- 0086-571-85302990

- sales@greenskybio.com

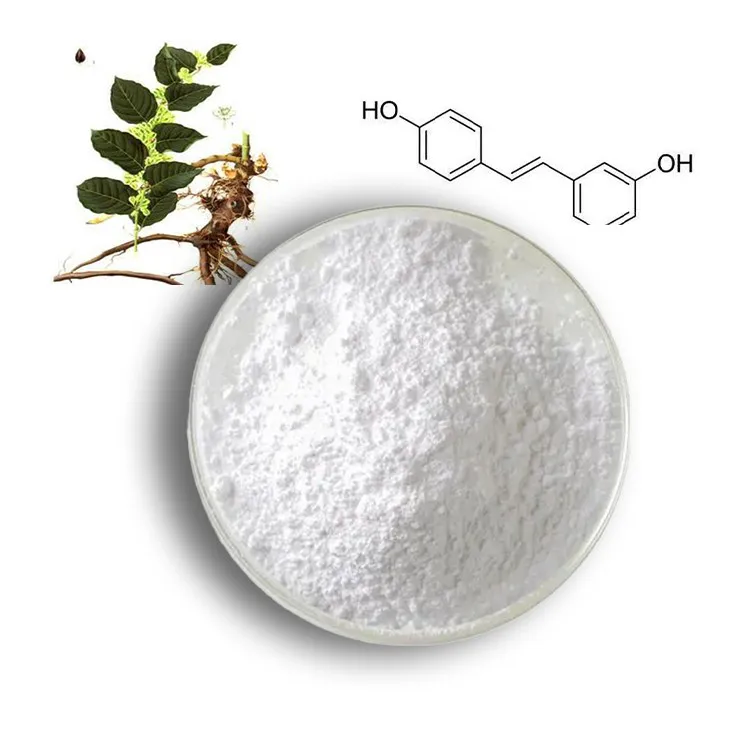

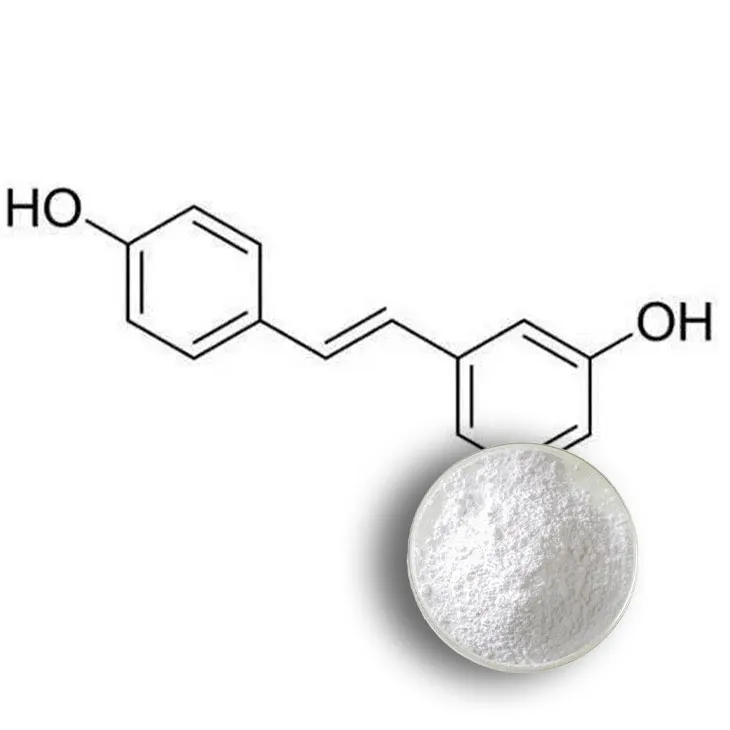

Manufacturer of Organic Resveratrol Extract Powder.

2024-11-28

Introduction

In the realm of health - enhancing substances, organic Resveratrol extract powder has emerged as a star product. This compound has attracted significant attention due to its potential health benefits, which range from antioxidant properties to possible anti - aging effects. Manufacturers of this remarkable powder play a crucial role in bringing its benefits to the global market.

The Importance of Raw Material Selection

These manufacturers are often at the forefront of innovation, and it all begins with the careful selection of high - quality raw materials. Organic grapes, for instance, are a prime source of resveratrol. The quality of the grapes directly impacts the quality of the final extract powder.

- Organic Certification: Manufacturers need to ensure that the grapes are organically grown. This means that they are free from pesticides, herbicides, and other synthetic chemicals. Organic certification provides consumers with the assurance that the product is pure and natural.

- Varietal Selection: Different grape varieties contain varying levels of resveratrol. Some varieties are known to have higher concentrations, and manufacturers may choose these specific varieties to obtain a more potent extract. For example, red grapes, especially those from certain regions, are often preferred for their higher resveratrol content.

- Harvesting Conditions: The time of harvest and the conditions under which the grapes are harvested also matter. Grapes harvested at the right maturity level are likely to have a higher resveratrol content. Additionally, factors such as climate and soil quality can influence the resveratrol levels in the grapes.

The Complex Extraction Process

The extraction process of resveratrol from grapes is a complex and meticulous one. Advanced techniques are employed to ensure the purity and potency of the Resveratrol extract powder.

- Pre - treatment of Grapes: Before extraction, the grapes are typically washed and sorted. Any damaged or unripe grapes are removed. This step is important to ensure that only high - quality grapes are used for extraction.

- Extraction Methods: There are several methods for extracting resveratrol from grapes. One common method is solvent extraction, where solvents such as ethanol or methanol are used to dissolve the resveratrol from the grape skins and seeds. Another method is supercritical fluid extraction, which uses supercritical carbon dioxide. This method is often preferred as it is more environmentally friendly and can produce a purer extract.

- Purification and Concentration: After extraction, the resulting solution contains not only resveratrol but also other compounds. The extract is then purified to remove impurities. This may involve processes such as filtration, chromatography, or distillation. The purified extract is then concentrated to increase the resveratrol content, resulting in the final Resveratrol extract powder.

Quality Control: A Non - Negotiable Aspect

Quality control is non - negotiable for these manufacturers. Stringent tests are carried out at every stage of production. This includes checks for contaminants, accurate measurement of resveratrol content, and ensuring compliance with international quality standards such as Good Manufacturing Practice (GMP).

- Contaminant Testing: Manufacturers test for various contaminants, including heavy metals, pesticides (even in the case of organic products to ensure no cross - contamination), and microbial contaminants. This is crucial to ensure the safety of the product for human consumption.

- Resveratrol Content Analysis: Accurate measurement of resveratrol content is essential. High - performance liquid chromatography (HPLC) is often used to determine the exact amount of resveratrol in the extract powder. This ensures that the product meets the labeled claims.

- GMP Compliance: Adhering to Good Manufacturing Practice standards ensures that the manufacturing process is carried out in a controlled and hygienic environment. This includes aspects such as proper handling of raw materials, clean production facilities, and trained personnel.

Research and Development: Unlocking New Potential

Moreover, many manufacturers are also involved in research and development. They strive to discover new applications and enhance the bioavailability of the resveratrol extract. This could involve formulating it in different ways, such as encapsulation, to improve its absorption in the human body.

- New Applications: Research is being conducted to explore the potential of resveratrol in treating various diseases. Some studies suggest that it may have anti - cancer properties, while others are looking into its role in cardiovascular health. Manufacturers are interested in these findings as they could lead to new product lines or expanded uses for their resveratrol extract powder.

- Bioavailability Enhancement: One of the challenges with resveratrol is its relatively low bioavailability. To overcome this, manufacturers are exploring different formulation techniques. Encapsulation, for example, can protect the resveratrol from degradation in the digestive system and improve its absorption. Other techniques such as nano - formulation are also being investigated.

Sustainable Practices: A Growing Concern

In addition, sustainable practices are becoming increasingly important for these manufacturers. They are aware of the environmental impact of their operations and are taking steps to reduce waste, conserve energy, and promote sustainable sourcing of raw materials.

- Waste Reduction: Manufacturers are implementing measures to reduce waste generated during the production process. This may include recycling of packaging materials, reusing by - products of the extraction process, or optimizing production processes to minimize waste.

- Energy Conservation: Energy - intensive processes such as extraction and purification are being optimized to reduce energy consumption. This may involve using more energy - efficient equipment or adjusting production schedules to take advantage of off - peak energy rates.

- Sustainable Sourcing: As mentioned earlier, sustainable sourcing of raw materials, such as organic grapes, is crucial. Manufacturers are working with farmers to promote sustainable farming practices, such as water conservation, soil protection, and biodiversity preservation.

Conclusion

Overall, organic resveratrol extract powder manufacturers are key players in the pursuit of better health and a more sustainable future. Through their careful selection of raw materials, complex extraction processes, strict quality control, research and development efforts, and commitment to sustainable practices, they are bringing a valuable product to the market. As the demand for health - enhancing products continues to grow, these manufacturers will play an even more important role in providing high - quality organic resveratrol extract powder to consumers around the world.

FAQ:

What are the main sources of raw materials for organic resveratrol extract powder?

The main source of raw materials for organic resveratrol extract powder is often organic grapes. Manufacturers carefully select high - quality organic grapes as the starting point for production.

How do manufacturers ensure the purity of organic resveratrol extract powder?

Manufacturers ensure the purity of organic resveratrol extract powder through a complex and meticulous extraction process. They employ advanced techniques during the extraction. Also, stringent quality control measures are in place. At every stage of production, tests are carried out for contaminants, and accurate measurement of resveratrol content is made to ensure its purity.

What role does quality control play in the production of organic resveratrol extract powder?

Quality control is of utmost importance in the production of organic resveratrol extract powder. It is non - negotiable. Stringent tests are carried out at every production stage, including checks for contaminants, accurate measurement of resveratrol content, and ensuring compliance with international quality standards such as Good Manufacturing Practice (GMP).

Why are manufacturers involved in research and development related to resveratrol extract?

Manufacturers are involved in research and development related to resveratrol extract to discover new applications and enhance its bioavailability. For example, they may formulate it in different ways, like encapsulation, to improve its absorption in the human body.

How are manufacturers promoting sustainable practices in the production of organic resveratrol extract powder?

Manufacturers are promoting sustainable practices in the production of organic resveratrol extract powder by being aware of the environmental impact of their operations. They are taking steps to reduce waste, conserve energy, and promote sustainable sourcing of raw materials.

Related literature

- Organic Resveratrol: Production and Health Benefits"

- "The Role of Manufacturers in the Quality Assurance of Resveratrol Extracts"

- "Sustainable Production of Organic Resveratrol - Extract Powder: A Review"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

Active ingredient of shikonin.

2024-11-28

-

Chinese lotus leaf extract suppliers.

2024-11-28

-

Nature's Bounty Tongkat Ali Extract Powder.

2024-11-28

-

Nature's Bounty lotus leaf extract.

2024-11-28

-

Organic Almond Extract Powder Supplier.

2024-11-28

-

Dan Shen Root Extract/Salvia Root Extract

2024-11-28

-

Hesperidin

2024-11-28

-

White Willow Bark Extract

2024-11-28

-

Wheat Germ Extract

2024-11-28

-

Grape Seed Extract

2024-11-28

-

Green coffee bean Extract

2024-11-28

-

Bitter Melon Extract

2024-11-28

-

Peppermint Extract Powder

2024-11-28

-

Curcumin

2024-11-28

-

Chaste Berry Extract

2024-11-28