- 0086-571-85302990

- sales@greenskybio.com

The Optimal Method for Extracting Diosmin.

2024-11-30

1. Introduction

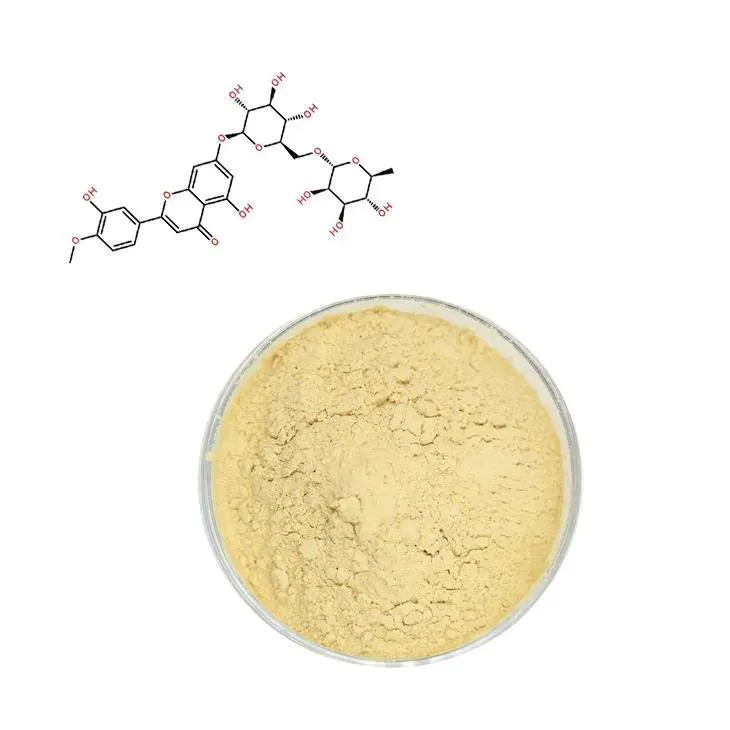

Diosmin is a flavonoid glycoside that has been widely studied for its various pharmacological properties, such as antioxidant, anti - inflammatory, and vascular protective effects. Efficient extraction of Diosmin from natural sources is of great significance for its further application in the pharmaceutical, nutraceutical, and cosmetic industries. However, the extraction process needs to consider multiple factors to ensure safety, efficiency, and reproducibility.

2. Sources of Diosmin

Diosmin is mainly found in citrus fruits, especially in the peels. Other plant sources may also contain diosmin, but citrus peels are the most common and rich source. Citrus peels are usually considered as a by - product in the citrus processing industry, which makes them an economical and sustainable source for diosmin extraction.

3. Traditional Extraction Methods

3.1 Solvent Extraction

- Solvent extraction is one of the most commonly used traditional methods for diosmin extraction. Ethanol, methanol, and water - ethanol mixtures are often used as solvents.

- The process typically involves soaking the plant material (such as citrus peels) in the solvent for a certain period of time, followed by filtration and evaporation to obtain the diosmin extract. For example, in a study, citrus peels were soaked in 70% ethanol for 24 hours at room temperature. The extract obtained after filtration and evaporation showed a certain amount of diosmin content.

- However, solvent extraction has some drawbacks. The use of organic solvents may pose safety risks due to their flammability and toxicity. Also, the extraction efficiency may not be very high, and it may require a large amount of solvent and long extraction time.

3.2 Soxhlet Extraction

- The Soxhlet extraction method is another traditional approach. It uses a Soxhlet apparatus, which continuously circulates the solvent through the plant material.

- This method can improve the extraction efficiency compared to simple solvent extraction. For instance, when using Soxhlet extraction with ethanol as the solvent for citrus peels, a relatively higher yield of diosmin can be obtained compared to normal solvent soaking.

- Nevertheless, Soxhlet extraction also has limitations. It is a time - consuming process, usually taking several hours to days. Moreover, the large - scale use of the Soxhlet apparatus may be inconvenient and costly, and the use of organic solvents still brings safety concerns.

4. Modern Extraction Technologies

4.1 Supercritical Fluid Extraction (SFE)

- Supercritical fluid extraction (SFE) is a modern and advanced extraction technology. Supercritical carbon dioxide (scCO₂) is the most commonly used supercritical fluid in diosmin extraction.

- The principle of SFE is based on the unique properties of supercritical fluids, which have the diffusivity of gases and the density of liquids. When scCO₂ is used, it can penetrate into the plant material easily and dissolve the diosmin effectively. For example, in some experiments, scCO₂ was used at a certain pressure and temperature to extract diosmin from citrus peels, and the results showed a high extraction efficiency.

- One of the major advantages of SFE is its environmental - friendliness. Since CO₂ is non - toxic, non - flammable, and easily recoverable, it reduces the environmental impact compared to traditional organic solvents. Also, SFE can provide a relatively pure extract with less impurities.

- However, the equipment for SFE is relatively expensive, which may limit its widespread application in small - scale or low - budget extraction processes.

4.2 Microwave - Assisted Extraction (MAE)

- Microwave - assisted extraction (MAE) is another modern extraction method. It utilizes microwave energy to heat the plant material and solvent mixture, which accelerates the extraction process.

- In the case of diosmin extraction from citrus peels, MAE can significantly reduce the extraction time. For example, compared to traditional solvent extraction, MAE can complete the extraction within a few minutes to tens of minutes, depending on the microwave power and other parameters.

- MAE also has the potential to improve the extraction efficiency. The microwave energy can disrupt the cell walls of the plant material more effectively, facilitating the release of diosmin. However, the method requires careful control of the microwave power and extraction time to avoid over - heating and degradation of the target compound.

4.3 Ultrasound - Assisted Extraction (UAE)

- Ultrasound - assisted extraction (UAE) is a popular modern extraction technology. It uses ultrasonic waves to create cavitation bubbles in the solvent - plant material system.

- These cavitation bubbles collapse and generate high - pressure and high - temperature micro - environments, which can enhance the mass transfer between the solvent and the plant material. In the extraction of diosmin from citrus peels, UAE can improve the extraction efficiency. For example, it has been shown that UAE can increase the yield of diosmin compared to traditional solvent extraction methods.

- UAE is relatively simple to operate and does not require expensive equipment like SFE. It is also more energy - efficient compared to some other methods. However, the extraction efficiency may still be affected by factors such as ultrasound frequency, power, and extraction time.

5. Comparison of Different Extraction Methods

- Safety: In terms of safety, SFE using supercritical CO₂ is the most favorable as CO₂ is non - toxic and non - flammable. MAE and UAE are also relatively safe compared to traditional solvent extraction methods that use flammable and toxic organic solvents. However, MAE needs to pay attention to the control of microwave power to avoid potential safety hazards.

- Efficiency: SFE and UAE generally show high extraction efficiencies. SFE can achieve high - purity extraction due to the unique properties of supercritical fluids. UAE can effectively disrupt the cell structure of plant materials through cavitation effects to improve extraction efficiency. MAE can significantly reduce the extraction time, which also reflects its high efficiency in a sense. However, traditional solvent extraction methods such as Soxhlet extraction are relatively less efficient.

- Reproducibility: SFE has good reproducibility as long as the pressure, temperature, and other parameters are well - controlled. UAE also shows relatively stable reproducibility. MAE may be slightly affected by the uniformity of microwave heating, but with proper control, it can also achieve good reproducibility. Traditional solvent extraction methods may be more affected by factors such as solvent concentration and extraction time, resulting in relatively poorer reproducibility.

6. Optimization of the Extraction Process

- For SFE, the optimization of parameters such as pressure, temperature, and flow rate of scCO₂ is crucial. By adjusting these parameters, the extraction efficiency can be maximized while maintaining the quality of the extract. For example, increasing the pressure within a certain range can increase the solubility of diosmin in scCO₂, but too high a pressure may also lead to the extraction of unwanted impurities.

- In the case of MAE, the optimization of microwave power, extraction time, and solvent - to - material ratio is important. A proper microwave power can ensure efficient heating without causing degradation of diosmin. The extraction time should be balanced to obtain a sufficient yield without over - extraction. The solvent - to - material ratio also affects the extraction efficiency.

- For UAE, the optimization of ultrasound frequency, power, and extraction time is necessary. Different plant materials may respond differently to ultrasound parameters. For diosmin extraction from citrus peels, finding the optimal ultrasound frequency and power can improve the extraction efficiency significantly.

7. Conclusion

Among the various extraction methods for diosmin, each has its own advantages and disadvantages. Supercritical fluid extraction (SFE) shows great potential in terms of safety, efficiency, and reproducibility, especially when using supercritical CO₂. However, its high equipment cost may limit its application in some cases. Microwave - assisted extraction (MAE) and ultrasound - assisted extraction (UAE) are also excellent alternatives, which are relatively more cost - effective and can also achieve good extraction results. In practice, the choice of the optimal extraction method should be based on factors such as the scale of production, cost - effectiveness, and the required quality of the extract. By further optimizing the extraction process parameters of these methods, more efficient and high - quality diosmin extraction can be achieved.

FAQ:

What are the main factors to consider in diosmin extraction?

When extracting diosmin, several main factors need to be considered. Firstly, the choice of solvent is crucial as it affects the solubility of diosmin and the extraction efficiency. Different solvents may have different affinities for diosmin. Secondly, extraction time and temperature play important roles. Longer extraction times may increase the yield but could also lead to the degradation of diosmin if the temperature is not properly controlled. Thirdly, the purity of the raw material containing diosmin can influence the extraction process. Impurities in the raw material may interfere with the extraction or require additional purification steps.

How does the choice of solvent impact diosmin extraction?

The choice of solvent has a significant impact on diosmin extraction. Solvents with a high affinity for diosmin can dissolve it more effectively, leading to a higher extraction yield. For example, some organic solvents may be better at dissolving diosmin compared to water. However, the solvent should also be safe, non - toxic, and easy to handle. Additionally, the polarity of the solvent is an important factor. If the solvent polarity matches well with the chemical properties of diosmin, it can enhance the extraction process. But inappropriate solvents may also extract other unwanted substances along with diosmin, which requires further purification.

What are the safety concerns in diosmin extraction?

In diosmin extraction, safety concerns are multi - faceted. If using organic solvents, they may be flammable, volatile, or toxic. For example, some solvents can pose a risk of fire if not handled properly in a laboratory or industrial setting. Moreover, inhalation of solvent vapors can be harmful to human health. Also, during the extraction process, if high temperatures or pressures are involved, there are potential risks of equipment failure and associated safety hazards. Ensuring proper ventilation, using appropriate personal protective equipment, and following strict safety protocols are essential to address these safety concerns.

How can the efficiency of diosmin extraction be improved?

To improve the efficiency of diosmin extraction, several methods can be employed. Optimizing the extraction parameters such as extraction time, temperature, and solvent - to - sample ratio is crucial. Using modern extraction techniques like microwave - assisted extraction or ultrasound - assisted extraction can also enhance the efficiency. These techniques can accelerate the mass transfer process, allowing diosmin to be extracted more quickly and completely. Additionally, pre - treating the raw material, such as grinding or sieving, can increase the surface area available for extraction, which in turn improves the extraction efficiency.

What is the importance of reproducibility in diosmin extraction?

Reproducibility is of great importance in diosmin extraction. In scientific research and industrial production, if the extraction process is reproducible, it means that the same results can be obtained under the same experimental or production conditions. This allows for accurate comparison of different extraction methods, quality control in production, and reliable scientific research. If the extraction process lacks reproducibility, it is difficult to determine the effectiveness of a particular method, and it may lead to inconsistent product quality.

Related literature

- Optimization of Diosmin Extraction from Citrus Peel"

- "Advanced Techniques for Efficient Diosmin Extraction"

- "Safety Considerations in Diosmin Extraction Processes"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Ivy Extract

2024-11-30

-

Maca Extract

2024-11-30

-

Thunder God Vine Extract

2024-11-30

-

Sea buckthorn oil

2024-11-30

-

Avocado Extract Powder

2024-11-30

-

Mangosteen extract powder

2024-11-30

-

Mulberry Extract

2024-11-30

-

Saw Palmetto Extract

2024-11-30

-

Medicinal Marshmallow Extract

2024-11-30

-

Senna Leaf Extract

2024-11-30