- 0086-571-85302990

- sales@greenskybio.com

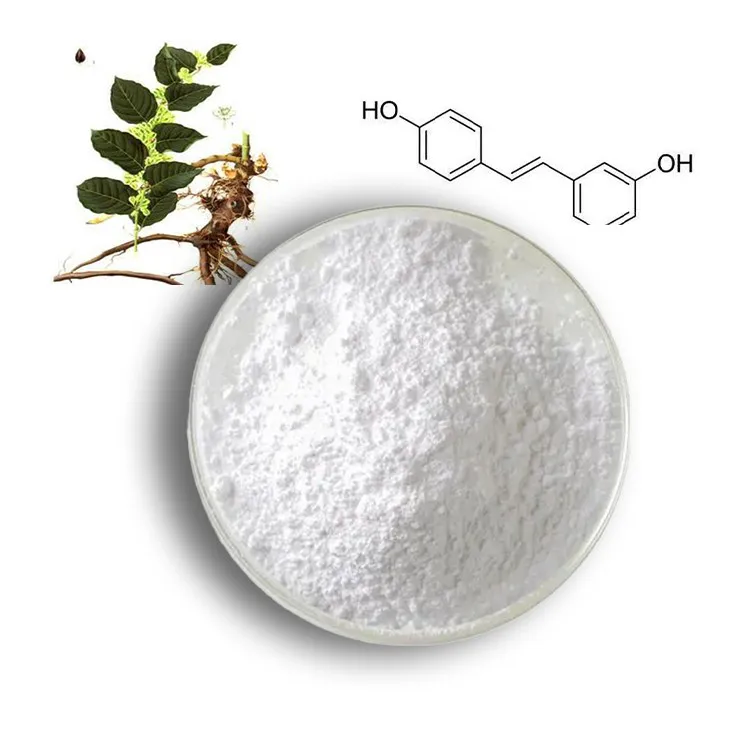

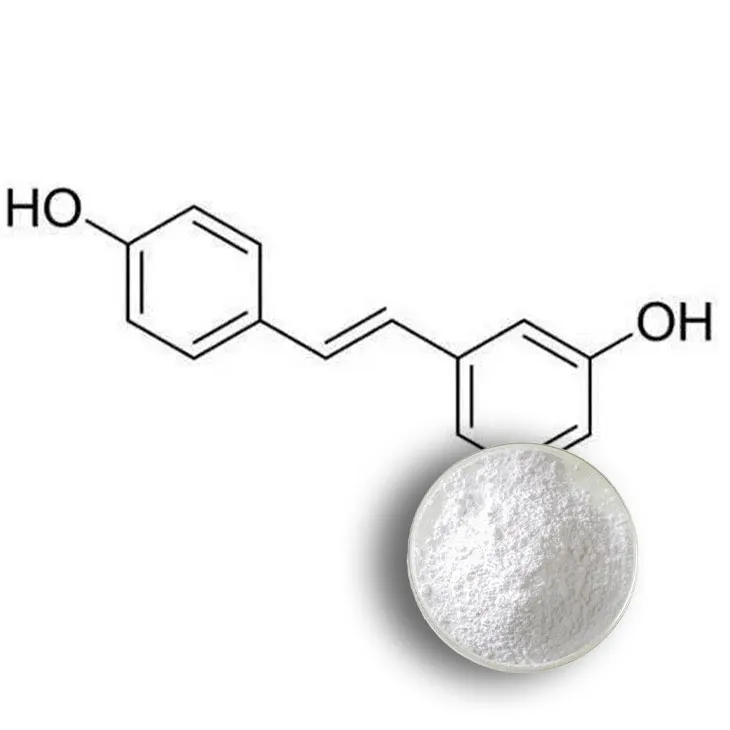

How to extract resveratrol extract from plants?

2024-12-01

1. Introduction

Resveratrol is a natural compound that has attracted significant attention due to its numerous health - promoting properties. It is found in various plants, and extracting it from these sources can be a complex but rewarding process. This article will explore in detail the methods of extracting Resveratrol extract from plants.

2. Selecting Plant Sources

The first step in extracting resveratrol is to select appropriate plant sources. Different plants contain different levels of resveratrol, and some are more commonly used for extraction due to their relatively high content.

2.1 Grapes

Grapes are one of the most well - known sources of resveratrol. The skin of grapes, in particular, contains a significant amount of this compound. Red grapes are often preferred as they tend to have a higher resveratrol content compared to white grapes. This is because resveratrol is produced in grapes as a response to stress, such as fungal infections, and red grapes are more likely to be exposed to such stressors.

2.2 Peanuts

Peanuts also contain resveratrol. Although the levels may not be as high as in grapes in some cases, they are still a viable source, especially in regions where peanuts are abundantly grown. The resveratrol in peanuts is mainly present in the skin and the underlying layers.

2.3 Berries

Certain berries, such as blueberries, cranberries, and mulberries, are also sources of resveratrol. These berries are rich in various antioxidants, and resveratrol is one of the important components. Berries are often considered a healthy food choice, and extracting resveratrol from them can add value to their potential health benefits.

3. Solvent Extraction

Once the plant source has been selected, the next step is solvent extraction. This is a commonly used method to isolate resveratrol from plant materials.

3.1 Ethanol as a Solvent

Ethanol is one of the most frequently used solvents for Resveratrol extraction. It has several advantages. Firstly, it is relatively safe to handle compared to some other organic solvents. Secondly, it can effectively dissolve resveratrol from plant tissues. In the process of extraction, the plant material (such as grape skins or peanut skins) is soaked in ethanol. This is known as maceration.

3.2 Maceration Process

During maceration, the plant material is left in the ethanol solvent for a certain period of time. This allows the resveratrol to dissolve into the ethanol. The duration of maceration can vary depending on factors such as the type of plant material, the particle size of the material, and the desired extraction efficiency. Generally, it can range from a few hours to several days. For example, in the case of grape skins, a maceration time of 24 - 48 hours may be sufficient to extract a significant amount of resveratrol.

4. Filtration

After the maceration process, the resulting mixture contains not only the dissolved resveratrol in ethanol but also solid impurities from the plant material. Filtration is then carried out to remove these solid impurities.

4.1 Types of Filters

There are different types of filters that can be used. Paper filters are commonly used for initial filtration, especially in small - scale extractions. They are relatively inexpensive and can effectively remove larger solid particles. For more precise filtration, membrane filters may be employed. These filters can remove smaller particles and can provide a cleaner filtrate.

4.2 Filtration Techniques

One common filtration technique is gravity filtration, where the mixture is poured through the filter under the influence of gravity. This is a simple and straightforward method, but it can be time - consuming. Another technique is vacuum filtration, which uses a vacuum pump to draw the mixture through the filter. This can speed up the filtration process significantly, especially when dealing with larger volumes of the extraction mixture.

5. Concentration

After filtration, the filtrate contains resveratrol dissolved in ethanol, but it is often in a relatively dilute form. Concentration under reduced pressure is then carried out to obtain a more concentrated form of the extract.

5.1 Rotary Evaporation

Rotary evaporation is a widely used method for concentrating the resveratrol - ethanol solution. In this process, the solution is placed in a rotary evaporator. The flask containing the solution is rotated while being heated gently under reduced pressure. The reduced pressure lowers the boiling point of the ethanol, allowing it to be evaporated more easily. As the ethanol evaporates, the concentration of resveratrol in the remaining solution increases.

5.2 Freeze - Drying

Another method for concentration is freeze - drying. In this process, the solution is first frozen, and then the water (if present) and ethanol are removed under vacuum. This method can be useful when the Resveratrol extract is sensitive to heat, as it avoids the use of high temperatures during concentration. However, it is a more complex and expensive process compared to rotary evaporation.

6. Purification

Although the concentrated extract obtained after concentration contains resveratrol, it may still contain other impurities. Purification steps are often necessary to obtain a high - purity resveratrol extract.

6.1 Chromatography Techniques

Chromatography is a powerful technique for purifying resveratrol. There are different types of chromatography that can be used, such as column chromatography and high - performance liquid chromatography (HPLC).

6.1.1 Column Chromatography

In column chromatography, a column is filled with a stationary phase (such as silica gel). The resveratrol - containing extract is then loaded onto the column. Different components in the extract will interact differently with the stationary phase and the mobile phase (usually a solvent). As the mobile phase is passed through the column, the components will elute at different times. Resveratrol can be collected separately based on its elution time, thus achieving purification.

6.1.2 High - Performance Liquid Chromatography (HPLC)

HPLC is a more advanced and precise chromatography technique. It uses a high - pressure pump to force the mobile phase through a column filled with a very fine stationary phase. This allows for better separation of components. In the case of resveratrol purification, HPLC can achieve a very high level of purity. However, it requires expensive equipment and skilled operators.

6.2 Recrystallization

Recrystallization is another purification method. In this process, the resveratrol extract is dissolved in a suitable solvent at a high temperature. Then, as the solution cools down, resveratrol will crystallize out, leaving behind impurities in the solution. The crystals can be collected and further processed to obtain a purer resveratrol product.

7. Conclusion

Extracting resveratrol extract from plants involves a series of steps, from selecting the right plant sources to purification. Each step is crucial in obtaining a high - quality, high - purity resveratrol extract. With the increasing interest in the health benefits of resveratrol, these extraction methods will continue to be refined and optimized to meet the demand for this valuable natural compound.

FAQ:

What are the common plant sources for resveratrol extraction?

Common plant sources for resveratrol extraction include grapes, peanuts and some berries.

What is the most commonly used solvent in the solvent extraction process of resveratrol?

Ethanol is a commonly used solvent in the solvent extraction process of resveratrol.

Why is filtration necessary in the resveratrol extraction process?

Filtration is necessary in the resveratrol extraction process to remove solid impurities.

What is the purpose of concentration under reduced pressure during resveratrol extraction?

The purpose of concentration under reduced pressure during resveratrol extraction is to obtain a more concentrated form of the extract.

Why are purification steps like chromatography techniques used in resveratrol extraction?

Purification steps like chromatography techniques are used in resveratrol extraction to get a high - purity white resveratrol extract.

Related literature

- Resveratrol: Sources, Bioavailability, and Potential Health Benefits"

- "Extraction and Analysis of Resveratrol from Natural Sources"

- "Optimization of Resveratrol Extraction from Plant Materials"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Lily extract

2024-12-01

-

Resveratrol extract

2024-12-01

-

Troxerutin

2024-12-01

-

Chasteberry Extract

2024-12-01

-

Mangosteen extract powder

2024-12-01

-

Motherwort Extract

2024-12-01

-

Camu Camu Extract

2024-12-01

-

Aminolevulinic acid

2024-12-01

-

Stevia Extract

2024-12-01

-

Chaste Berry Extract

2024-12-01