- 0086-571-85302990

- sales@greenskybio.com

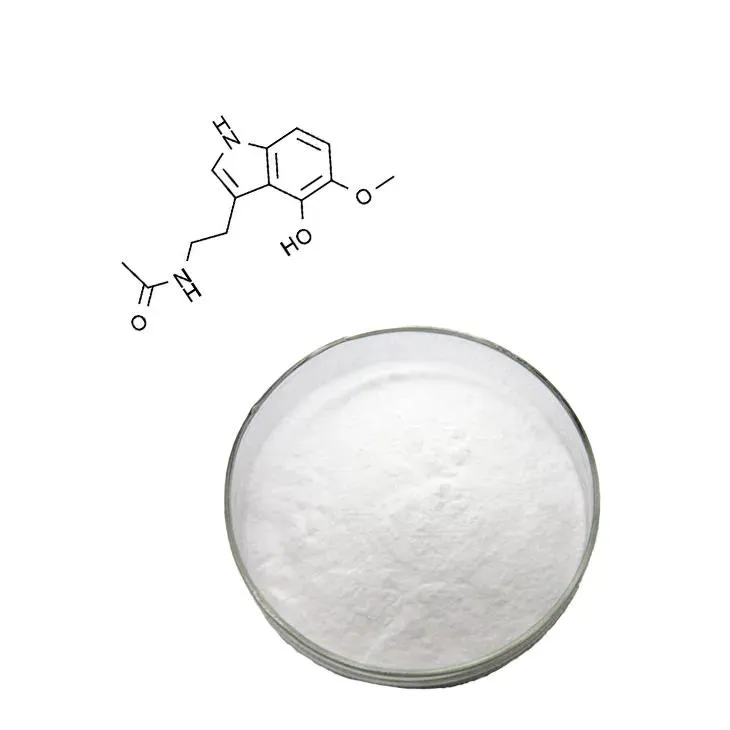

Melatonin extraction technology and production process.

2024-11-29

1. Introduction: The Significance of Melatonin

Melatonin, a hormone mainly secreted by the pineal gland in the brain, plays a crucial role in various physiological functions. It is often referred to as the "hormone of darkness" as its production is typically stimulated by darkness and inhibited by light.

Regulation of Circadian Rhythms: One of the most important functions of melatonin is its role in regulating the body's circadian rhythms. It helps to synchronize the internal body clock with the external day - night cycle. This is essential for a proper sleep - wake cycle, as it signals the body when it is time to sleep and when it is time to wake up. For example, people who experience jet lag often have disrupted melatonin secretion, which can lead to sleep disturbances until the body's internal clock is realigned.

Antioxidant Properties: Melatonin also exhibits strong antioxidant properties. It can scavenge free radicals, which are highly reactive molecules that can cause damage to cells, DNA, and proteins. By neutralizing these free radicals, melatonin helps to protect the body from oxidative stress - related diseases such as neurodegenerative disorders (e.g., Alzheimer's and Parkinson's diseases), cardiovascular diseases, and certain types of cancer.

Immune System Modulation: There is evidence to suggest that melatonin can modulate the immune system. It can enhance the function of immune cells such as lymphocytes and macrophages, helping the body to better defend against pathogens. During times of stress or illness, the body's melatonin levels may change, and this may be part of the body's adaptive response to boost immunity.

2. melatonin extraction Techniques

2.1 Solvent Extraction

Principle: Solvent extraction is one of the most commonly used methods for melatonin extraction. It is based on the principle that melatonin is soluble in certain organic solvents. The process involves grinding the source material (such as pineal glands from animals or plant tissues that may contain melatonin - like substances) into a fine powder. Then, an appropriate organic solvent, such as ethyl acetate or chloroform, is added to the powder.

Advantages:

- High extraction efficiency: It can effectively extract melatonin from the source material, especially when the proper solvent and extraction conditions are selected.

- Well - established method: It has been widely studied and used in the industry, and there are relatively mature extraction protocols available.

Limitations:

- Solvent toxicity: Many of the organic solvents used in this method are toxic, which poses a potential risk to the environment and human health. Special safety precautions need to be taken during the extraction process.

- Selectivity issues: The method may not be highly selective, and other substances in the source material may also be co - extracted along with melatonin, requiring further purification steps.

2.2 Supercritical Fluid Extraction (SFE)

Principle: Supercritical fluid extraction utilizes supercritical fluids, typically carbon dioxide (CO₂) in its supercritical state. In the supercritical state, CO₂ has properties between those of a gas and a liquid, such as high diffusivity and low viscosity. The supercritical CO₂ can penetrate into the source material and selectively extract melatonin based on its solubility in the supercritical fluid.

Advantages:

- Environmentally friendly: Since CO₂ is non - toxic, non - flammable, and easily available, it is a more environmentally friendly solvent compared to traditional organic solvents used in solvent extraction.

- High selectivity: Supercritical CO₂ can often selectively extract melatonin, leaving behind many of the unwanted impurities in the source material, reducing the need for extensive purification steps.

Limitations:

- High - cost equipment: The equipment required for supercritical fluid extraction is relatively expensive, which may limit its widespread use, especially in small - scale operations.

- Complex operation: The process requires precise control of pressure, temperature, and flow rate to maintain the supercritical state of CO₂, and any deviation may affect the extraction efficiency.

2.3 Solid - Phase Extraction (SPE)

Principle: Solid - phase extraction involves passing the sample solution through a solid - phase sorbent cartridge. The melatonin in the sample selectively binds to the sorbent material in the cartridge, while other components in the solution pass through. Subsequently, the melatonin can be eluted from the cartridge using an appropriate elution solvent.

Advantages:

- Good purification ability: It can effectively remove impurities from the sample, resulting in a relatively pure melatonin extract.

- Versatility: Different types of sorbent materials can be used depending on the nature of the sample and the extraction requirements, allowing for flexibility in the extraction process.

Limitations:

- Low sample capacity: The amount of sample that can be processed at one time is relatively limited, which may not be suitable for large - scale production without proper scale - up.

- Sorbent cost: Some high - performance sorbent materials can be expensive, increasing the overall cost of the extraction process.

3. Melatonin Production Process

3.1 Raw Material Selection

Animal - Based Sources: Traditionally, pineal glands from animals such as cows and sheep have been used as a source of melatonin. However, with increasing concerns about animal welfare and potential zoonotic diseases, the use of animal - derived melatonin has become more restricted in some regions.

Plant - Based Sources: Many plants contain melatonin - like substances or precursors. For example, some fruits (such as cherries), nuts, and grains have been found to contain melatonin. Plant - based sources are becoming more popular as they are more sustainable and less likely to cause ethical or health concerns related to animal products.

3.2 Initial Extraction

Pre - treatment of Raw Materials: Before extraction, the raw materials need to be pre - treated. For plant - based materials, this may involve washing, drying, and grinding to increase the surface area for extraction. For animal - based materials, proper handling and sterilization procedures are necessary.

Extraction Method Selection: Depending on the type of raw material and the desired purity of the final product, one of the extraction techniques mentioned above (solvent extraction, supercritical fluid extraction, or solid - phase extraction) is selected. The extraction process is carried out under carefully controlled conditions, such as temperature, pressure (in the case of supercritical fluid extraction), and solvent - to - sample ratio.

3.3 Purification

Chromatographic Purification: After the initial extraction, the melatonin extract often contains impurities. Chromatographic techniques such as high - performance liquid chromatography (HPLC) or gas chromatography (GC) are commonly used for purification. In HPLC, the sample is passed through a column filled with a stationary phase, and the melatonin is separated from the impurities based on its differential interaction with the stationary and mobile phases.

Recrystallization: Another purification method is recrystallization. The melatonin extract is dissolved in a suitable solvent at an elevated temperature, and then the solution is slowly cooled. Melatonin crystals will form preferentially, leaving the impurities in the solution. The crystals are then filtered and dried to obtain a purer melatonin product.

3.4 Quality Control

Chemical Analysis: Quality control is crucial in melatonin production. Chemical analysis methods such as spectroscopy (e.g., ultraviolet - visible spectroscopy to measure the absorption of melatonin at a specific wavelength) and mass spectrometry are used to determine the purity and identity of the melatonin product. These methods can detect any contaminants or impurities that may be present in the final product.

Biological Activity Testing: In addition to chemical analysis, the biological activity of the melatonin product needs to be tested. This may involve in vitro assays to determine its antioxidant activity or its ability to regulate circadian rhythms in cell - based models. In vivo studies may also be conducted in animals to evaluate its safety and efficacy.

3.5 Final Packaging

Packaging Materials: Once the melatonin product has passed quality control, it is ready for packaging. The packaging materials should be selected to protect the melatonin from factors such as light, moisture, and oxygen, which can degrade the product. Commonly used packaging materials include amber - colored glass bottles or blister packs with appropriate barrier properties.

Labeling: The packaging should be clearly labeled with information such as the product name, melatonin content, recommended dosage, and any warnings or precautions. This information is essential for consumers to use the product safely and effectively.

4. Conclusion

The extraction and production of melatonin involve a complex series of processes. From the selection of raw materials to the final packaging, each step requires careful consideration and control to ensure the production of a high - quality melatonin product. The development of more efficient, environmentally friendly, and selective extraction techniques will continue to be an area of research focus. Additionally, strict quality control measures are necessary to guarantee the safety and efficacy of melatonin products for consumers.

FAQ:

What are the main extraction techniques for melatonin?

There are several main extraction techniques for melatonin. One common method is solvent extraction, which uses appropriate solvents to dissolve melatonin from the source material. Another technique is supercritical fluid extraction, which takes advantage of the properties of supercritical fluids to selectively extract melatonin. However, solvent extraction may have issues with solvent residue, and supercritical fluid extraction requires specific equipment and operating conditions.

What are the advantages of modern melatonin extraction technologies?

Modern melatonin extraction technologies offer several advantages. For example, some advanced extraction methods can achieve higher purity of melatonin, reducing the presence of impurities. They can also be more efficient in terms of yield, obtaining more melatonin from a given amount of source material. Additionally, newer techniques may be more environmentally friendly, with less waste production compared to traditional methods.

What are the key steps in the melatonin production process?

The melatonin production process has several key steps. It begins with the extraction of melatonin from the source, such as plant materials or synthetic precursors. After extraction, purification steps are carried out to remove impurities. Then, the purified melatonin is typically formulated into a suitable form, which may involve processes like encapsulation or tableting. Finally, it goes through quality control checks before packaging.

How is the purity of melatonin ensured during the production process?

During the production process, the purity of melatonin is ensured through multiple means. Firstly, during the extraction stage, appropriate extraction techniques and solvents are chosen to minimize the extraction of other substances. Purification steps, such as chromatography techniques, are used to separate melatonin from impurities. Regular quality control tests, including spectroscopic and chromatographic analyses, are carried out to monitor and ensure the purity of the final product.

What are the safety considerations in melatonin extraction and production?

In melatonin extraction and production, there are several safety considerations. In extraction, if solvents are used, proper handling and disposal procedures are required to prevent environmental pollution and ensure worker safety. During production, strict quality control is necessary to avoid contamination of the final product. Also, in the packaging stage, appropriate packaging materials should be chosen to ensure the stability and safety of melatonin during storage and transportation.

Related literature

- Advances in Melatonin Extraction Methods"

- "Melatonin Production: From Raw Materials to Final Product"

- "Efficient and Safe Melatonin Extraction Technologies"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Hawthorn Extract

2024-11-29

-

Rose Hip Extract

2024-11-29

-

Black Garlic Extract

2024-11-29

-

Cocoa Extract

2024-11-29

-

Lycopene

2024-11-29

-

Chia Seed Powder

2024-11-29

-

Aguaje Extract

2024-11-29

-

Eucommia Ulmoides Extract

2024-11-29

-

Uridine-5'-monophosphate Disodium salt

2024-11-29

-

Sea buckthorn Juice Powder

2024-11-29