- 0086-571-85302990

- sales@greenskybio.com

How to Extract Eucommia ulmoides Extract from Plants?

2024-11-30

1. Introduction

Eucommia ulmoides, a plant native to China, has been highly regarded for its numerous potential health benefits. These benefits range from anti - inflammatory properties to potential contributions in improving cardiovascular health. As a result, the extraction of its active components has become an important area of research and application in various industries, such as the pharmaceutical, nutraceutical, and cosmetic industries. This article will focus on the detailed process of extracting Eucommia Ulmoides Extract from the plants.

2. Harvesting of Eucommia ulmoides

2.1. Optimal Time for Harvesting

The first step in the extraction process is the proper harvesting of Eucommia ulmoides. The timing of harvesting is crucial as it can significantly affect the quality and quantity of the extractable components. Generally, the best time to harvest Eucommia ulmoides is during the late autumn or early winter. At this time, the plant has accumulated a relatively high amount of active substances, such as flavonoids, lignans, and polysaccharides.2.2. Selection of Plant Parts

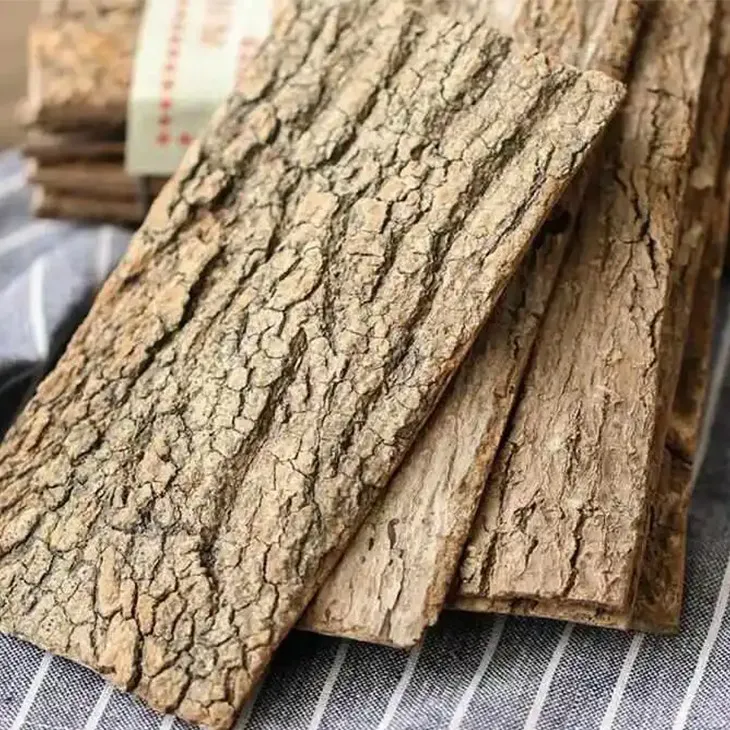

Different parts of the Eucommia ulmoides plant can be used for extraction. The bark is the most commonly used part due to its high content of bioactive compounds. However, in recent years, research has also shown that the leaves of Eucommia ulmoides also contain valuable substances. When harvesting, it is necessary to select healthy plants and parts to ensure the quality of the raw materials.

3. Initial Preparation

3.1. Cleaning

After harvesting, the plant materials need to be thoroughly cleaned to remove dirt, debris, and other impurities. This can be done by washing the materials with clean water. It is important to ensure that all foreign substances are removed as they can interfere with the extraction process and affect the quality of the final extract.3.2. Drying

Once cleaned, the plant materials should be dried. Drying can be carried out under natural conditions, such as in the shade or in a well - ventilated area. However, to speed up the process and ensure better control over the drying conditions, artificial drying methods, such as using a drying oven at a low temperature (usually around 40 - 60°C), can also be used. Drying helps to reduce the moisture content of the plant materials, which is beneficial for subsequent processing steps, such as grinding.3.3. Grinding

Grinding is an important mechanical method for the initial preparation of Eucommia ulmoides. The dried plant materials are ground into a fine powder. This increases the surface area of the materials, which in turn enhances the contact between the plant substances and the extraction solvent during the extraction process. A grinder or a mill can be used for this purpose. The particle size of the ground powder should be as uniform as possible to ensure consistent extraction results.

4. Extraction Methods

4.1. Soxhlet Extraction

Soxhlet extraction is a traditional and well - established method for extracting Eucommia Ulmoides Extract.- Principle: In Soxhlet extraction, the ground plant material is placed in a Soxhlet extractor. The extraction solvent, which is usually a suitable organic solvent such as ethanol or methanol, is continuously recycled through the plant material. The solvent vaporizes in the distillation flask, rises through the Soxhlet apparatus, and condenses back into the extraction chamber containing the plant material. This continuous cycling of the solvent allows for efficient extraction of the soluble components from the plant material.

- Procedure:

- Weigh a certain amount of the ground Eucommia ulmoides powder and place it in a Soxhlet thimble.

- Fill the Soxhlet extraction apparatus with the selected extraction solvent to a suitable level.

- Connect the apparatus to a heat source, usually a heating mantle, and start the extraction process. The extraction typically takes several hours to complete, depending on the nature of the plant material and the extraction solvent used.

- Advantages and Disadvantages:

- Advantages: It is a reliable method that can extract a wide range of compounds from the plant material. It is also relatively easy to set up and operate.

- Disadvantages: The use of organic solvents may pose safety risks and environmental concerns. Additionally, the extraction process can be time - consuming.

4.2. Ultrasonic - Assisted Extraction

Ultrasonic - assisted extraction has emerged as a popular modern technique for extracting Eucommia Ulmoides Extract.- Principle: Ultrasonic waves are applied to the extraction system. These ultrasonic waves create cavitation bubbles in the extraction solvent. When these bubbles collapse, they generate high - intensity shock waves and micro - jets. These physical phenomena can disrupt the cell walls of the plant material, thereby enhancing the release of the intracellular components into the extraction solvent. As a result, the extraction efficiency is significantly improved without the need for high - temperature extraction.

- Procedure:

- Place the ground Eucommia ulmoides powder in a suitable container.

- Add the extraction solvent to the container.

- Immerse an ultrasonic probe or place the container in an ultrasonic bath and start the ultrasonic treatment. The treatment time and power settings depend on the specific requirements of the extraction, but typically range from 10 - 60 minutes.

- Advantages and Disadvantages:

- Advantages: It can significantly reduce the extraction time compared to traditional methods. It also has the potential to improve the extraction yield and quality of the extract. Moreover, it is a relatively clean and energy - efficient method as it does not require high - temperature heating.

- Disadvantages: The equipment for ultrasonic - assisted extraction can be relatively expensive. Also, the optimization of extraction parameters, such as ultrasonic power and treatment time, may require more experimental work.

5. Filtration

After the extraction process, whether it is by Soxhlet extraction or ultrasonic - assisted extraction, the resulting solution contains not only the desired Eucommia ulmoides extract but also various impurities, such as plant debris, undissolved solids, and solvent - soluble impurities. Filtration is therefore necessary to remove these impurities.

5.1. Types of Filters

There are different types of filters that can be used for this purpose.- Filter Paper: This is a simple and commonly used filter. It is suitable for removing relatively large particles and debris. However, for very fine particles or colloidal impurities, it may not be sufficient.

- Membrane Filters: Membrane filters with different pore sizes can be selected according to the size of the impurities to be removed. They can effectively remove fine particles and microorganisms, ensuring a high - purity extract.

5.2. Filtration Process

The extraction solution is poured through the filter. The filtrate, which is the solution that passes through the filter, contains the purified Eucommia ulmoides extract, while the residue on the filter is the removed impurities. To ensure complete filtration, the filtration process may be repeated several times if necessary.6. Evaporation and Drying

6.1. Evaporation

The filtrate obtained after filtration still contains a large amount of solvent. Evaporation is carried out to remove the solvent and concentrate the extract. This can be achieved by using a rotary evaporator. The rotary evaporator operates under reduced pressure, which allows the solvent to be evaporated at a relatively low temperature. This helps to preserve the integrity of the active components in the extract.6.2. Drying

After evaporation, the remaining concentrated extract may still contain some moisture. Drying is the final step to obtain a dry Eucommia ulmoides extract. Drying can be done using methods such as freeze - drying or vacuum drying. Freeze - drying is a preferred method as it can maintain the structure and activity of the bioactive compounds in the extract. Vacuum drying is also effective and can be carried out at a relatively low temperature to avoid thermal degradation of the extract.7. Analysis and Utilization

Once the Eucommia ulmoides extract has been obtained, it can be further analyzed and utilized.

7.1. Analysis

Various analytical techniques can be used to determine the composition and quality of the extract.- High - Performance Liquid Chromatography (HPLC): HPLC can be used to separate and quantify the different components in the extract, such as flavonoids and lignans.

- Gas Chromatography - Mass Spectrometry (GC - MS): This technique is suitable for analyzing volatile components in the extract.

- Spectroscopic Methods: Such as ultraviolet - visible spectroscopy (UV - Vis) and infrared spectroscopy (IR), which can provide information about the functional groups and chemical structure of the extract components.

7.2. Utilization

The Eucommia ulmoides extract has a wide range of applications.- Pharmaceutical Industry: It can be used as a raw material for the development of drugs for treating various diseases, such as hypertension and osteoporosis.

- Nutraceutical Industry: As a dietary supplement, it can be added to foods or health products to provide potential health benefits.

- Cosmetic Industry: The extract can be incorporated into cosmetics for its antioxidant and skin - conditioning properties.

8. Conclusion

The extraction of Eucommia ulmoides extract from plants is a multi - step process that involves harvesting, initial preparation, extraction, filtration, evaporation, and drying. Different extraction methods, such as Soxhlet extraction and ultrasonic - assisted extraction, have their own advantages and disadvantages. The choice of method depends on various factors, including the desired quality and quantity of the extract, cost, and environmental considerations. Once obtained, the Eucommia ulmoides extract can be analyzed and utilized in different industries, contributing to the development of various products with potential health benefits.

FAQ:

Question 1: What is the first step in extracting Eucommia ulmoides extract?

The first step in extracting Eucommia ulmoides extract is the proper harvesting of Eucommia ulmoides plants.

Question 2: What are the common mechanical methods for initial preparation?

Grinding is a common mechanical method for the initial preparation of Eucommia ulmoides for extraction.

Question 3: Why is Soxhlet extraction used?

Soxhlet extraction is a traditional yet effective method for obtaining Eucommia ulmoides extract.

Question 4: What is the advantage of ultrasonic - assisted extraction?

The advantage of ultrasonic - assisted extraction is its ability to enhance extraction efficiency without using high temperatures.

Question 5: Why is filtration necessary?

Filtration is necessary to remove impurities from the extracted solution.

Question 6: What are the final steps in getting the Eucommia ulmoides extract?

The final steps in getting the Eucommia ulmoides extract are evaporation and drying of the filtered solution.

Related literature

- Studies on the Chemical Constituents and Bioactivities of Eucommia ulmoides Extracts"

- "Optimization of the Extraction Process of Eucommia ulmoides Extract"

- "New Insights into the Extraction and Application of Eucommia ulmoides Extract"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

100% Pure Natural Troxerutin.

2024-11-30

-

Nature's Bounty Marshmallow Root Extract.

2024-11-30

-

Vitamin B6 Suppliers

2024-11-30

-

Organic deer antler extract powder factory.

2024-11-30

-

Certified organic coenzyme Q10.

2024-11-30

-

Australian Organic Propolis Extract Powder.

2024-11-30

-

The extraction process of vitamin B6.

2024-11-30

-

Yam Extract

2024-11-30

-

Beetroot juice Powder

2024-11-30

-

Honeysuckle Pollen

2024-11-30

-

Apricot Powder

2024-11-30

-

Berberis aristata Extract

2024-11-30

-

Polygonum Cuspidatum Extract

2024-11-30

-

Sea buckthorn oil

2024-11-30

-

Saffron Extract Powder

2024-11-30

-

Fenugreek Extract Powder

2024-11-30

-

Green Tea Extract

2024-11-30