- 0086-571-85302990

- sales@greenskybio.com

The best method for extracting Eucommia ulmoides extracts.

2024-11-27

1. Introduction

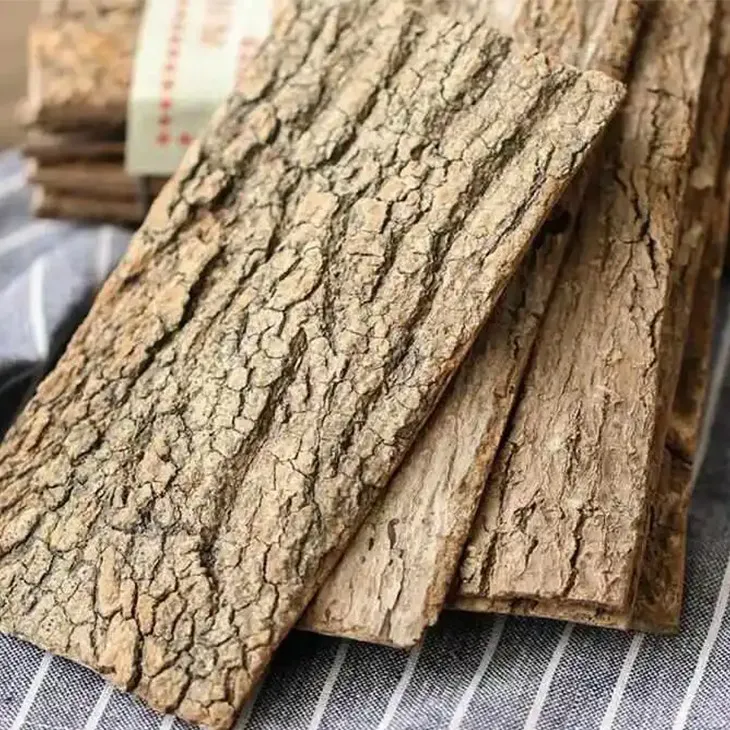

Eucommia ulmoides is a traditional Chinese medicinal plant, which is rich in various bioactive components such as flavonoids, iridoids, lignans, and polysaccharides. These components have a wide range of pharmacological activities, including anti - hypertensive, anti - diabetic, anti - inflammatory, and antioxidant effects. Therefore, the extraction of Eucommia Ulmoides Extracts has attracted increasing attention in recent years. However, the extraction efficiency and quality of the extracts are affected by many factors, such as solvent selection, extraction techniques, extraction time, temperature, and raw material pretreatment. This article will explore the optimal methods for extracting Eucommia Ulmoides Extracts by considering these factors.

2. Solvent Selection

The choice of solvent is crucial for the extraction of Eucommia Ulmoides Extracts. Different solvents have different solubility for the bioactive components in Eucommia ulmoides. Commonly used solvents include water, ethanol, methanol, ethyl acetate, and petroleum ether.

2.1. Water

Water is a green and environmentally friendly solvent. It can extract polysaccharides and some water - soluble components in Eucommia ulmoides. However, the extraction efficiency of hydrophobic components such as flavonoids and lignans is relatively low.

2.2. Ethanol

Ethanol is one of the most widely used solvents for extracting Eucommia ulmoides extracts. It has good solubility for flavonoids, iridoids, and lignans. Ethanol - water mixtures with different proportions can be used to adjust the polarity of the solvent according to the solubility characteristics of different components. For example, a lower proportion of ethanol (e.g., 30% - 50%) can be used to extract more polar components, while a higher proportion of ethanol (e.g., 70% - 90%) is suitable for extracting less polar components.

2.3. Methanol

Methanol also has good solubility for the bioactive components in Eucommia ulmoides. However, methanol is toxic, and its use needs to be carefully controlled in the extraction process. In general, ethanol is preferred over methanol due to its relatively lower toxicity.

2.4. Ethyl acetate and Petroleum ether

Ethyl acetate and petroleum ether are non - polar solvents. They are mainly used to extract non - polar components such as lipids and some hydrophobic lignans. However, these solvents are flammable and volatile, and special safety precautions are required during use.

3. Extraction Techniques

There are several extraction techniques for obtaining Eucommia ulmoides extracts, each with its own advantages and disadvantages.

3.1. Soxhlet extraction

The Soxhlet extraction method is a traditional extraction technique. It uses a Soxhlet extractor to continuously reflux the solvent and the sample, which can ensure a relatively complete extraction of the components in the sample. The process is relatively simple and does not require complex equipment. However, this method usually requires a long extraction time (usually several hours to dozens of hours), and a large amount of solvent is consumed. Moreover, the high - temperature and long - time extraction may cause degradation or transformation of some heat - sensitive components.

- Place the ground Eucommia ulmoides sample in a Soxhlet thimble.

- Add the selected solvent to the Soxhlet flask.

- Set up the Soxhlet extraction apparatus and start the extraction. The solvent will be heated to reflux continuously, and the extract will be collected in the Soxhlet flask.

3.2. Ultrasonic - assisted extraction

Ultrasonic - assisted extraction is a relatively new extraction technique. It uses ultrasonic waves to generate cavitation bubbles in the solvent, which can break the cell walls of the plant material and promote the dissolution of the components. This method has the advantages of short extraction time (usually several minutes to several tens of minutes), high extraction efficiency, and low solvent consumption. However, the extraction effect may be affected by factors such as ultrasonic power, frequency, and extraction time.

- Put the Eucommia ulmoides sample into a container with the selected solvent.

- Place the container in an ultrasonic cleaner and set the appropriate ultrasonic power, frequency, and extraction time.

- After the extraction is completed, separate the extract from the sample residue by filtration or centrifugation.

3.4. Microwave - assisted extraction

Microwave - assisted extraction utilizes microwave energy to heat the solvent and the sample rapidly. The microwave - induced heating can increase the internal temperature and pressure of the plant cells, which promotes the release of the components. This method has the advantages of short extraction time (usually several minutes to tens of minutes), high extraction efficiency, and energy saving. However, the microwave - assisted extraction process needs to be carefully controlled to avoid overheating and degradation of the components.

- Place the Eucommia ulmoides sample and the solvent in a microwave - resistant container.

- Set the appropriate microwave power and extraction time in the microwave oven.

- After the extraction is completed, cool the extract and separate it from the sample residue.

4. Influence of Extraction Time

The extraction time has a significant impact on the extraction efficiency and quality of Eucommia ulmoides extracts. In general, as the extraction time increases, the amount of extracted components also increases. However, if the extraction time is too long, it may lead to the degradation of some components or the extraction of impurities.

For Soxhlet extraction, a longer extraction time is usually required, but it should not be overly long to avoid the degradation of heat - sensitive components. For ultrasonic - assisted extraction and microwave - assisted extraction, shorter extraction times can be achieved, but it is necessary to find the optimal extraction time through experiments to ensure the highest extraction efficiency and the best quality of the extract.

5. Influence of Extraction Temperature

Extraction temperature also plays an important role in the extraction of Eucommia ulmoides extracts. Higher temperatures can generally increase the solubility of the components and promote the extraction efficiency. However, high temperatures may also cause the degradation of some heat - sensitive components.

In Soxhlet extraction, the temperature is mainly determined by the boiling point of the solvent. For ultrasonic - assisted extraction and microwave - assisted extraction, the temperature can be controlled more flexibly. It is necessary to select an appropriate extraction temperature according to the characteristics of the components to be extracted to balance the extraction efficiency and the quality of the extract.

6. Raw Material Pretreatment

The pretreatment of Eucommia ulmoides raw materials can also affect the extraction efficiency and quality of the extracts. Common pretreatment methods include drying, grinding, and sieving.

6.1. Drying

Drying can remove the moisture in the raw materials, which is beneficial to the preservation of the raw materials and the extraction process. Different drying methods such as natural drying, oven drying, and freeze - drying can be used. Freeze - drying can better preserve the bioactive components in the raw materials, but it is relatively expensive.

6.2. Grinding

Grinding can reduce the particle size of the raw materials, increase the contact area between the raw materials and the solvent, and thus improve the extraction efficiency. However, excessive grinding may cause the destruction of some components, so it is necessary to control the grinding degree appropriately.

6.3. Sieving

Sieving can select raw materials with a suitable particle size, which can ensure the uniformity of the extraction process and the quality of the extract.

7. Conclusion

In conclusion, the optimal method for extracting Eucommia ulmoides extracts needs to consider multiple factors such as solvent selection, extraction techniques, extraction time, temperature, and raw material pretreatment. Among them, ethanol - water mixtures are often a good choice for solvents. Ultrasonic - assisted extraction and microwave - assisted extraction are relatively efficient extraction techniques with shorter extraction times compared to Soxhlet extraction. Appropriate control of extraction time and temperature is crucial for ensuring the quality and yield of the extract. And proper raw material pretreatment can also improve the extraction efficiency. Future research can further explore the combination of different extraction methods and optimize the extraction process to obtain high - quality Eucommia ulmoides extracts with high efficiency.

FAQ:

What are the common solvents used for extracting Eucommia ulmoides extract?

Common solvents include ethanol, methanol, water, and sometimes a mixture of these. Ethanol is often preferred as it is relatively safe, can dissolve a wide range of active compounds in Eucommia ulmoides, and is easy to remove during the post - extraction process. Methanol is also effective but is more toxic. Water can be used alone or in combination with organic solvents, especially for extracting water - soluble components.

How does Soxhlet extraction work for Eucommia ulmoides?

In Soxhlet extraction, the Eucommia ulmoides raw material is placed in a Soxhlet thimble. The solvent is continuously evaporated, condensed, and recycled through the sample. This continuous extraction process ensures that the solvent has multiple opportunities to dissolve the desired compounds from the raw material. It is a relatively time - consuming method but can achieve a relatively high extraction yield if the extraction conditions are optimized, such as choosing the right solvent, extraction time, and temperature.

What are the advantages of ultrasonic - assisted extraction for Eucommia ulmoides?

Ultrasonic - assisted extraction has several advantages. Firstly, it can significantly reduce the extraction time compared to traditional extraction methods. The ultrasonic waves create cavitation bubbles in the solvent, which collapse and generate high - energy shockwaves. These shockwaves can disrupt the cell walls of Eucommia ulmoides more effectively, allowing the solvent to access the intracellular components more easily. Secondly, it can often lead to a higher extraction yield and better quality of the extract with less solvent consumption.

How does temperature affect the extraction of Eucommia ulmoides extract?

Temperature has a significant impact on the extraction process. Generally, increasing the temperature can enhance the solubility of the active compounds in the solvent, which may lead to a higher extraction yield. However, if the temperature is too high, it may cause the degradation of some thermo - sensitive compounds in Eucommia ulmoides. Therefore, an optimal temperature range needs to be determined. For example, in ethanol extraction, a temperature between 50 - 70°C may be suitable for most cases, but it may vary depending on the specific components to be extracted.

What is the importance of raw material pretreatment in Eucommia ulmoides extraction?

Raw material pretreatment is crucial. It can improve the extraction efficiency and the quality of the extract. For example, drying the Eucommia ulmoides leaves or bark before extraction can reduce the moisture content, which may otherwise interfere with the extraction process. Grinding the raw material into a fine powder can increase the surface area available for solvent interaction, allowing the solvent to penetrate more easily and extract the active compounds more effectively. Pretreatment may also involve steps like washing to remove impurities that could affect the purity of the final extract.

Related literature

- Optimization of Extraction Conditions for Eucommia ulmoides Oliv. Bark Extracts"

- "A Comparative Study on Different Extraction Methods of Eucommia ulmoides Extract"

- "The Influence of Solvent and Extraction Technique on the Quality of Eucommia ulmoides Extract"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Grape Leaf Extract

2024-11-27

-

Dandelion Root Extract

2024-11-27

-

Reishi mushroom extract

2024-11-27

-

Polygonum Cuspidatum Extract

2024-11-27

-

Clove Powder

2024-11-27

-

Grapefruit Seed Extract Powder

2024-11-27

-

Sea buckthorn Juice Powder

2024-11-27

-

Yam Extract

2024-11-27

-

Cat Claw Extract

2024-11-27

-

Garcinia Cambogia Extract

2024-11-27