- 0086-571-85302990

- sales@greenskybio.com

How to make powder from Eucommia ulmoides extracts?

2024-11-30

1. Introduction to Eucommia Ulmoides Extract

Eucommia ulmoides is a well - known traditional Chinese medicinal plant. The extract of Eucommia ulmoides contains a variety of active components, such as flavonoids, lignans, polysaccharides, etc. These components are believed to have potential health - promoting effects, including anti - inflammatory, antioxidant, and blood - pressure - regulating functions. Making powder from its extract can not only preserve these beneficial components but also make it more convenient for various applications, such as in the pharmaceutical, food, and cosmetic industries.

2. Extraction of Active Components from Eucommia ulmoides

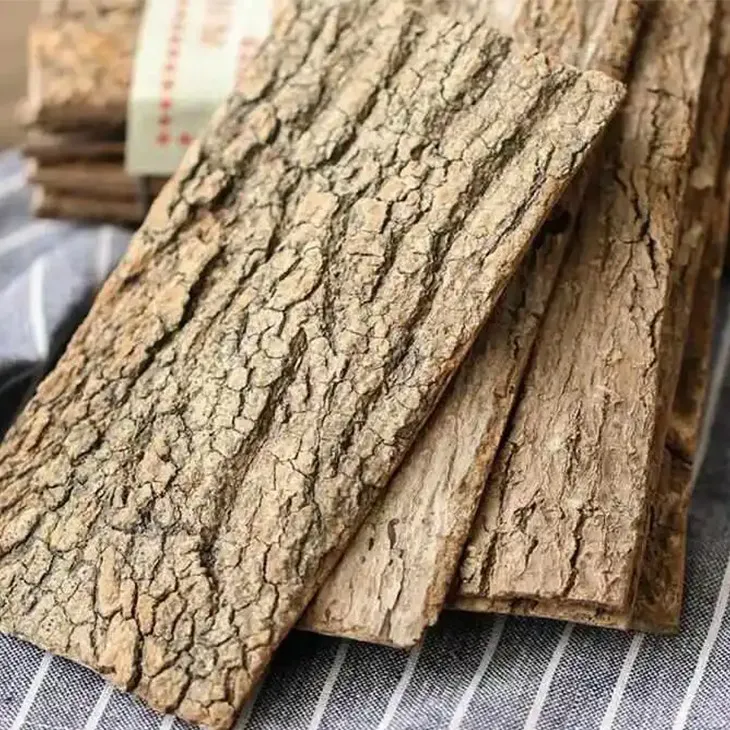

2.1 Selection of Raw Materials

High - quality Eucommia ulmoides bark or leaves are the basis for obtaining good extracts. The raw materials should be carefully selected, avoiding those with signs of pests, diseases, or contamination. Usually, the bark of Eucommia ulmoides is more commonly used for extraction due to its relatively high content of active ingredients.2.2 Solvent Extraction

Solvent extraction is a common method. Different solvents can be used according to the solubility of the target active components. For example, ethanol - water mixtures are often used. The ratio of ethanol to water needs to be optimized depending on the specific active components to be extracted. Generally, a higher ethanol content may be more suitable for extracting lipophilic components, while a lower ethanol content can extract more hydrophilic components.2.3 Supercritical Fluid Extraction

Supercritical fluid extraction, especially using carbon dioxide as the supercritical fluid, is also an option. This method has several advantages. It can operate at relatively low temperatures, which helps to preserve the activity of heat - sensitive components. Moreover, it is a relatively clean extraction method as no organic solvent residues are left. However, the equipment for supercritical fluid extraction is relatively expensive.

3. Concentration of the Extract

After extraction, the obtained extract usually contains a large amount of solvent, so concentration is necessary.

3.1 Evaporation

Evaporation under reduced pressure is a commonly used method. By reducing the pressure, the boiling point of the solvent can be lowered, which allows for efficient evaporation of the solvent at a relatively low temperature. This helps to prevent the degradation of active components due to overheating. During the evaporation process, appropriate temperature and pressure control are crucial.3.2 Reverse Osmosis

Reverse osmosis is another concentration method. It uses a semi - permeable membrane to separate the solvent from the extract. The pressure is applied to force the solvent to pass through the membrane, leaving behind a more concentrated extract. However, this method may be affected by factors such as membrane fouling, which requires regular maintenance of the membrane system.

4. Drying of the Concentrated Extract

4.1 Spray Drying

Spray drying is a popular method for converting the concentrated extract into powder. In this process, the concentrated extract is sprayed into a hot drying chamber in the form of fine droplets. The hot air in the chamber quickly evaporates the remaining moisture in the droplets, resulting in the formation of powder. The key parameters in spray drying include the inlet air temperature, outlet air temperature, and the atomization pressure. If the inlet air temperature is too high, it may cause the degradation of active components; if it is too low, the drying efficiency will be low.4.2 Freeze - Drying

Freeze - drying, also known as lyophilization, is another drying method. The concentrated extract is first frozen, and then the ice is directly sublimated under vacuum conditions. This method can better preserve the activity of the active components because it avoids the damage caused by high - temperature drying. However, freeze - drying is a relatively time - consuming and energy - consuming process, and the equipment cost is also relatively high.

5. Formation of Eucommia Ulmoides Extract Powder

After drying, the obtained product is the Eucommia Ulmoides Extract powder. However, in some cases, further processing may be required.

5.1 Grinding and Sieving

If the powder obtained from drying has large particles or agglomerates, grinding is necessary. Grinding can be carried out using a suitable grinder, such as a ball mill or a pulverizer. After grinding, sieving is carried out to obtain a powder with a uniform particle size. The appropriate particle size range depends on the specific application requirements, for example, for use in tablets, a relatively fine powder may be required.5.2 Blending and Formulation

In some applications, the Eucommia ulmoides extract powder may need to be blended with other ingredients. For example, in the food industry, it may be blended with sweeteners, flavors, or other functional ingredients to form a final product. In the pharmaceutical industry, it may be combined with excipients to prepare tablets, capsules, or other dosage forms.6. Safety and Efficacy Considerations

6.1 Safety

Although Eucommia ulmoides has a long history of use in traditional medicine, when making and using its extract powder, safety should still be a top priority. Quality control during the extraction, concentration, and drying processes is essential to ensure that there are no harmful substances, such as heavy metals or pesticide residues, in the final powder. In addition, appropriate safety evaluations, including toxicity tests, should be carried out, especially when the powder is intended for use in new products or for long - term use.6.2 Efficacy

The efficacy of Eucommia ulmoides extract powder depends on the integrity and activity of its active components. During the production process, any factors that may affect the activity of these components, such as high - temperature degradation or improper extraction methods, should be minimized. Moreover, scientific research is needed to further clarify the specific health - promoting effects of the powder and to establish appropriate dosage regimens for different applications.7. Conclusion

Making powder from Eucommia ulmoides extract involves a series of complex processes, from the extraction of active components to concentration, drying, and final powder formation. Each step requires careful consideration and control to ensure the quality, safety, and efficacy of the final product. With the increasing demand for natural products in various industries, the production of Eucommia ulmoides extract powder has great potential for development, but it also faces challenges in terms of quality control and scientific research.

FAQ:

Question 1: What are the main active components in Eucommia ulmoides extract?

The main active components in Eucommia ulmoides extract include aucubin, geniposidic acid, and various flavonoids. These components contribute to its potential health benefits such as antioxidant, anti - inflammatory, and hypotensive effects.

Question 2: How is the extraction of Eucommia ulmoides usually carried out?

Common extraction methods include solvent extraction. For example, using ethanol or water - ethanol mixtures to extract the active components from Eucommia ulmoides. This process aims to dissolve out the desired compounds from the plant material.

Question 3: What are the key steps in concentrating the Eucommia ulmoides extract?

One of the key steps in concentrating the extract is evaporation. This can be achieved through techniques like rotary evaporation. By reducing the solvent content, the concentration of the active components in the extract is increased.

Question 4: How is the drying process of the concentrated extract done?

Drying can be carried out through methods such as spray drying or freeze - drying. Spray drying involves spraying the concentrated extract into a hot air stream, while freeze - drying involves freezing the extract first and then removing the water by sublimation under reduced pressure. These methods help to obtain a dry product.

Question 5: How can the safety of the Eucommia ulmoides extract powder be ensured?

To ensure safety, strict quality control measures should be implemented throughout the production process. This includes sourcing high - quality Eucommia ulmoides raw materials, following good manufacturing practices during extraction, concentration, and drying. Also, proper testing for contaminants and heavy metals should be carried out.

Question 6: What are the potential efficacy applications of Eucommia ulmoides extract powder?

The potential efficacy applications include its use in traditional medicine for improving bone health, reducing blood pressure, and enhancing immune function. However, more research is still needed to fully understand and validate these effects.

Related literature

- Study on the Extraction and Bioactivity of Eucommia ulmoides Extracts"

- "Optimization of the Production Process of Eucommia ulmoides Extract Powder"

- "The Pharmacological Effects of Eucommia ulmoides Extract: A Review"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Extraction process of stevia extract.

2024-11-30

-

Chinese Grape Seed Extract Powder Factory.

2024-11-30

-

Vitamin K2 in China vs. the United States.

2024-11-30

-

Nature's Bounty L - Arginine

2024-11-30

-

Eucommia Ulmoides Extract

2024-11-30

-

Alisma Extract

2024-11-30

-

Diosmin

2024-11-30

-

Medicinal Marshmallow Extract

2024-11-30

-

Curcumin

2024-11-30

-

Artichoke Leaf Extract

2024-11-30

-

Cranberry Extract

2024-11-30

-

Natural grape seed extract

2024-11-30

-

Reishi mushroom extract

2024-11-30

-

Green Tea Extract

2024-11-30