- 0086-571-85302990

- sales@greenskybio.com

How to Extract Garcinia Cambogia Extract from Plants?

2024-11-30

Introduction

Garcinia Cambogia Extract has become quite popular in recent times. It is mainly known for its potential role in weight management and has also been associated with other possible health benefits. Extracting this valuable extract from plants is a multi - step process that requires careful attention to detail.

Raw Material Selection

The first and very crucial step in extracting Garcinia Cambogia Extract is the selection of the raw material. The Garcinia cambogia fruits are the starting point of this extraction process.

Quality of the Fruits: It is essential that the fruits are of high quality. They should be ripe. Ripe fruits are likely to have a higher concentration of the desired compounds. Additionally, the fruits must be free from diseases and pests. Diseased or pest - affected fruits may have altered chemical compositions and could introduce contaminants into the extract.

Source of the Plants: The source of the Garcinia cambogia plants also matters. Plants that are grown in suitable climates and soil conditions are preferred. For example, the plant thrives in warm and humid climates. The soil should be well - drained and rich in nutrients. Fruits from plants grown in such ideal conditions are more likely to yield a better - quality extract.

Fruit Preparation

Once the appropriate fruits have been selected, the next step is to prepare them for extraction.

Washing

The fruits are initially washed thoroughly. This is done to remove any dirt, debris, or impurities that may be present on the surface of the fruits. Any foreign matter left on the fruits could contaminate the extract during the subsequent steps.

Drying

After washing, the fruits are dried. There are two main methods for drying Garcinia cambogia fruits:

- Natural Drying in the Sun: This is a traditional method. The fruits are spread out in a clean, dry area under the sun. However, this method may take longer and is dependent on the weather conditions. The advantage is that it is a more natural process and may preserve some of the natural properties of the fruits better.

- Mechanical Drying: Using mechanical drying methods such as dryers can speed up the drying process. This is especially useful when large quantities of fruits need to be dried. Mechanical drying allows for more control over the drying conditions such as temperature and humidity, which can ensure a more consistent drying result.

The drying process helps to reduce the moisture content of the fruits. This is important for the extraction process as excessive moisture can interfere with the extraction of the active compounds.

Extraction Method - Solvent Extraction

Solvent extraction is a commonly used method for obtaining Garcinia Cambogia Extract.

Solvent Selection

Ethanol and Ethyl Acetate: These are two of the suitable solvents often used for this extraction. Ethanol is a relatively safe and commonly available solvent. Ethyl acetate also has good extraction properties and is often used in the pharmaceutical and food industries for extraction purposes.

Grinding and Mixing

- The dried Garcinia cambogia fruits are first ground into a fine powder. This increases the surface area of the fruits, allowing for better interaction with the solvent during the extraction process.

- Once the fruits are ground into a powder, it is mixed with the selected solvent in a specific ratio. The ratio is determined based on factors such as the concentration of the active compounds desired and the efficiency of the extraction process.

- The mixture is then stirred continuously. This stirring is usually carried out for a period of several hours. The continuous stirring ensures that the solvent can fully interact with the powdered fruits and extract the maximum amount of the active compounds.

Filtration

After the extraction process through stirring, the mixture is filtered. The purpose of filtration is to separate the liquid extract (which contains the active compounds) from the solid residue. Filtration can be done using various methods such as filter paper filtration or using filtration equipment in a laboratory or industrial setting.

Purification

The extract obtained after filtration may still contain other impurities along with the desired Garcinia cambogia compounds. Therefore, purification is a necessary step.

Chromatography: Chromatography is one of the purification techniques that can be used. There are different types of chromatography such as column chromatography or high - performance liquid chromatography (HPLC). In chromatography, the components of the extract are separated based on their different chemical properties. This allows for the isolation and obtaining of a pure form of the Garcinia cambogia extract. Purification is crucial as it ensures the quality and effectiveness of the final product. A pure extract is more likely to have the desired physiological effects and is also safer for consumption in the case of products like dietary supplements.

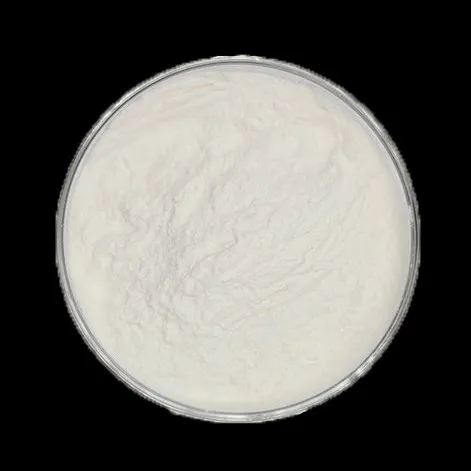

Concentration and Drying

- Concentration: After purification, the extract is concentrated. The purpose of concentration is to increase the concentration of the active compounds in the extract. This can be done through methods such as evaporation, where the solvent is removed under controlled conditions to leave behind a more concentrated form of the extract.

- Drying: Finally, the concentrated extract is dried again. Drying is usually carried out to obtain a powder form of Garcinia cambogia extract. This powder form is more stable and easier to handle and store. It can also be used in various applications such as in the formulation of dietary supplements, where it can be encapsulated or added to other ingredients.

Conclusion

The extraction of Garcinia cambogia extract from plants is a complex process that involves multiple steps. Starting from the careful selection of raw materials, through fruit preparation, solvent extraction, purification, and finally concentration and drying, each step plays a vital role in obtaining a high - quality extract. The resulting Garcinia cambogia extract has the potential to be used in various applications, especially in the field of health and wellness, particularly in relation to weight management. However, it is important to note that while Garcinia cambogia extract has shown potential benefits, further research is still needed to fully understand its effects and ensure its safe and effective use.

FAQ:

What are the key factors in raw material selection for Garcinia cambogia extract?

The key factors in raw material selection for Garcinia cambogia extract are choosing high - quality fruits that are ripe and free from diseases and pests. It is also essential to select fruits from plants grown in suitable climates and soil conditions.

Why is drying important in the fruit preparation stage?

Drying is important in the fruit preparation stage because it reduces the moisture content of the fruits. This helps in the extraction process as it can make the extraction more efficient.

What solvents are commonly used in solvent extraction of Garcinia cambogia extract?

Ethanol or ethyl acetate are commonly used solvents in the solvent extraction of Garcinia cambogia extract.

How does purification ensure the quality of Garcinia cambogia extract?

Purification, such as through chromatography, ensures the quality of Garcinia cambogia extract by separating the desired compounds from other impurities. This results in a pure form of the extract, which is crucial for its effectiveness in applications such as dietary supplements.

What is the purpose of concentration and drying at the end of the extraction process?

The purpose of concentration is to increase the concentration of the active compounds in the extract. Drying at the end is to obtain a powder form of Garcinia cambogia extract, which can be used in various applications like in dietary supplements.

Related literature

- The Extraction and Potential Health Benefits of Garcinia cambogia"

- "Garcinia cambogia: An Overview of its Extraction Methods and Quality Control"

- "Advances in Garcinia cambogia Extract Production"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Yam Extract

2024-11-30

-

Cranberry Extract

2024-11-30

-

Stevia Extract

2024-11-30

-

Withania Somnifera Extract

2024-11-30

-

Bamboo Leaf extract

2024-11-30

-

Fenugreek Extract Powder

2024-11-30

-

Ivy Extract

2024-11-30

-

Gynostemma pentaphyllum extract

2024-11-30

-

Nettle Root Extract

2024-11-30

-

Rosemary extract

2024-11-30