- 0086-571-85302990

- sales@greenskybio.com

How to make powder with resveratrol extract?

2024-12-01

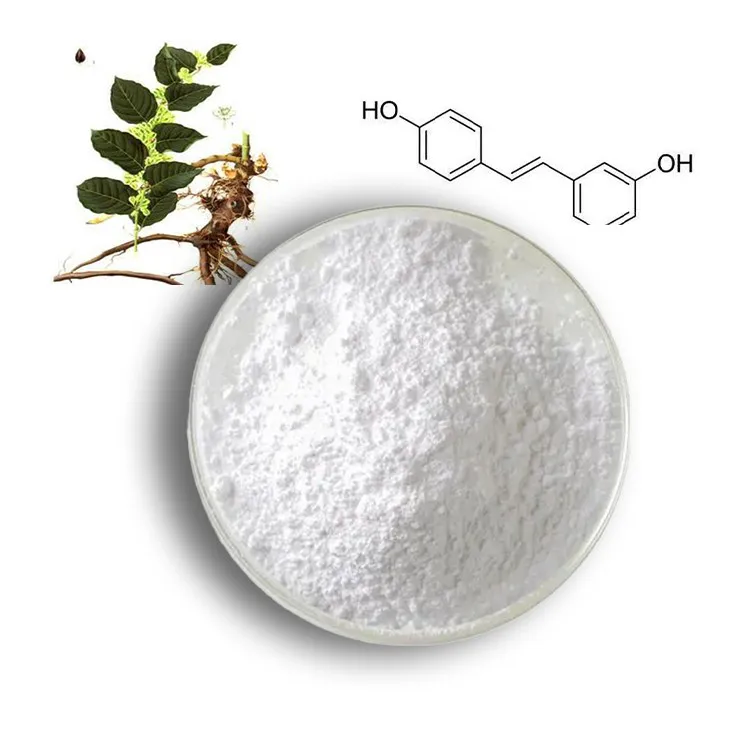

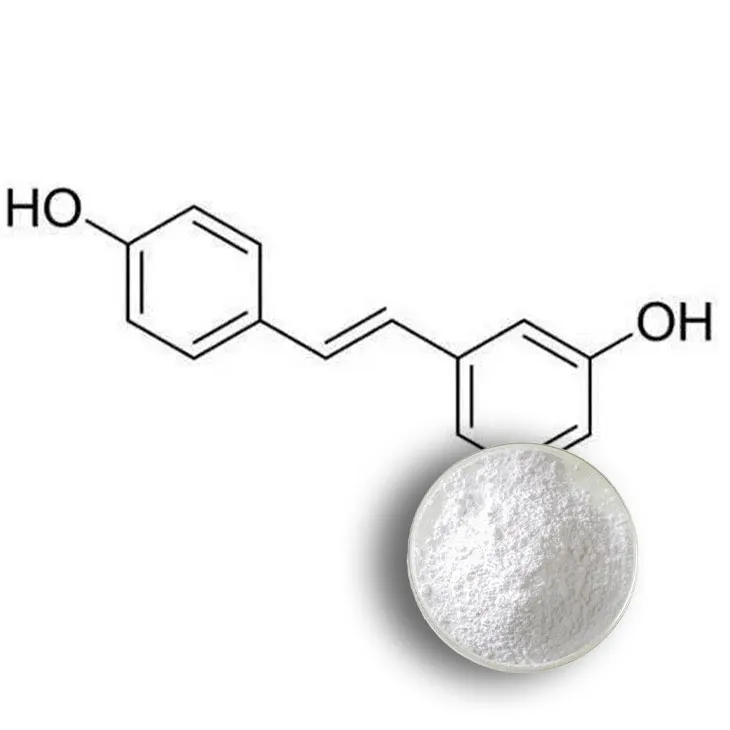

1. Introduction

Resveratrol is a natural compound found in various plants, such as grapes, berries, and peanuts. It has attracted significant attention in recent years due to its potential health benefits, including antioxidant, anti - inflammatory, and anti - cancer properties. Resveratrol extract can be further processed into powder form, which is more convenient for use in pharmaceuticals, nutraceuticals, and other applications. This article will explore the process of producing powder from Resveratrol extract in detail.

2. Equipment Needed

2.1 Extraction Equipment

Before making the powder, resveratrol needs to be extracted from the source material. Common extraction equipment includes Soxhlet extractors, which are useful for continuous extraction of compounds using solvents. Another option is supercritical fluid extraction (SFE) systems, especially those using carbon dioxide as the supercritical fluid. SFE is a preferred method as it is relatively clean and can produce high - quality Resveratrol extracts without leaving behind harmful solvent residues.

2.2 Drying Equipment

Once the resveratrol is extracted, drying is a crucial step to convert it into powder. Spray dryers are often used in the industry. Spray drying involves atomizing the liquid resveratrol extract into a fine mist and then drying it rapidly in a hot air stream. This results in the formation of fine powder particles. Freeze dryers can also be used. Freeze - drying, or lyophilization, involves freezing the extract and then removing the water by sublimation under vacuum. This method is particularly useful for heat - sensitive resveratrol extracts as it minimizes heat exposure and helps to preserve the integrity of the compound.

2.3 Grinding Equipment

If the dried resveratrol product is in the form of larger chunks or flakes, it may need to be ground into a fine powder. Ball mills are commonly used for this purpose. Ball mills work by rotating a cylinder containing balls, which crush and grind the material into a finer powder. Another option is a mortar and pestle, which is suitable for small - scale or laboratory - scale production. However, it may not be as efficient as a ball mill for large - scale production.

3. Production Process

3.1 Extraction

- Select the source material rich in resveratrol. For example, grape skins are a good source. The quality and quantity of resveratrol in the source material can significantly affect the final product.

- Prepare the extraction solvent. Depending on the extraction method, solvents such as ethanol or ethyl acetate may be used. The choice of solvent should be based on its ability to dissolve resveratrol effectively and its safety for subsequent use.

- Perform the extraction. If using a Soxhlet extractor, load the source material into the thimble and the solvent into the flask. Heat the solvent to reflux, and the solvent will continuously extract resveratrol from the source material. In the case of SFE, adjust the pressure and temperature of the supercritical carbon dioxide to optimize the extraction process.

- Collect the resveratrol - rich extract. After the extraction is complete, separate the extract from the source material. This can be done through filtration or other separation methods.

3.2 Drying

- If using spray drying, first adjust the concentration of the resveratrol extract. It should be in a suitable range to ensure proper atomization. Then, feed the extract into the spray dryer. Set the inlet and outlet air temperatures according to the properties of the extract. The inlet air temperature is usually in the range of 150 - 200°C, and the outlet air temperature is typically lower, around 80 - 100°C.

- For freeze - drying, place the resveratrol extract in the freeze - dryer. First, freeze the extract at a very low temperature, usually below - 40°C. Then, apply a vacuum to the chamber to initiate the sublimation process. This process can take a significant amount of time, depending on the quantity and nature of the extract.

3.3 Grinding (if necessary)

- If the dried resveratrol product is not in a fine powder form, transfer it to the grinding equipment. For a ball mill, load the material into the mill along with the grinding balls. Set the rotation speed and grinding time according to the desired particle size. Typically, a higher rotation speed and longer grinding time will result in a finer powder.

- If using a mortar and pestle, place the dried material in the mortar and gently grind it with the pestle. This method requires more manual effort but can be useful for small - scale production or for obtaining a more controlled powder texture.

4. Quality Control

4.1 Purity Analysis

It is essential to analyze the purity of the resveratrol powder. High - performance liquid chromatography (HPLC) is a commonly used method. HPLC can accurately separate and quantify resveratrol in the powder sample. The purity of the resveratrol powder should meet the requirements for its intended use, whether it is for pharmaceuticals or nutraceuticals. For pharmaceutical - grade resveratrol powder, a higher purity level is usually required compared to nutraceutical - grade powder.

4.2 Particle Size Analysis

The particle size of the resveratrol powder can affect its solubility, bioavailability, and handling properties. Laser diffraction particle size analyzers are often used to measure the particle size distribution of the powder. The ideal particle size may vary depending on the application. For example, in a formulation where rapid dissolution is required, a smaller particle size may be preferred.

4.3 Residual Solvent Analysis

If solvents were used during the extraction process, it is crucial to check for residual solvents in the final powder. Gas chromatography (GC) is a reliable method for detecting and quantifying residual solvents. Residual solvents should be within the acceptable limits set by regulatory agencies to ensure the safety of the product.

5. Safety Precautions

5.1 Chemical Handling

During the extraction process, when handling solvents such as ethanol or ethyl acetate, proper safety measures must be taken. These solvents are flammable, so there should be no open flames or potential ignition sources in the work area. Workers should wear appropriate protective clothing, including gloves and safety glasses. In addition, proper ventilation is essential to prevent the build - up of solvent vapors, which can be harmful if inhaled.

5.2 Equipment Operation

When operating extraction, drying, and grinding equipment, it is important to follow the manufacturer's instructions carefully. For example, in a spray dryer, incorrect setting of the air temperatures can lead to product degradation or equipment malfunction. Regular maintenance of the equipment is also necessary to ensure its safe and efficient operation. This includes cleaning, lubrication, and inspection of parts for wear and tear.

5.3 Hygiene and Contamination Control

The production area should be kept clean and free from contaminants. Workers should follow good manufacturing practices (GMP) to prevent cross - contamination. This includes proper hand - washing, wearing clean work clothes, and using dedicated tools for different production steps. Any raw materials or intermediate products should be stored properly to avoid contamination by dust, moisture, or other substances.

6. Properties of Resveratrol Extract Powder

6.1 Antioxidant Properties

Resveratrol powder retains the antioxidant properties of the resveratrol compound. Antioxidants are substances that can neutralize free radicals in the body, which are unstable molecules that can cause damage to cells and tissues. The antioxidant activity of resveratrol powder makes it a valuable ingredient in nutraceuticals and skincare products, as it can help to protect the body from oxidative stress and slow down the aging process.

6.2 Solubility

The solubility of resveratrol powder can vary depending on factors such as particle size and the presence of other substances. In general, finer particles tend to have better solubility. However, resveratrol is a relatively hydrophobic compound, so it may require the use of appropriate solvents or formulation techniques to improve its solubility in aqueous solutions. This is important for its application in pharmaceuticals and nutraceuticals, where solubility can affect bioavailability.

6.3 Stability

Resveratrol powder can be affected by environmental factors such as light, heat, and moisture. To maintain its stability, it is often stored in a cool, dry place, preferably in a sealed container. In some cases, additives may be used to improve the stability of the powder. For example, antioxidants can be added to prevent oxidation of the resveratrol during storage.

7. Applications in Pharmaceuticals and Nutraceuticals

7.1 Pharmaceuticals

Resveratrol powder has potential applications in the pharmaceutical industry. Its anti - inflammatory and anti - cancer properties are being explored for the development of new drugs. For example, it may be used in the formulation of drugs for treating chronic inflammatory diseases or as an adjuvant in cancer therapy. However, further research is needed to fully understand its pharmacological mechanisms and to develop effective drug formulations.

7.2 Nutraceuticals

In the nutraceutical field, resveratrol powder is a popular ingredient. It can be added to dietary supplements, functional foods, and beverages. Consumers are increasingly interested in products containing resveratrol due to its potential health benefits, such as improving cardiovascular health, enhancing immunity, and reducing the risk of age - related diseases. The powder form makes it easy to incorporate into various product formulations.

8. Conclusion

Producing powder from resveratrol extract involves several steps, including extraction, drying, and optionally grinding. Appropriate equipment and strict safety precautions are necessary throughout the process. Quality control measures are crucial to ensure the purity, particle size, and absence of residual solvents in the final product. The resulting resveratrol extract powder has unique properties that make it suitable for applications in pharmaceuticals and nutraceuticals. As research on resveratrol continues, its potential applications are likely to expand further.

FAQ:

What equipment is required to make powder from resveratrol extract?

Typically, you would need equipment such as a drying apparatus (like a spray dryer or freeze dryer), a grinder to ensure a fine powder consistency if the dried product is not already in a powdered form, and proper mixing equipment to ensure homogeneity if any additional substances are being added. Also, containers for storing the resveratrol extract powder are necessary, which should be airtight and light - resistant to protect the powder from degradation.

What are the main safety precautions during the production of resveratrol extract powder?

When producing resveratrol extract powder, safety is crucial. First, proper ventilation is required as resveratrol or its extraction solvents may be volatile or have fumes. Workers should wear appropriate personal protective equipment (PPE), including gloves, goggles, and lab coats. Since resveratrol is a chemical compound, avoid contact with skin and eyes. In case of handling any flammable solvents during extraction, fire safety measures such as keeping away from open flames and having fire extinguishers nearby are essential. Also, ensure that the production area is clean and free from contaminants to maintain the purity of the resveratrol extract powder.

What are the unique properties of resveratrol extract powder?

Resveratrol extract powder has several unique properties. It is a polyphenol with antioxidant properties, which means it can scavenge free radicals in the body, potentially reducing oxidative stress. It has anti - inflammatory effects, which may be beneficial in various health conditions. In pharmaceuticals, it may have potential in drug development for diseases related to oxidative stress and inflammation. In nutraceuticals, it can be added to supplements for its health - promoting properties. Additionally, it has relatively good stability when stored properly, which allows for its use in various product formulations.

How can the quality of resveratrol extract powder be ensured?

To ensure the quality of resveratrol extract powder, several steps can be taken. Firstly, start with high - quality resveratrol extract. This requires using reliable sources for the raw material and proper extraction methods. During the powder - making process, strict control of process parameters such as temperature, pressure (in drying processes), and mixing time is essential. Regular testing for purity, including the absence of contaminants and accurate resveratrol content, should be carried out. Analytical techniques like HPLC (High - Performance Liquid Chromatography) can be used to measure the resveratrol concentration. Packaging also plays a role in maintaining quality; using proper packaging materials to prevent moisture absorption, oxidation, and light - induced degradation.

Can resveratrol extract powder be used directly in pharmaceuticals?

Resveratrol extract powder may not be used directly in pharmaceuticals in all cases. While it has potential pharmaceutical applications due to its properties like antioxidant and anti - inflammatory effects, it often needs to undergo further processing and formulation. It may need to be combined with other substances to enhance its bioavailability, stability, and effectiveness. Additionally, strict regulatory requirements must be met before it can be incorporated into pharmaceutical products. These requirements include demonstrating safety, efficacy, and quality control through pre - clinical and clinical trials.

Related literature

- Resveratrol: Sources, Properties, and Applications in Health and Disease"

- "The Production and Characterization of Resveratrol - Based Compounds for Therapeutic Use"

- "Advances in Resveratrol Extraction and Powder Formulation for Nutraceutical Applications"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Mulberry leaf Extract

2024-12-01

-

Lemon Juice Powder

2024-12-01

-

Diosmin

2024-12-01

-

Plantain extract

2024-12-01

-

Bayberry Extract

2024-12-01

-

Green Tea Extract

2024-12-01

-

melatonin extract

2024-12-01

-

Chia Seed Powder

2024-12-01

-

Sea buckthorn Juice Powder

2024-12-01

-

Peppermint Oil

2024-12-01