- 0086-571-85302990

- sales@greenskybio.com

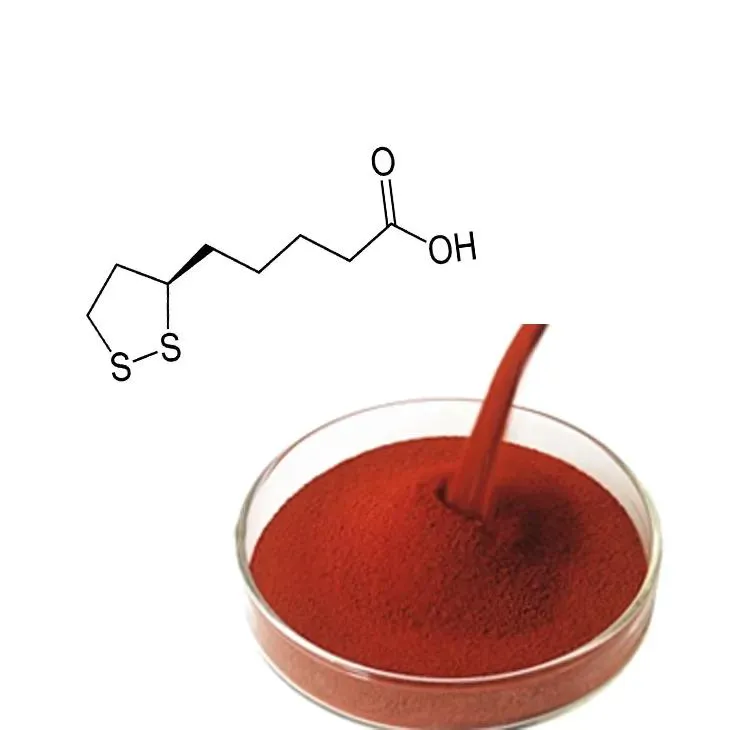

Supercritical carbon dioxide extraction of astaxanthin.

2024-11-28

1. Introduction

Astaxanthin is a remarkable compound that has drawn significant attention in recent years. It is a powerful antioxidant, known for its numerous health - promoting properties. Astaxanthin is predominantly found in marine organisms such as shrimp, salmon, and krill. Given its potential applications in various industries, efficient extraction methods are of great importance. Among the extraction techniques available, supercritical carbon dioxide (CO₂) extraction stands out as a cutting - edge technology.

2. What is Supercritical Carbon Dioxide Extraction?

Supercritical fluid extraction is a process that utilizes a supercritical fluid as the solvent. A supercritical fluid is a substance that is at a temperature and pressure above its critical point. In the case of carbon dioxide, when it is in its supercritical state, it exhibits unique properties. It has the density of a liquid, allowing it to dissolve substances like a liquid solvent, but also has the diffusivity of a gas, which enables it to penetrate solid matrices quickly.

3. Advantages of Supercritical CO₂ Extraction of Astaxanthin

3.1 High - Purity Extraction

One of the key advantages of using supercritical CO₂ for astaxanthin extraction is its ability to achieve high - purity extraction. Supercritical CO₂ can selectively dissolve astaxanthin from the complex matrix of marine organisms. This selectivity is crucial as it allows for the isolation of astaxanthin with minimal contamination from other components present in the source material. For example, in shrimp extracts, there are various lipids, proteins, and other compounds. Supercritical CO₂ can target astaxanthin specifically, resulting in a more pure final product.

3.2 Environmentally Friendly

In comparison to traditional extraction methods, supercritical CO₂ extraction is more environmentally friendly. Traditional extraction methods often involve the use of organic solvents such as hexane or chloroform. These solvents are not only hazardous to human health but also pose a threat to the environment. They can be flammable, toxic, and require proper disposal. On the other hand, carbon dioxide is a non - toxic, non - flammable gas that is abundantly available in the atmosphere. After the extraction process, the CO₂ can be easily recovered and recycled, reducing waste and environmental impact.

3.3 Preservation of Bioactivity

Supercritical CO₂ extraction can operate at relatively low temperatures. This is a significant advantage when it comes to astaxanthin extraction because astaxanthin is a thermally sensitive compound. High - temperature extraction methods can lead to the degradation of astaxanthin and the loss of its bioactivity. By operating at lower temperatures, supercritical CO₂ extraction helps preserve the bioactivity of astaxanthin. This is particularly important for its applications in nutraceuticals and cosmetics, where the bioactive properties of astaxanthin are highly valued.

4. The Process of Supercritical CO₂ Extraction of Astaxanthin

4.1 Preparation of the Feedstock

The first step in the supercritical CO₂ extraction of astaxanthin is the preparation of the feedstock. The marine organisms containing astaxanthin, such as shrimp shells or microalgae, need to be properly processed. This may involve cleaning, drying, and grinding to a suitable particle size. For example, if shrimp shells are used, they need to be thoroughly washed to remove any impurities and then dried to a constant weight. After drying, they are ground into a fine powder to increase the surface area available for extraction.

4.2 The Extraction Chamber

The prepared feedstock is then placed in the extraction chamber. The extraction chamber is a high - pressure vessel where the supercritical CO₂ is introduced. The pressure and temperature in the chamber are carefully controlled to maintain the CO₂ in its supercritical state. The supercritical CO₂ is then allowed to flow through the feedstock, dissolving the astaxanthin. The flow rate of the CO₂, as well as the extraction time, are important parameters that need to be optimized for efficient extraction.

4.3 Separation and Collection

After the extraction, the supercritical CO₂ - astaxanthin mixture is passed into a separation chamber. In this chamber, the pressure is reduced, which causes the CO₂ to return to its gaseous state. As the CO₂ changes phase, its solubility decreases, and the astaxanthin is separated out. The gaseous CO₂ can be recycled back to the extraction process, while the astaxanthin is collected in a suitable container. The collected astaxanthin may then undergo further purification steps, such as filtration or chromatography, to achieve the desired purity.

5. Applications of Astaxanthin Extracted by Supercritical CO₂

5.1 Nutraceuticals

In the field of nutraceuticals, astaxanthin has great potential. It is known for its antioxidant properties, which are much stronger than those of other common antioxidants such as vitamin C and E. Astaxanthin can help protect the body against oxidative stress, which is associated with various chronic diseases such as cardiovascular diseases, cancer, and neurodegenerative disorders. The astaxanthin extracted by supercritical CO₂ can be formulated into dietary supplements in the form of capsules, tablets, or softgels. These products are becoming increasingly popular among health - conscious consumers.

5.2 Cosmetics

Cosmetics is another area where astaxanthin has found wide applications. Its antioxidant and anti - inflammatory properties make it an ideal ingredient in skincare products. Astaxanthin can help reduce skin aging by protecting the skin from UV - induced damage and oxidative stress. It can also improve skin texture and elasticity. In cosmetic formulations, astaxanthin can be incorporated into creams, lotions, serums, and masks. The high - purity astaxanthin obtained through supercritical CO₂ extraction is particularly suitable for these applications as it ensures the quality and effectiveness of the cosmetic products.

5.3 Food Additives

Astaxanthin can also be used as a food additive. It is used to color and enhance the nutritional value of foods. In the aquaculture industry, astaxanthin is added to the feed of salmon and trout to give their flesh the characteristic pink or red color. This not only improves the visual appeal of the fish but also indicates the presence of healthy omega - 3 fatty acids. In addition, astaxanthin can be added to other food products such as juices, yogurts, and baked goods to provide antioxidant benefits. The supercritical CO₂ - extracted astaxanthin is a clean - label ingredient, which is highly desirable in the food industry.

6. Challenges and Future Directions

6.1 Cost - Effectiveness

One of the main challenges associated with supercritical CO₂ extraction of astaxanthin is cost - effectiveness. The equipment required for supercritical fluid extraction is relatively expensive, and the energy consumption during the process can also be high. To make this extraction method more commercially viable, efforts need to be made to optimize the extraction process, reduce equipment costs, and improve energy efficiency. For example, research could focus on developing more efficient extraction systems that can operate at lower pressures and temperatures without sacrificing extraction efficiency.

6.2 Scale - Up

Another challenge is the scale - up of the extraction process. While supercritical CO₂ extraction has been successfully demonstrated at the laboratory and pilot - plant scales, scaling up to industrial - level production can be difficult. Issues such as uniform distribution of the feedstock in large - scale extraction chambers, efficient heat transfer, and mass transfer need to be addressed. To overcome these challenges, further research and development are required to design and optimize large - scale extraction systems.

6.3 Regulatory Considerations

In the development and application of astaxanthin extracted by supercritical CO₂, regulatory considerations play an important role. Different countries and regions have different regulations regarding the use of astaxanthin in nutraceuticals, cosmetics, and food additives. For example, there are limits on the maximum allowable concentration of astaxanthin in food products, and specific purity and quality requirements for its use in nutraceuticals. Manufacturers need to ensure that their products comply with these regulations to enter the market successfully.

Despite these challenges, the future of supercritical CO₂ extraction of astaxanthin looks promising. With continuous research and development, this extraction method is likely to become more cost - effective, scalable, and widely accepted in various industries.

FAQ:

What is supercritical carbon dioxide extraction?

Supercritical carbon dioxide extraction is a method that uses carbon dioxide at its supercritical state (where it has properties of both a liquid and a gas) to extract substances. In this case, it is used to extract astaxanthin from its sources. The supercritical CO₂ can penetrate the material containing astaxanthin and selectively dissolve it, allowing for its separation from other components.

Why is supercritical carbon dioxide extraction better for astaxanthin extraction compared to traditional methods?

There are several reasons. Firstly, it can achieve high - purity extraction as it selectively dissolves astaxanthin. Secondly, it is more environmentally friendly than traditional extraction methods as it produces less waste. Also, it can operate at relatively low temperatures, which is crucial for astaxanthin as it helps preserve the bioactivity of astaxanthin. Traditional methods may use higher temperatures or harsher chemicals that can damage the astaxanthin molecule or reduce its effectiveness.

What are the applications of astaxanthin extracted by supercritical carbon dioxide extraction?

The astaxanthin extracted through this method has great potential in various fields. In nutraceuticals, it can be used as a supplement due to its antioxidant properties. In cosmetics, it can be added to products to help protect the skin from oxidative stress. In food additives, it can be used to color and enhance the nutritional value of food products.

How does supercritical carbon dioxide extraction help preserve the bioactivity of astaxanthin?

Supercritical CO₂ extraction can operate at relatively low temperatures. High temperatures can often cause the denaturation or degradation of bioactive compounds. Since astaxanthin is a bioactive molecule, by using a method that can work at lower temperatures, its chemical structure and thus its bioactivity are more likely to be maintained.

Can supercritical carbon dioxide extraction be used for other substances besides astaxanthin?

Yes, supercritical carbon dioxide extraction can be used for a variety of substances. It is a versatile extraction method that has been applied to extract different types of natural products, essential oils, and other bioactive compounds from plants, fungi, and other organisms. However, the specific extraction parameters may need to be adjusted depending on the nature of the substance to be extracted.

Related literature

- Supercritical Fluid Extraction of Astaxanthin from Haematococcus pluvialis"

- "Optimization of Supercritical Carbon Dioxide Extraction of Astaxanthin - Rich Extracts from Shrimp Waste"

- "Supercritical Fluid Technology for Astaxanthin Extraction and Purification: A Review"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Berberis aristata Extract

2024-11-28

-

Bayberry Extract

2024-11-28

-

Saffron Extract Powder

2024-11-28

-

Alisma Extract

2024-11-28

-

Thunder God Vine Extract

2024-11-28

-

Maca Extract

2024-11-28

-

Coconut Water Powder

2024-11-28

-

Hops Extract

2024-11-28

-

Chasteberry Extract

2024-11-28

-

Oyster Mushroom Extract Powder

2024-11-28