- 0086-571-85302990

- sales@greenskybio.com

The extraction process of resveratrol extract.

2024-12-01

1. Introduction

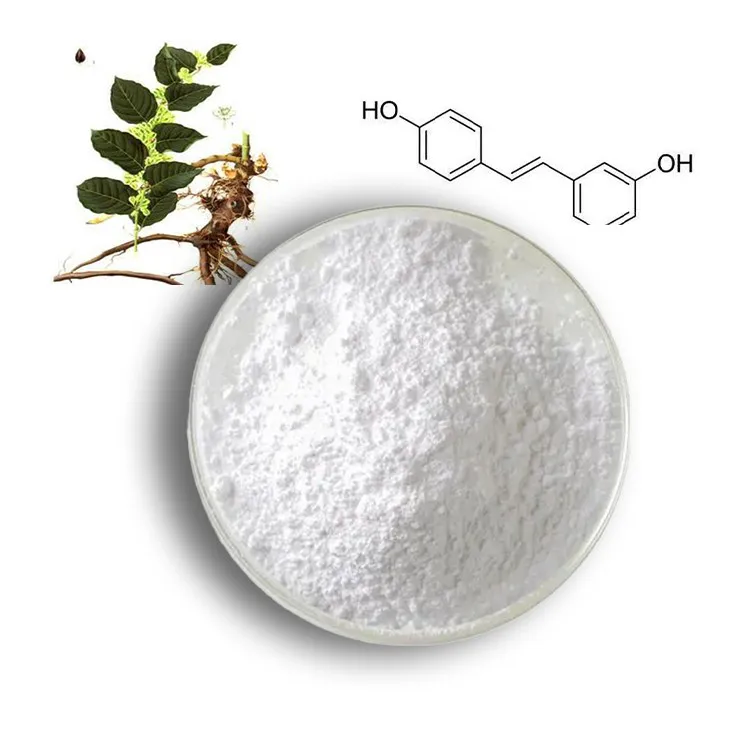

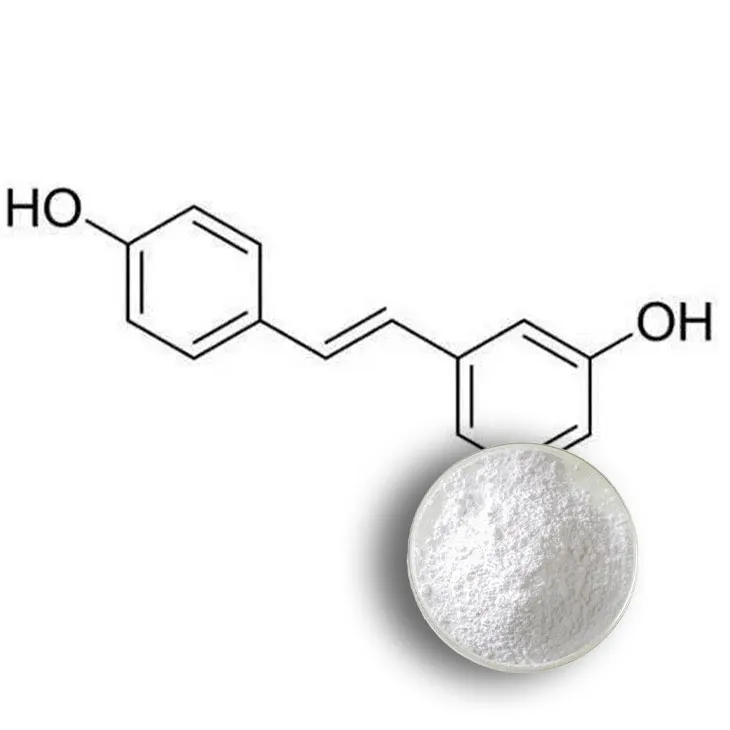

Resveratrol is a compound that has attracted significant attention in recent years due to its potential health benefits. White Resveratrol extract, in particular, has various applications in industries such as pharmaceuticals, cosmetics, and food supplements. The extraction process of white Resveratrol extract is a complex and multi - step procedure that requires careful consideration of various factors to obtain a pure and effective product.

2. Raw material selection

The first and crucial step in the extraction of white Resveratrol extract is the selection of appropriate raw materials. Medicinal plants are often the primary source of resveratrol due to their relatively high content of this compound. Some of the commonly used plants for resveratrol extraction include:

- Grape skins: Grapes are well - known for their resveratrol content, especially in the skins. Different grape varieties may have varying levels of resveratrol, and factors such as the grape - growing region, climate, and cultivation methods can also influence the resveratrol concentration.

- Japanese knotweed: This plant is another rich source of resveratrol. It has been studied extensively for its resveratrol content and is often considered for large - scale extraction processes.

- Peanuts: Peanuts also contain resveratrol, although in relatively lower amounts compared to grape skins and Japanese knotweed. However, they can still be a viable source, especially in regions where peanuts are abundantly grown.

3. Pre - processing of raw materials

Once the raw materials are selected, they need to be pre - processed before the extraction process can begin. This pre - processing stage typically involves the following steps:

- Washing: The raw materials are thoroughly washed to remove any dirt, debris, or contaminants. This is an essential step as it helps to ensure the purity of the final extract. For example, when using grape skins, washing helps to remove any pesticide residues or other impurities that may be present on the surface.

- Chopping or grinding: After washing, the raw materials are chopped or ground into appropriate sizes. This step is important as it increases the surface area of the raw materials, which in turn enhances the efficiency of the subsequent extraction process. For instance, if the raw material is a large - sized plant part like a grapevine stem, chopping it into smaller pieces allows for better solvent penetration during extraction.

4. Solvent extraction

Solvent extraction is a key step in obtaining resveratrol from the pre - processed raw materials. The choice of solvent depends on several factors, including the nature of the raw material and the desired purity of the extract. Different solvents can be used, and each has its own advantages and limitations:

- Hexane: Hexane is a non - polar solvent that can be effective in extracting resveratrol from certain raw materials. It has a relatively low boiling point, which makes it easier to remove during the subsequent purification steps. However, hexane is flammable and requires careful handling. For example, in some extraction processes involving plant materials with a high lipid content, hexane can be used to first extract the lipids along with resveratrol, and then further separation steps are carried out to isolate resveratrol.

- Ethyl acetate: Ethyl acetate is another commonly used solvent for resveratrol extraction. It is a moderately polar solvent that can extract a wide range of compounds, including resveratrol. One of the advantages of ethyl acetate is that it is less toxic compared to some other solvents and has a pleasant smell. It can be used in both small - scale laboratory extractions and large - scale industrial processes. For instance, when extracting resveratrol from grape skins, ethyl acetate can dissolve the resveratrol along with other phenolic compounds, which can then be further purified.

- Alcohol - based solvents: Ethanol and methanol are also considered for resveratrol extraction. These alcohol - based solvents are polar and can be effective in extracting resveratrol from hydrophilic raw materials. Ethanol, in particular, is often preferred due to its relatively low toxicity and wide availability. It can be used in different concentrations depending on the nature of the raw material. For example, in some cases, a higher concentration of ethanol may be required to extract resveratrol from a plant material with a high fiber content.

The solvent extraction process typically involves mixing the pre - processed raw materials with the selected solvent in a suitable container. This mixture is then stirred or shaken for a certain period to allow the solvent to dissolve the resveratrol present in the raw materials. After that, the solvent - containing resveratrol is separated from the remaining solid residue through filtration or centrifugation.

5. Refinement of the extract

The extract obtained from the solvent extraction process contains resveratrol along with other impurities. To obtain a pure white resveratrol extract, refinement or purification steps are necessary. Two common methods used for this purpose are ultra - filtration and reverse - phase chromatography:

5.1 Ultra - filtration

Ultra - filtration is a membrane - based separation process that can be used to remove large - molecular - weight impurities from the resveratrol extract. It works on the principle of size exclusion, where the pores in the ultra - filtration membrane allow smaller molecules (such as resveratrol) to pass through while retaining larger molecules. The steps involved in ultra - filtration are as follows:

- The resveratrol extract is pumped through an ultra - filtration membrane module. The membrane has a specific molecular weight cut - off (MWCO), which is selected based on the size of the impurities to be removed. For example, if there are large - molecular - weight proteins or polysaccharides in the extract, a membrane with an appropriate MWCO can be chosen to exclude these impurities.

- As the extract passes through the membrane, the resveratrol molecules, which are smaller than the MWCO, pass through the pores of the membrane and are collected on the other side. The larger - molecular - weight impurities are retained on the feed side of the membrane.

- The ultra - filtered resveratrol extract is then further processed or stored for subsequent use. Ultra - filtration not only helps in purifying the resveratrol extract but also can concentrate the resveratrol if the process is designed appropriately.

5.2 Reverse - phase chromatography

Reverse - phase chromatography is a powerful separation technique that can precisely separate resveratrol from other similar compounds in the extract. It is based on the differential interaction between the analytes (in this case, resveratrol and other compounds) and the stationary and mobile phases. The steps in reverse - phase chromatography are as follows:

- The resveratrol extract is loaded onto a reverse - phase chromatography column. The column is typically filled with a stationary phase material, such as a hydrophobic silica - based packing material.

- A mobile phase, which is a solvent or a mixture of solvents, is then pumped through the column. The choice of mobile phase depends on the nature of the analytes and the desired separation. For resveratrol separation, a mobile phase consisting of a mixture of water and an organic solvent (such as acetonitrile or methanol) is often used.

- As the mobile phase flows through the column, the different compounds in the extract interact differently with the stationary and mobile phases. Resveratrol, being relatively hydrophobic, has a different retention time compared to other more hydrophilic or less hydrophobic compounds. This difference in retention time allows resveratrol to be separated from the other compounds and eluted from the column at a specific time.

- The purified resveratrol fraction is then collected and can be further dried or concentrated if required.

6. Conclusion

The extraction process of white resveratrol extract is a complex and sophisticated procedure that involves multiple steps from raw material selection to final refinement. Each step plays a crucial role in obtaining a pure and effective resveratrol product. The careful selection of raw materials, proper pre - processing, appropriate solvent extraction, and efficient refinement methods are all necessary to meet the requirements of different industries such as pharmaceuticals, cosmetics, and food supplements. As research in the field of resveratrol continues to progress, it is expected that the extraction process will also be further optimized to improve the quality and yield of white resveratrol extract.

FAQ:

What are the common raw materials for resveratrol extract?

Some medicinal plants are common raw materials for resveratrol extract as they often have a relatively high resveratrol content.

Why is pre - processing of raw materials necessary?

Pre - processing such as washing and chopping the raw materials into appropriate sizes is necessary. Washing can remove dirt and impurities, and chopping to the right size helps in better solvent extraction as it increases the surface area exposed to the solvent.

How to choose the solvent for extraction?

The choice of solvent depends on the nature of the raw material and the desired purity of the extract. For example, hexane or ethyl acetate might be considered in some cases. The solubility of resveratrol in different solvents and the potential interference of the solvent with other components in the raw material are important factors to consider.

What is the role of ultra - filtration in the extraction process?

Ultra - filtration plays the role of removing large - molecular - weight impurities in the extract obtained from solvent extraction. This helps in purifying the resveratrol extract and making it closer to the desired purity level.

Why is reverse - phase chromatography used?

Reverse - phase chromatography is used because it can precisely separate resveratrol from other similar compounds. This is crucial for obtaining a pure resveratrol extract as there may be other substances in the initial extract that are chemically similar to resveratrol.

Related literature

- Resveratrol: Sources, Bioavailability, and Potential Health Benefits"

- "Advances in Resveratrol Extraction and Purification Techniques"

- "Resveratrol Extract: Production, Quality Control, and Applications"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Honeysuckle Pollen

2024-12-01

-

Baicalin

2024-12-01

-

Peppermint Oil

2024-12-01

-

Sea buckthorn oil

2024-12-01

-

Feverfew Extract

2024-12-01

-

Buckthorn bark extract

2024-12-01

-

Hawthorn powder

2024-12-01

-

Mulberry Extract

2024-12-01

-

Polygonum Cuspidatum Extract

2024-12-01

-

Oat Straw Extract Powder

2024-12-01