- 0086-571-85302990

- sales@greenskybio.com

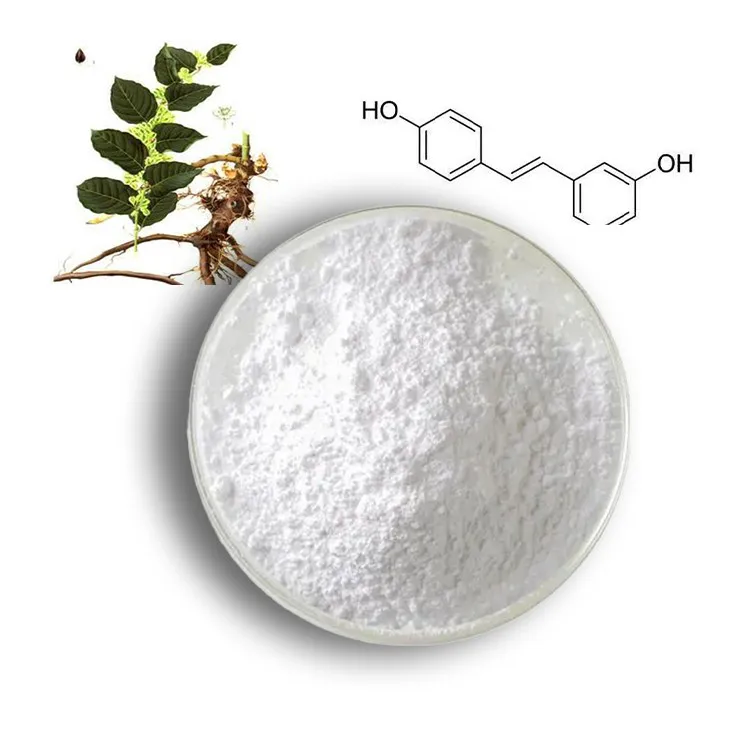

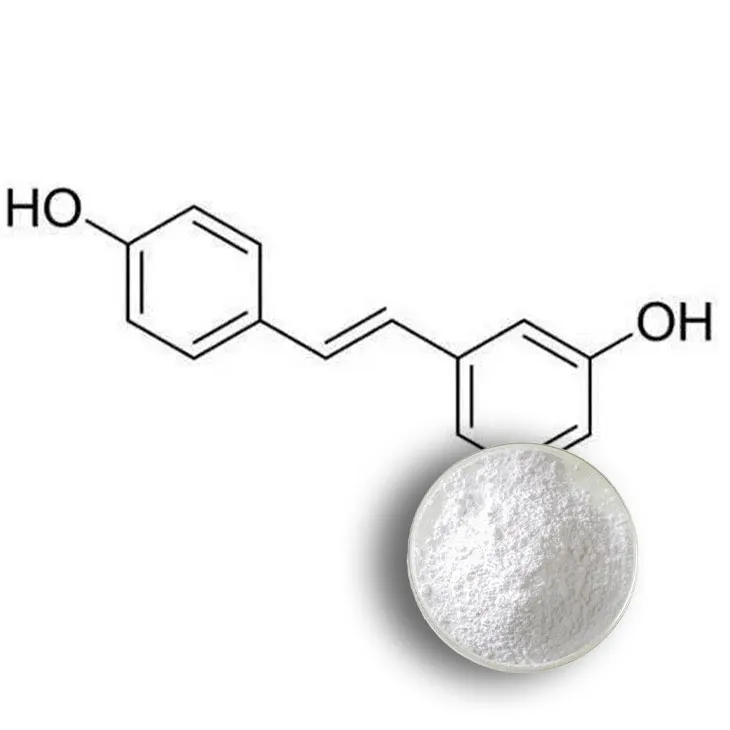

Organic Resveratrol Extract Powder Factory.

2024-11-27

Introduction to Organic Resveratrol

Resveratrol, a remarkable polyphenolic compound, has been garnering significant attention in recent years. It is primarily found in various natural sources such as grapes, berries, and certain other plants. This compound is known for its potential health - promoting properties, which has led to its increasing demand in multiple industries, including dietary supplements, cosmetics, and pharmaceuticals.

The Significance of the Organic Resveratrol extract Powder Factory

The organic Resveratrol extract powder factory serves as a crucial entity in the world of natural health products. It is responsible for isolating and purifying resveratrol from its natural sources, thereby making it available in a concentrated and usable form for various applications.

Raw Material Selection

Emphasis on Organic Sources

At the factory, the selection of raw materials is a meticulous process. Only organic grapes and berries are chosen. This is of utmost importance as it ensures that the final product, the organic Resveratrol extract powder, is free from potentially harmful substances such as pesticides. Organic farming practices are strictly adhered to, which means that the plants are grown without the use of synthetic fertilizers, pesticides, or genetically modified organisms (GMOs).Quality Assurance in Raw Materials

The quality of the raw materials is continuously monitored. Before being accepted into the production process, the grapes and berries are thoroughly inspected. Parameters such as ripeness, freshness, and absence of diseases or contaminants are carefully checked. This initial step sets the foundation for the production of high - quality resveratrol extract powder.

Extraction Techniques

Solvent Extraction

One of the commonly used methods in the factory is solvent extraction. In this process, a suitable solvent is used to dissolve the resveratrol from the plant material. The choice of solvent is crucial as it should be able to selectively extract resveratrol while minimizing the extraction of other unwanted compounds. Commonly used solvents are carefully selected based on their solubility properties and safety profiles. After the extraction, the solvent is then removed through evaporation or other separation techniques, leaving behind the resveratrol extract.Supercritical Fluid Extraction

Another advanced technique employed is supercritical fluid extraction. This method utilizes a supercritical fluid, typically carbon dioxide, which has properties between those of a gas and a liquid. Supercritical carbon dioxide can effectively penetrate the plant material and selectively extract resveratrol. One of the major advantages of this technique is that it is a "green" extraction method, as carbon dioxide is non - toxic and can be easily removed from the final product. It also results in a high - quality extract with a high yield of resveratrol and minimal degradation of its bioactive properties.

Production Process Standardization

Stringent Quality Control at Each Stage

The production process in the factory is highly standardized, with stringent quality control measures in place at every step. From the moment the raw materials enter the factory until the final product is packaged, every aspect is closely monitored. This includes the extraction process, purification steps, and drying and powdering of the resveratrol extract.Initial Raw Material Inspection

As mentioned earlier, the inspection of raw materials is the first line of defense in ensuring quality. Any sub - standard or contaminated raw materials are rejected at this stage. This helps to prevent potential problems in the later stages of production.Intermediate Process Monitoring

During the extraction and purification processes, various parameters are continuously measured and adjusted if necessary. For example, the temperature, pressure, and extraction time in the solvent extraction or supercritical fluid extraction processes are carefully controlled to optimize the yield and quality of the resveratrol extract.Final Product Packaging

Even the final packaging of the organic resveratrol extract powder is a crucial part of the quality control process. The packaging materials are selected to protect the powder from moisture, light, and other environmental factors that could potentially degrade the resveratrol. Additionally, proper labeling is done to provide all the necessary information about the product, including its origin, purity, and recommended usage.Research and Development in the Factory

Exploring New Extraction Efficiency

The factory places a strong emphasis on research and development (R & D). Scientists in the factory are constantly exploring new ways to improve the extraction efficiency of resveratrol. This involves studying different extraction techniques, optimizing process parameters, and evaluating new raw material sources. By improving extraction efficiency, the factory can produce more resveratrol extract powder with the same amount of raw materials, which can lead to cost savings and increased availability of the product.Unraveling Health Benefits

Another important aspect of R & D in the factory is the study of the potential health benefits of resveratrol. Resveratrol has been shown to possess antioxidant, anti - inflammatory, and anti - aging properties. Scientists are conducting in - depth research to further understand how resveratrol exerts these effects at the molecular level. For example, studies are being carried out to determine how resveratrol interacts with cells in the body to scavenge free radicals (antioxidant effect), reduce inflammation markers (anti - inflammatory effect), and slow down the aging process (anti - aging effect).Applications in Different Industries

The knowledge gained from R & D also helps in exploring new applications of resveratrol in different industries. In the dietary supplement industry, resveratrol is being used as an ingredient in products aimed at promoting heart health, boosting the immune system, and improving overall well - being. In the cosmetics industry, its antioxidant and anti - aging properties make it a valuable addition to skincare products such as creams, serums, and lotions, where it can help to reduce wrinkles, improve skin elasticity, and protect the skin from environmental damage. In the pharmaceutical industry, research is ongoing to develop resveratrol - based drugs for the treatment of various diseases, including certain types of cancer, neurodegenerative diseases, and metabolic disorders.Conclusion

The organic resveratrol extract powder factory is not just a production facility but a center of innovation and quality. Through careful raw material selection, advanced extraction techniques, strict production process standardization, and continuous research and development, it plays a vital role in bringing the health - enhancing benefits of resveratrol to various industries and ultimately to consumers. As the demand for natural health products continues to grow, the factory will likely continue to evolve and contribute to the further exploration and utilization of resveratrol's potential.

FAQ:

What are the main raw materials used in the organic resveratrol extract powder factory?

The main raw materials used in the factory are organic grapes and berries. These are carefully selected to ensure the final product is free from pesticides and other harmful substances.

What extraction techniques are employed in the factory?

The factory employs advanced extraction techniques such as solvent extraction and supercritical fluid extraction. These methods help in achieving a high yield of resveratrol while maintaining its integrity and bioactivity.

How does the factory ensure the quality of the organic resveratrol extract powder?

The production process in the factory is highly standardized with stringent quality control measures at every stage. From raw material inspection to final packaging, everything is closely monitored to ensure the highest quality product reaches the market.

Why is research and development important in the organic resveratrol extract powder factory?

Research and development is important as scientists are constantly exploring new ways to improve extraction efficiency and discover more potential health benefits of resveratrol. This includes studying its antioxidant, anti - inflammatory, and anti - aging properties, which are valuable for its use in dietary supplements, cosmetics, and the pharmaceutical industry.

What are the potential applications of the organic resveratrol extract powder?

The organic resveratrol extract powder has potential applications in dietary supplements, cosmetics, and the pharmaceutical industry due to its antioxidant, anti - inflammatory, and anti - aging properties.

Related literature

- Resveratrol: A Review of Preclinical Studies for Human Health"

- "The Role of Resveratrol in Health and Disease"

- "Organic Resveratrol: Production and Health Benefits"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

-

The best organic quercetin.

2024-11-27

-

Nature's Bounty Vitamin K2

2024-11-27

-

Chinese Saffron Extract Powder Factory.

2024-11-27

-

Cactus Extract Supplier

2024-11-27

-

Optimal Bioavailability of Vitamin C.

2024-11-27

-

Purple Sweet Potato Extract

2024-11-27

-

Alfalfa Meal

2024-11-27

-

Saffron Extract Powder

2024-11-27

-

Bayberry Extract

2024-11-27

-

Dandelion Root Extract

2024-11-27

-

Horse Chestnut Extract

2024-11-27

-

Beta Carotene

2024-11-27

-

Gynostemma pentaphyllum extract

2024-11-27

-

Agaricus Blazei Extract

2024-11-27

-

Lily extract

2024-11-27