- 0086-571-85302990

- sales@greenskybio.com

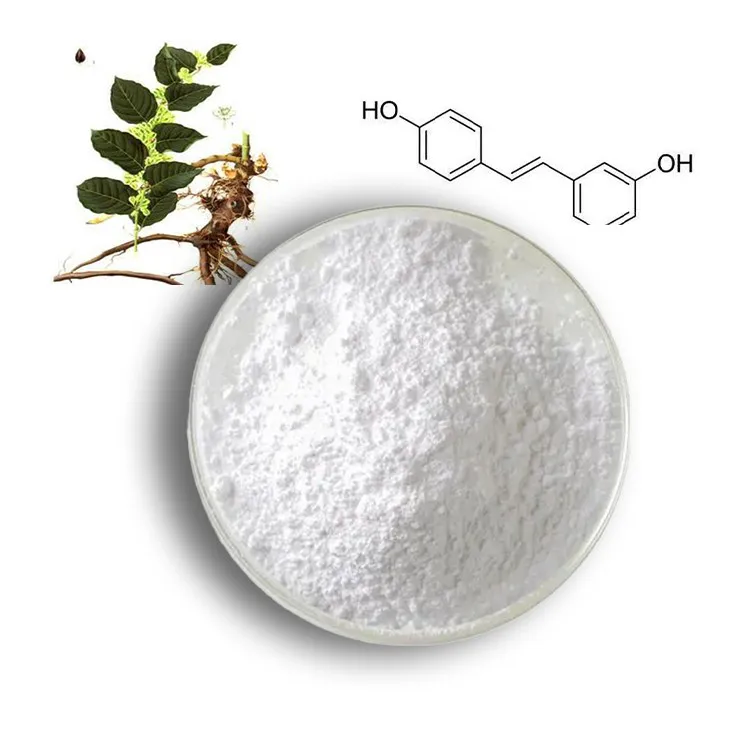

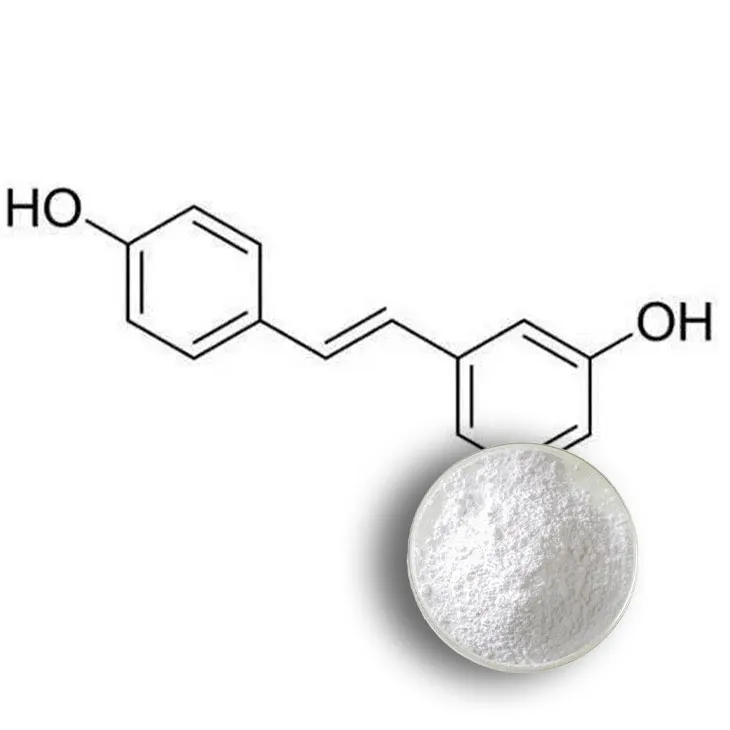

The process of extracting high - purity resveratrol from resveratrol extracts.

2024-11-27

1. Introduction

Resveratrol, a well - known polyphenol, has attracted significant attention in various fields such as anti - aging research, anti - cancer studies, and cardiovascular disease prevention. However, it is initially present in Resveratrol extracts along with numerous other substances. Therefore, the extraction of high - purity resveratrol from these extracts is a crucial process. This article will comprehensively discuss the process of obtaining high - purity resveratrol.

2. Solvent Extraction

2.1 Principles of Solvent Extraction

Solvent extraction is often the initial step in the extraction of high - purity resveratrol. Different solvents are chosen based on their ability to dissolve resveratrol preferentially. The principle behind this is that resveratrol has specific solubility characteristics, and by selecting an appropriate solvent, it can be separated from other substances in the extract to a certain extent. For example, some organic solvents like ethanol and methanol are commonly considered due to their relatively good solubility for resveratrol.2.2 Selection of Solvents

- Ethanol: Ethanol is a popular solvent choice. It has several advantages. It is relatively safe to handle compared to some more toxic solvents. Moreover, it can effectively dissolve resveratrol while also having the ability to separate resveratrol from some water - soluble impurities. The solubility of resveratrol in ethanol varies with temperature and concentration. At appropriate temperatures and concentrations, a higher yield of resveratrol can be achieved during the extraction process.

- Methanol: Methanol also has good solubility for resveratrol. However, it is more toxic than ethanol, which requires more careful handling during the extraction process. But in some cases, where a higher extraction efficiency for resveratrol is required, methanol may be considered. The choice between methanol and ethanol often depends on factors such as the nature of the Resveratrol extract, the required purity of the final product, and safety considerations in the extraction process.

2.3 Procedure of Solvent Extraction

- The Resveratrol extract is first mixed with the selected solvent in an appropriate ratio. This ratio is determined based on preliminary experiments and the characteristics of the extract. For example, if using ethanol, a common ratio might be 1:5 (extract:solvent) by mass, but this can be adjusted according to the actual situation.

- The mixture is then stirred thoroughly. Stirring can be carried out at a certain speed and for a specific duration. Usually, a magnetic stirrer or mechanical stirrer can be used. The stirring time may range from several hours to a day, depending on the complexity of the extract and the desired extraction efficiency.

- After stirring, the mixture is allowed to stand for a period of time to allow for phase separation. Resveratrol - rich solvent phase and the residue phase will separate. The solvent phase containing resveratrol is then carefully collected for further processing.

3. Membrane Separation Technology

3.1 Principles of Membrane Separation

After solvent extraction, membrane separation technology can be utilized to further purify the resveratrol - containing solution. Membrane separation is based on the principle that different molecules have different sizes and shapes. The membrane has pores of a specific size, which can allow smaller molecules (such as resveratrol) to pass through while blocking larger molecules and some impurities.3.2 Types of Membranes

- Microfiltration Membranes: These membranes have relatively large pore sizes, typically in the range of 0.1 - 10 micrometers. They are mainly used to remove larger particles and some macromolecular substances from the resveratrol - containing solution. For example, they can filter out cell debris or large protein - like substances that may be present in the extract.

- Ultrafiltration Membranes: Ultrafiltration membranes have smaller pore sizes, usually in the range of 1 - 100 nanometers. They are more effective in separating smaller macromolecules from resveratrol. For instance, they can remove some smaller peptides or polysaccharides that may still be present after the solvent extraction step.

- Nanofiltration Membranes: Nanofiltration membranes have even smaller pore sizes, which are on the order of 1 - 10 nanometers. They can further purify the resveratrol solution by selectively allowing resveratrol to pass through while retaining some smaller ionic or polar impurities.

3.3 Membrane Separation Procedure

- The resveratrol - containing solution obtained from solvent extraction is first filtered through a pre - treatment filter to remove any large particles or debris that may clog the membrane. This pre - treatment is important to ensure the smooth operation of the membrane separation process.

- The pre - filtered solution is then pumped through the selected membrane at a controlled pressure and flow rate. The pressure and flow rate need to be optimized based on the type of membrane and the characteristics of the solution. For example, for an ultrafiltration membrane, a pressure of 1 - 5 bar and a flow rate of 1 - 10 liters per hour per square meter of membrane area may be appropriate.

- The permeate (the solution that passes through the membrane) containing resveratrol is collected, while the retentate (the solution that is retained by the membrane) which contains the larger molecules and impurities is discarded.

4. Distillation

4.1 Principles of Distillation

Distillation is the final step in the extraction of high - purity resveratrol. It is based on the difference in volatility between resveratrol and any remaining volatile impurities. Resveratrol has a relatively high boiling point compared to some volatile impurities. By heating the resveratrol - containing solution under specific conditions, the volatile impurities can be vaporized and removed, leaving behind a more pure resveratrol.4.2 Types of Distillation

- Simple Distillation: Simple distillation is suitable for cases where the difference in boiling points between resveratrol and the impurities is relatively large. In this method, the resveratrol - containing solution is heated in a distillation flask. The volatile impurities with lower boiling points will vaporize first and be condensed and collected separately, while the resveratrol with a higher boiling point remains in the flask.

- Fractional Distillation: Fractional distillation is used when the difference in boiling points between resveratrol and the impurities is not so large. A fractionating column is added to the distillation setup. This column provides more separation stages, allowing for a more effective separation of resveratrol from impurities with similar boiling points.

4.3 Distillation Procedure

- The resveratrol - containing solution obtained from membrane separation is transferred to a distillation apparatus. The apparatus is carefully sealed to prevent any leakage during the distillation process.

- If simple distillation is used, the solution is heated gradually. The temperature is monitored closely, and when the volatile impurities start to vaporize (usually detected by observing the condensation in the condenser), the vapor is collected separately. If fractional distillation is used, the fractionating column is pre - heated, and the solution is then heated at a controlled rate. The different fractions are collected based on their boiling points.

- After the distillation process is completed, the high - purity resveratrol is obtained in the distillation flask or in the collected fractions, depending on the type of distillation used.

5. Conclusion

The extraction of high - purity resveratrol from resveratrol extracts is a multi - step and complex process. Starting from solvent extraction, followed by membrane separation technology, and finally distillation, each step plays a crucial role in obtaining high - purity resveratrol. High - purity resveratrol has great potential in anti - aging research, anti - cancer studies, and cardiovascular disease prevention. Therefore, continuous improvement and optimization of the extraction process are of great significance for the full utilization of resveratrol in various fields.

FAQ:

What are the main methods for extracting high - purity resveratrol from resveratrol extracts?

The main methods include solvent extraction, membrane separation technology and distillation. Solvent extraction is used first, choosing solvents that can preferentially dissolve resveratrol. Then membrane separation technology is utilized to filter out larger molecules and some impurities. Finally, distillation under specific conditions can remove remaining volatile impurities.

Why is solvent extraction important in the process of extracting high - purity resveratrol?

Solvent extraction is important because different solvents can be selected based on their ability to dissolve resveratrol preferentially. This helps to separate resveratrol from other substances in the initial extract, which is the first step towards obtaining high - purity resveratrol.

How does membrane separation technology contribute to the extraction of high - purity resveratrol?

Membrane separation technology can contribute by filtering out larger molecules and some impurities. This makes the sample closer to pure resveratrol as it helps in removing unwanted substances that are present along with resveratrol in the extract.

What role does distillation play in obtaining high - purity resveratrol?

Distillation plays a crucial role in removing any remaining volatile impurities. After solvent extraction and membrane separation, distillation under specific conditions ensures that the final product is of high purity by getting rid of any volatile substances that could still be present.

What are the potential applications of high - purity resveratrol?

High - purity resveratrol has broad prospects in anti - aging research, anti - cancer studies and cardiovascular disease prevention. It can be used in various scientific research fields to explore its effects on different biological processes and diseases.

Related literature

- Improved extraction methods for high - purity resveratrol"

- "The significance of high - purity resveratrol extraction in modern medicine"

- "Advances in the extraction process of high - purity resveratrol"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Maitake Mushroom Extract

2024-11-27

-

Genistein

2024-11-27

-

Sea buckthorn oil

2024-11-27

-

Chaste Berry Extract

2024-11-27

-

Buckthorn bark extract

2024-11-27

-

Stevia Extract

2024-11-27

-

Citrus bioflavonoids

2024-11-27

-

Uridine-5'-monophosphate Disodium salt

2024-11-27

-

Polygonum multiflorum extract

2024-11-27

-

Troxerutin

2024-11-27