- 0086-571-85302990

- sales@greenskybio.com

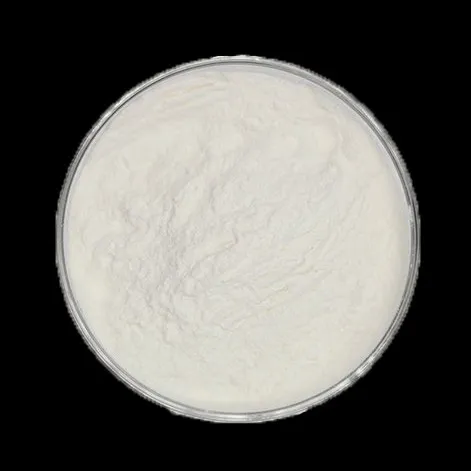

Organic Saw Palmetto Extract Powder Factory.

2024-11-30

1. Introduction to the Factory

A factory specializing in organic Saw Palmetto Extract powder is a unique establishment where the gifts of nature are transformed into a valuable product through scientific processes. Saw palmetto, a remarkable plant known for its significant medicinal potential, serves as the core material in these factories.

2. Sustainable Collection of Saw Palmetto Berries

The collection process is the foundation of the factory's operations. It begins with the sustainable collection of saw palmetto berries. This is a crucial step that requires close cooperation with local farmers or harvesters. These individuals possess in - depth knowledge about the plant and understand the proper time and method for collecting the berries.

Local farmers and harvesters play a vital role. They are well - aware of the seasonal variations and the optimal time to harvest the berries. For example, harvesting too early may result in under - developed berries with lower levels of bioactive compounds, while harvesting too late might lead to a decrease in quality due to over - ripeness or potential damage from environmental factors.

Moreover, sustainable collection methods are adhered to. This means that only a certain percentage of the berries are harvested from each plant or area, allowing the plants to regenerate and maintain a healthy population. It also involves minimizing the impact on the surrounding ecosystem during the collection process.

3. Sorting and Initial Processing of Berries

Once the berries arrive at the factory, they undergo a series of important procedures. The first of these is sorting.

Sorting is essential to remove any damaged, unripe, or foreign matter from the batch of berries. This is typically done using mechanical sieves or by hand - picking in some cases. By removing the sub - standard berries, the factory ensures that only the highest - quality berries are used for further processing.

After sorting, the berries are subjected to initial processing steps. This may include cleaning to remove dirt, debris, and any surface contaminants. This cleaning process is carried out using gentle methods to avoid damaging the berries and the valuable compounds within them.

4. The Extraction Process: A Blend of Tradition and Modern Technology

The extraction process in the factory is a fascinating combination of traditional knowledge and modern technology. Traditional extraction methods have been passed down through generations and have been refined over time. These methods often form the basis of the extraction process.

For example, solvent extraction has been a commonly used traditional method. Organic solvents are used to dissolve the bioactive compounds from the saw palmetto berries. However, modern factories are constantly exploring and implementing new technologies to improve the extraction process.

Ultrasonic - assisted extraction is one such modern technology that is being increasingly explored. Ultrasonic waves are applied during the extraction process. This helps in breaking down the cell walls of the berries more effectively, allowing for a more efficient release of the bioactive components. As a result, a higher - quality extract powder with maximum potency of the bioactive components can be obtained.

Another advantage of modern extraction technologies is their ability to be more environmentally friendly. For instance, some new methods aim to reduce the use of harmful solvents or find more sustainable alternatives. This not only benefits the environment but also meets the growing demand for greener production processes in the market.

5. Quality Assurance in the Factory

Quality assurance in an organic Saw Palmetto Extract powder factory is comprehensive and multi - faceted. It encompasses several important aspects to ensure that the final product is of the highest quality.

Chemical Analysis

Chemical analysis is carried out to determine the exact composition of the extract. This involves using advanced analytical techniques such as high - performance liquid chromatography (HPLC) and gas chromatography - mass spectrometry (GC - MS). These techniques can accurately identify and quantify the various bioactive compounds present in the extract, such as fatty acids, sterols, and flavonoids. By knowing the exact composition, the factory can ensure that the extract powder contains the desired levels of active ingredients and meets the required quality standards.

Microbiological Testing

Microbiological testing is another crucial part of quality assurance. The factory tests for the presence of harmful microorganisms such as bacteria, fungi, and yeasts. This is important to ensure the safety of the product for human consumption. Samples are taken at various stages of the production process and are tested in a microbiology laboratory using standard methods. If any microbial contamination is detected, appropriate measures are taken to eliminate the source of contamination and ensure the product's safety.

Stability Testing

Stability testing is carried out to guarantee the product's shelf - life. The extract powder is subjected to different environmental conditions such as temperature, humidity, and light to simulate real - world storage and transportation conditions. By observing how the product behaves under these conditions, the factory can determine the appropriate packaging and storage instructions. For example, if the extract powder is found to be sensitive to light, it may be packaged in opaque containers to protect it from degradation.6. Educating the Public about Saw Palmetto Extract

The factory also has an important role in educating the public about the benefits of saw palmetto extract. This is achieved through various means.

Proper Labeling is a key aspect of public education. The product labels should clearly state the source of the saw palmetto extract, the extraction method used, and the potential health benefits. For example, it may mention its use in promoting prostate health or its antioxidant properties. Clear and accurate labeling helps consumers make informed decisions about using products containing this extract.

Information Dissemination also plays a significant role. The factory can provide information on its website, through brochures, or at trade shows about the scientific research behind saw palmetto extract and its various applications. This information can help raise awareness among consumers and healthcare professionals alike.

7. International Trade of Organic Saw Palmetto Extract Powder

These factories also play a crucial role in the international trade of organic saw palmetto extract powder. As the demand for natural and organic products grows globally, the export and import of this extract powder have become significant.

Compliance with Import and Export Regulations is essential. Different countries have different regulations regarding the quality, safety, and labeling of food and dietary supplements. The factory must ensure that its products meet all the requirements of the destination countries. This may involve obtaining certifications such as organic certifications, Good Manufacturing Practice (GMP) certifications, and complying with specific import/export documentation requirements.

Meeting Global Quality and Safety Standards is another important aspect of international trade. The factory needs to maintain high - quality production processes to ensure that the organic saw palmetto extract powder is safe and effective for consumers around the world. This includes adhering to international quality standards such as ISO standards for quality management and food safety.

FAQ:

1. How are saw palmetto berries sustainably collected for the factory?

The factory works with local farmers or harvesters. These local partners are well - versed in the appropriate time and method for collecting saw palmetto berries. This ensures that the collection process is sustainable and does not harm the natural environment or the future availability of the plant.

2. What is the significance of using both traditional and modern extraction methods in the factory?

Traditional extraction methods have been refined over time and carry a wealth of knowledge. Modern technologies like ultrasonic - assisted extraction are being explored as well. Combining both allows the factory to obtain a high - quality extract powder. The traditional methods contribute stability and proven results, while modern technologies can enhance the extraction efficiency and potentially increase the potency of the bioactive components in the extract powder.

3. How does the factory ensure the quality of the organic saw palmetto extract powder?

The quality assurance process is comprehensive. Chemical analysis is carried out to precisely determine the composition of the extract. Microbiological testing is done to ensure the safety of the product, and stability testing guarantees its shelf - life. These measures together ensure that the organic saw palmetto extract powder meets the high - quality standards required for both domestic and international markets.

4. What role does the factory play in educating the public?

The factory educates the public through proper labeling and information dissemination. By providing accurate and detailed information about the benefits of saw palmetto extract on product labels and other communication channels, consumers can make well - informed decisions about using products containing this extract.

5. How do these factories comply with international trade regulations?

These factories must adhere to various import and export regulations. This includes meeting quality and safety standards set by different countries. They ensure that the organic saw palmetto extract powder is of consistent quality and safe for consumption on a global scale. This may involve getting certifications and following strict documentation and inspection procedures.

Related literature

- The Medicinal Properties of Saw Palmetto: A Comprehensive Review"

- "Saw Palmetto Extract: Production, Quality Control and Therapeutic Applications"

- "Organic Extracts: Best Practices in the Saw Palmetto Industry"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Pueraria Lobata Extract

2024-11-30

-

Bilberry Extract

2024-11-30

-

Tinospora cordifolia extract

2024-11-30

-

Red Date Extract

2024-11-30

-

Soy Extract

2024-11-30

-

Boswellia Serrata Extract

2024-11-30

-

Moringa powder

2024-11-30

-

Saffron Extract Powder

2024-11-30

-

Cat Claw Extract

2024-11-30

-

Citrus Aurantii Extract

2024-11-30