- 0086-571-85302990

- sales@greenskybio.com

Manufacturers of Organic Astaxanthin Powder.

2024-11-28

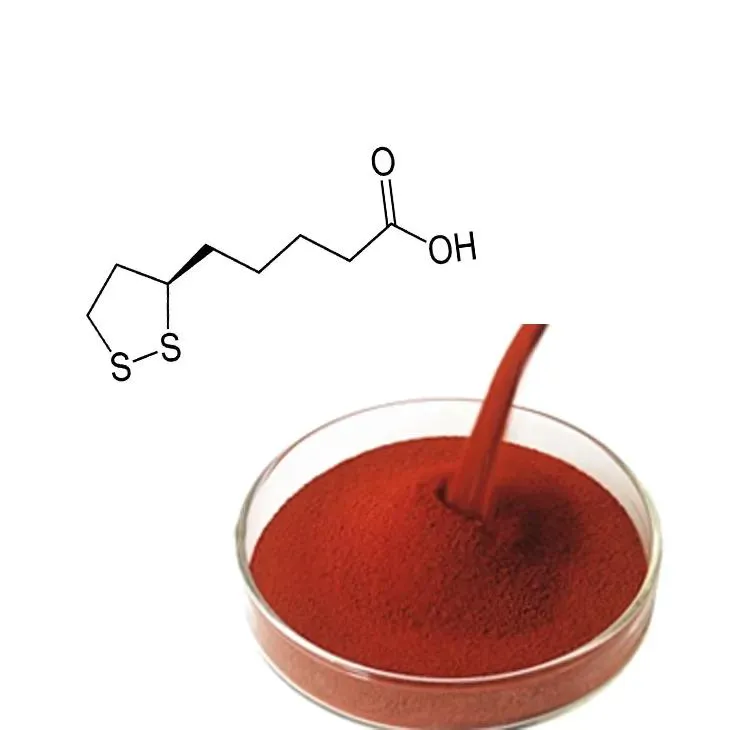

1. Introduction to Organic Astaxanthin Powder

Organic Astaxanthin powder has gained significant popularity in recent years in the field of natural supplements. Astaxanthin is a powerful antioxidant, known for its numerous health benefits. It is a carotenoid pigment, which gives certain organisms their characteristic red color. In nature, it can be found in various sources, but when it comes to commercial production, manufacturers often focus on specific organisms for extraction.

2. The Role of Manufacturers in the Production Chain

Manufacturers play a crucial role in the entire lifecycle of organic astaxanthin powder. They are responsible for ensuring that the final product is of high quality, safe for consumption, and meets all the necessary regulatory requirements.

2.1 Cultivation of Astaxanthin - Producing Organisms

One of the initial steps for manufacturers is the cultivation of organisms that produce astaxanthin. Microalgae, such as Haematococcus pluvialis, are a popular choice. These microalgae have the ability to synthesize astaxanthin under certain environmental conditions.

- Manufacturers need to create optimal growth conditions for these microalgae.

- They must control factors like light intensity, temperature, and nutrient availability.

- For example, a proper balance of nitrogen and phosphorus in the growth medium is essential for the healthy growth of Haematococcus pluvialis and subsequent astaxanthin production.

2.2 Extraction Process

Once the microalgae have synthesized astaxanthin, the extraction process begins.

- First, the microalgae are harvested. This can be done through various methods such as centrifugation or filtration.

- After harvesting, the cells need to be broken open to release the astaxanthin. Mechanical methods like high - pressure homogenization or chemical methods may be used. However, manufacturers need to ensure that these methods do not degrade the astaxanthin or introduce contaminants.

- The extracted astaxanthin then needs to be separated from other cellular components. This can be a complex process involving chromatography or solvent extraction techniques.

2.3 Conversion into Powder Form

After extraction, the astaxanthin is usually in a liquid or semi - liquid form. To make it more stable and convenient for use in supplements, it is converted into powder form.

- Manufacturers may use techniques such as spray - drying or freeze - drying.

- During spray - drying, the liquid astaxanthin is sprayed into a hot chamber where the solvent evaporates, leaving behind a powder. In freeze - drying, the astaxanthin is frozen and then the water is removed under vacuum conditions.

3. Ensuring Quality and Safety

Quality and safety are of utmost importance for manufacturers of organic astaxanthin powder.

3.1 Contaminant Control

Contaminant control is a key aspect.

- Manufacturers need to ensure that the microalgae cultures are free from harmful bacteria, viruses, and other microorganisms.

- During the extraction and processing steps, they must prevent the introduction of chemical contaminants such as solvents residues or heavy metals.

- Regular testing of the raw materials, intermediate products, and final products is essential to detect and eliminate any potential contaminants.

3.2 Adherence to Organic Regulations

Since it is an organic product, manufacturers must adhere to strict organic regulations.

- They need to source their raw materials from organic - certified suppliers.

- The production process should be free from synthetic pesticides, fertilizers, and genetically modified organisms.

- Organic certification bodies regularly audit the manufacturing facilities to ensure compliance.

4. Improving Production Efficiency

In addition to quality control, manufacturers are constantly striving to improve production efficiency.

4.1 Technological Advancements

Technological advancements play a significant role.

- New cultivation techniques are being developed to increase the yield of astaxanthin - producing microalgae. For example, the use of photobioreactors can provide more controlled and efficient growth conditions compared to traditional open - pond systems.

- Improved extraction methods are also being explored. These can reduce the cost and time required for extraction while maintaining the quality of astaxanthin.

4.2 Process Optimization

Manufacturers are looking at ways to optimize the entire production process.

- They are analyzing each step of the process to identify bottlenecks and areas for improvement.

- For example, in the cultivation step, they may optimize the nutrient dosing schedule to maximize growth. In the extraction process, they may streamline the separation steps to reduce waste and increase efficiency.

5. Contribution to the Market

The manufacturers of organic astaxanthin powder contribute significantly to the expanding market.

5.1 Meeting Growing Demand

As the awareness of the health benefits of astaxanthin grows, the demand for organic astaxanthin powder is increasing. Manufacturers are able to meet this demand through their production capabilities.

- They are scaling up their production processes to supply the market with sufficient quantities of the product.

- By ensuring a stable supply, they help to maintain the growth of the market for organic astaxanthin powder.

5.2 Product Innovation

Manufacturers are also driving product innovation.

- They are developing new formulations of astaxanthin powder, such as encapsulated forms for better bioavailability.

- Some are exploring combinations of astaxanthin with other beneficial nutrients to create more comprehensive supplements.

5.3 Market Education

Another important contribution is market education.

- Manufacturers are involved in promoting the health benefits of astaxanthin through various channels.

- They provide information to consumers, healthcare professionals, and retailers about the proper use and potential benefits of organic astaxanthin powder.

6. Challenges Faced by Manufacturers

Despite their important role, manufacturers of organic astaxanthin powder face several challenges.

6.1 High Production Costs

The production of organic astaxanthin powder can be costly.

- Cultivating astaxanthin - producing organisms requires significant investment in terms of equipment, energy, and raw materials.

- The extraction and conversion processes also involve high costs, especially when maintaining high quality and adhering to organic regulations.

6.2 Competition

The market for natural supplements is highly competitive.

- There are many manufacturers of astaxanthin powder, both organic and non - organic.

- Manufacturers need to constantly differentiate their products through quality, innovation, and marketing to stay competitive.

6.3 Regulatory Compliance

As mentioned earlier, strict regulatory compliance is required.

- Keeping up with the ever - changing organic regulations can be a challenge for manufacturers.

- Any non - compliance can lead to serious consequences, including product recalls and damage to the company's reputation.

7. Conclusion

Manufacturers of organic astaxanthin powder are at the heart of the production and supply of this valuable natural supplement. Their role in cultivating the source organisms, extracting and converting astaxanthin into powder form, ensuring quality and safety, and contributing to the market is of great significance. Despite the challenges they face, they continue to drive the growth and development of the organic astaxanthin powder market. As research on astaxanthin continues to uncover more of its potential health benefits, the role of these manufacturers will become even more crucial in meeting the increasing demand and providing high - quality products to consumers.

FAQ:

What are the main sources for manufacturing organic astaxanthin powder?

The main source for manufacturing organic astaxanthin powder is certain types of algae. These algae are cultivated by manufacturers as they are natural producers of astaxanthin. Through a series of processes, the astaxanthin from these algae can be extracted and converted into powder form.

How do manufacturers ensure the quality of organic astaxanthin powder?

Manufacturers ensure the quality of organic astaxanthin powder in multiple ways. Firstly, they start with careful cultivation of the source organisms to ensure optimal astaxanthin production. During the extraction process, they use advanced techniques to avoid any degradation of the compound. They also conduct strict quality control tests to check for contaminants and ensure that the product adheres to strict organic regulations. Finally, proper storage and packaging are carried out to maintain the integrity of the powder.

What challenges do manufacturers of organic astaxanthin powder face?

Manufacturers of organic astaxanthin powder face several challenges. One major challenge is maintaining the purity of the product during the extraction and conversion processes. Since it has to be free from contaminants, any impurity in the source or during processing can be a problem. Another challenge is the cost - efficient production. Improving production efficiency while still meeting high - quality standards can be difficult. Also, competition in the market means they need to constantly innovate to stay ahead.

How do manufacturers contribute to the expanding market of organic astaxanthin powder?

Manufacturers contribute to the expanding market of organic astaxanthin powder in various ways. They ensure a consistent supply of high - quality products, which builds trust among consumers. By constantly improving production techniques, they can reduce costs and make the product more accessible. They also invest in research to discover new benefits of astaxanthin, which can drive more demand. Their compliance with organic regulations also gives consumers confidence in the product's quality and safety.

What role does research play in the manufacturing of organic astaxanthin powder?

Research plays a very important role in the manufacturing of organic astaxanthin powder. It helps manufacturers to find better ways of cultivating the source organisms for higher astaxanthin yields. Research also aids in developing more efficient extraction and conversion methods. It can lead to the discovery of new applications for astaxanthin, which in turn can expand the market. Additionally, research helps in understanding how to maintain the stability and quality of the powder during storage and transportation.

Related literature

- Organic Astaxanthin Production: Current Trends and Future Prospects"

- "The Role of Manufacturers in the Quality Assurance of Organic Astaxanthin Powder"

- "Advances in the Cultivation of Astaxanthin - Producing Organisms for Powder Manufacturing"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Astaxanthin

2024-11-28

-

Grapefruit Seed Extract Powder

2024-11-28

-

Ivy Extract

2024-11-28

-

Camu Camu Extract

2024-11-28

-

Soy Extract

2024-11-28

-

Yam Extract

2024-11-28

-

Oat Straw Extract Powder

2024-11-28

-

Passionflower Extract

2024-11-28

-

Alisma Extract

2024-11-28

-

Grape Seed Extract

2024-11-28