhanced Bioactive Compounds Recovery"

- "Recent Advances in the Extraction Technologies of Saw Palmetto Extracts"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Lavender Extract

2024-12-01

-

Curcumin Extract

2024-12-01

-

Lemon Balm Extract

2024-12-01

-

Giant Knotweed Extract

2024-12-01

-

Elderberry Extract

2024-12-01

-

Artichoke Leaf Extract

2024-12-01

-

Rose Hip Extract

2024-12-01

-

Chaste Berry Extract

2024-12-01

-

Black Pepper Extract

2024-12-01

-

Carrageenan Extract Powder

2024-12-01