- 0086-571-85302990

- sales@greenskybio.com

The process of extracting astaxanthin liposomes from astaxanthin.

2024-12-01

1. Introduction

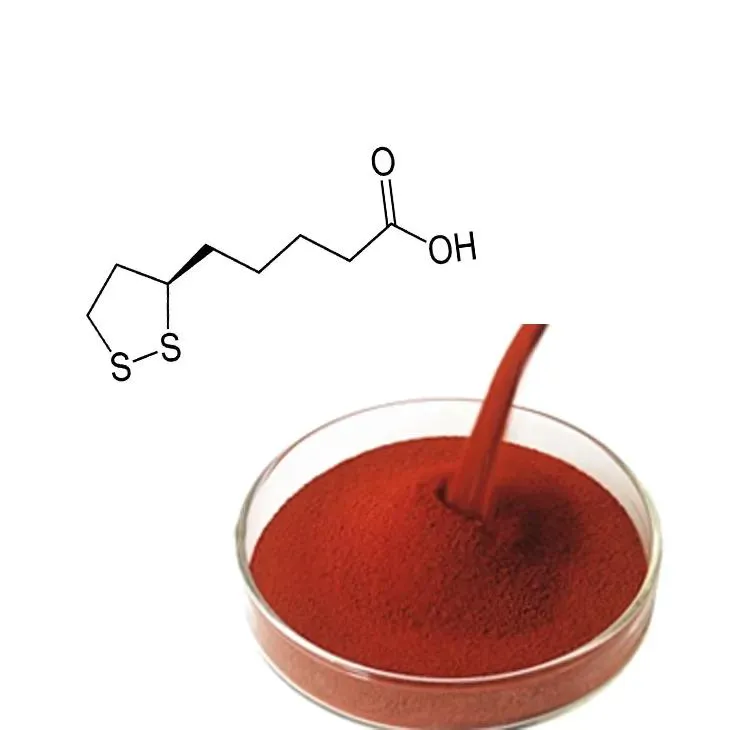

Astaxanthin is a powerful antioxidant known for its numerous health benefits and potential applications in various industries, such as food, cosmetics, and pharmaceuticals. Astaxanthin liposomes, on the other hand, are lipid - based vesicles that can encapsulate Astaxanthin, enhancing its bioavailability and stability. The extraction of astaxanthin liposomes from astaxanthin is a complex process that involves multiple steps and considerations. This review aims to provide a comprehensive understanding of this process, including the techniques used, raw material sources, and quality control aspects.

2. Raw Material Sources of Astaxanthin

2.1. Microalgae Microalgae are one of the primary sources of astaxanthin. Haematococcus pluvialis, in particular, is a well - known microalga that can accumulate high levels of astaxanthin. It has the ability to synthesize astaxanthin under stress conditions, such as high light intensity, nutrient deficiency, or high salinity. The cultivation of Haematococcus pluvialis involves several stages, including growth in a nutrient - rich medium under controlled environmental conditions, followed by induction of astaxanthin synthesis through stress application.

2.2. Crustaceans Another source of astaxanthin is crustaceans, such as shrimps, crabs, and krill. In these organisms, astaxanthin is present in their exoskeletons and tissues. However, the extraction from crustaceans is more complex due to the presence of other components, and there are also ethical and environmental concerns associated with large - scale extraction from these sources.

2.3. Synthetic Astaxanthin Synthetic astaxanthin is also available in the market. It is produced through chemical synthesis methods. Although it can be produced in large quantities, there are concerns regarding its purity and potential differences in biological activity compared to natural astaxanthin.

3. Techniques for Extracting Astaxanthin

3.1. Organic Solvent Extraction

- One of the common methods for extracting astaxanthin from its sources is organic solvent extraction. This method involves the use of organic solvents such as hexane, acetone, or ethyl acetate.

- The raw material is first ground or homogenized to break the cell walls and release the astaxanthin. Then, the organic solvent is added, and the mixture is stirred or sonicated to facilitate the extraction process.

- After extraction, the solvent is evaporated to obtain the crude astaxanthin extract. However, this method has some drawbacks, such as the potential for solvent residues in the final product, which may pose safety risks, and the requirement for careful handling of the solvents due to their flammability and toxicity.

3.2. Supercritical Fluid Extraction (SFE)

- Supercritical fluid extraction is a more advanced technique for astaxanthin extraction. In this method, supercritical carbon dioxide (scCO₂) is often used as the extraction fluid.

- The supercritical state of carbon dioxide has properties between a gas and a liquid, allowing it to penetrate the raw material effectively and extract astaxanthin with high selectivity.

- SFE has several advantages over organic solvent extraction, including the absence of solvent residues, lower extraction temperatures that can preserve the integrity of astaxanthin, and the ability to control the extraction process more precisely. However, the equipment for SFE is relatively expensive, which may limit its widespread application.

4. Formation of Astaxanthin Liposomes

4.1. Liposome Preparation Methods

- There are several methods for preparing astaxanthin liposomes. One of the commonly used methods is the thin - film hydration method. In this method, a lipid mixture, which may include phospholipids such as phosphatidylcholine, is dissolved in an organic solvent.

- The solution is then evaporated to form a thin lipid film on the wall of a container. Astaxanthin, either in its pure form or as an extract, is then added, followed by the addition of an aqueous buffer.

- The mixture is hydrated, and liposomes are formed through agitation or sonication. Another method is the reverse - phase evaporation method, which involves the formation of an emulsion of the lipid and organic solvent in an aqueous phase, followed by evaporation of the organic solvent to form liposomes.

4.2. Factors Affecting Liposome Formation

- The type and concentration of lipids play a crucial role in liposome formation. Different lipids can result in liposomes with different sizes, stabilities, and encapsulation efficiencies.

- The ratio of astaxanthin to lipids also affects the properties of the formed liposomes. A higher ratio of astaxanthin may lead to overloading of the liposomes, which can affect their stability and release characteristics.

- The method of preparation, such as the intensity and duration of sonication or agitation, can influence the size and homogeneity of the liposomes.

5. Quality Control Aspects

5.1. Purity and Identity Testing

- Ensuring the purity and identity of astaxanthin liposomes is essential. High - performance liquid chromatography (HPLC) is often used to separate and quantify astaxanthin in the liposome preparation.

- Spectroscopic techniques, such as ultraviolet - visible (UV - Vis) spectroscopy and infrared (IR) spectroscopy, can also be used to confirm the presence of astaxanthin and to study its chemical structure within the liposomes.

5.2. Stability Testing

- The stability of astaxanthin liposomes is a critical factor for their applications. Stability testing involves evaluating the liposomes under different storage conditions, such as temperature, humidity, and light exposure.

- Encapsulation efficiency is an important parameter in stability testing. It can be measured by determining the amount of astaxanthin that remains encapsulated within the liposomes over time.

- The release profile of astaxanthin from the liposomes is also studied. This can be done by simulating physiological conditions and monitoring the release of astaxanthin over a period of time.

5.3. Safety Evaluation

- Since astaxanthin liposomes may be used in food, cosmetics, and pharmaceutical products, safety evaluation is necessary. Toxicity studies are carried out to determine the potential adverse effects of astaxanthin liposomes on living organisms.

- Microbiological testing is also performed to ensure that the liposome preparations are free from harmful microorganisms.

6. Applications of Astaxanthin Liposomes

6.1. Food Industry

- In the food industry, astaxanthin liposomes can be used as a natural colorant. They can provide a red - orange color to food products, such as beverages, confectionery, and dairy products.

- Astaxanthin liposomes can also be added to functional foods due to their antioxidant properties. They can help in preventing lipid oxidation in food products, thereby increasing their shelf - life.

6.2. Cosmetics Industry

- In the cosmetics industry, astaxanthin liposomes are used for their anti - aging and skin - protecting properties. They can penetrate the skin more effectively than free astaxanthin, protecting the skin from UV damage, reducing wrinkles, and improving skin elasticity.

- Astaxanthin liposomes can also be incorporated into hair care products to improve hair health, such as reducing hair breakage and enhancing hair shine.

6.3. Pharmaceutical Industry

- In the pharmaceutical industry, astaxanthin liposomes have potential applications in drug delivery systems. They can be used to encapsulate drugs, improving their solubility, bioavailability, and targeted delivery to specific tissues or cells.

- Astaxanthin itself has some pharmacological properties, such as anti - inflammatory and antioxidant activities. When encapsulated in liposomes, these properties can be further enhanced, making it potentially useful for the treatment of various diseases, such as cardiovascular diseases, neurodegenerative diseases, and cancer.

7. Conclusion

The extraction of astaxanthin liposomes from astaxanthin is a multi - faceted process that involves careful consideration of raw material sources, extraction techniques, liposome formation methods, and quality control aspects. Each step in the process plays a crucial role in obtaining high - quality astaxanthin liposomes with desirable properties for various applications in the food, cosmetics, and pharmaceutical industries. As research continues, it is expected that more efficient and sustainable methods for astaxanthin liposome extraction will be developed, further expanding the potential applications of this valuable compound.

FAQ:

What are the main techniques for extracting astaxanthin liposomes from astaxanthin?

There are several main techniques. One common method is the solvent - extraction method, where appropriate solvents are used to dissolve astaxanthin and then form liposomes through a series of physical and chemical processes. Another technique involves supercritical fluid extraction, which utilizes supercritical fluids with unique properties to extract and transform astaxanthin into liposomes. Additionally, micro - emulsion - based methods are also explored, which can help in the formation of astaxanthin liposomes in a more controlled and efficient manner.

What are the suitable raw material sources for astaxanthin in the extraction of astaxanthin liposomes?

There are various raw material sources. Haematococcus pluvialis is a very popular source as it is rich in astaxanthin. Microalgae in general can be good sources due to their ability to produce high - quality astaxanthin. Some crustaceans, such as shrimp and krill, also contain astaxanthin and can potentially be used as raw materials. However, different sources may have different extraction challenges and require different pre - treatment methods.

How important is quality control in the extraction of astaxanthin liposomes from astaxanthin?

Quality control is extremely important. Firstly, it ensures the purity of the astaxanthin liposomes. Impurities can affect the functionality and stability of the liposomes. Secondly, it helps in maintaining consistent product quality. This is crucial for applications in industries such as pharmaceuticals and cosmetics where strict quality standards are required. Quality control also involves monitoring the size and shape of the liposomes, as well as their encapsulation efficiency, to ensure that they can perform their intended functions effectively.

What are the potential applications of astaxanthin liposomes in different industries?

In the pharmaceutical industry, astaxanthin liposomes can be used for drug delivery systems due to their ability to encapsulate drugs and target specific cells. In the cosmetics industry, they are often used in anti - aging and skin - protecting products because of astaxanthin's antioxidant properties. In the food industry, they can be added as a functional ingredient to improve the nutritional value and shelf - life of products. In the nutraceutical industry, astaxanthin liposomes are popular as dietary supplements because of their potential health benefits.

What are the challenges faced during the extraction of astaxanthin liposomes from astaxanthin?

One of the main challenges is the instability of astaxanthin. It is highly sensitive to factors such as light, heat, and oxygen, which can lead to degradation during the extraction process. Another challenge is achieving high encapsulation efficiency. It is difficult to ensure that a large amount of astaxanthin is effectively encapsulated into liposomes. The cost of extraction can also be a challenge, especially when using some advanced extraction techniques or high - quality raw materials. Additionally, regulatory compliance for different industries can be complex and challenging to meet.

Related literature

- Astaxanthin: Sources, Extraction, Stability, Biological Activities and Its Commercial Applications"

- "Advances in Astaxanthin Production and Application"

- "Liposome - Based Delivery Systems for Astaxanthin: A Review"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Epimedium extract powder

2024-12-01

-

Pomegranate Extract

2024-12-01

-

Giant Knotweed Extract

2024-12-01

-

Green Tea Extract

2024-12-01

-

Lemon Extract

2024-12-01

-

Hesperidin

2024-12-01

-

Carrageenan Extract Powder

2024-12-01

-

Kupilu Extract

2024-12-01

-

Tongkat Ali Extract

2024-12-01

-

Grapefruit Seed Extract Powder

2024-12-01