- 0086-571-85302990

- sales@greenskybio.com

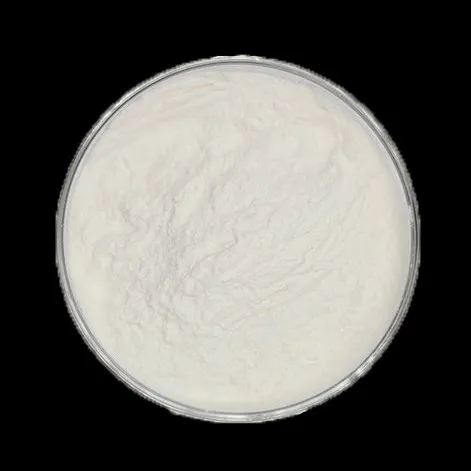

The process of extracting hydroxycitric acid from Garcinia cambogia extract.

2024-11-27

1. Introduction

Hydroxycitric acid (HCA) from Garcinia Cambogia Extract has emerged as a compound of great interest in recent years. HCA has been associated with potential benefits in weight management and overall health. The increasing demand for HCA - based products has led to a focus on the extraction process from Garcinia Cambogia Extract. This article aims to comprehensively explore the various aspects of this extraction process, including raw material preparation, extraction methods, purification, and quality control.

2. Initial raw material preparation

2.1. Source and selection of Garcinia cambogia

Garcinia cambogia is a tropical fruit - bearing tree native to Southeast Asia. When sourcing Garcinia cambogia for HCA extraction, it is crucial to select high - quality fruits. The fruits should be fully ripe, as this can affect the HCA content. Fruits that are damaged or diseased are typically avoided, as they may contain lower levels of HCA or have contaminants that could interfere with the extraction process.

2.2. Pretreatment of Garcinia cambogia fruits

Once the fruits are selected, they need to be pretreated. The first step usually involves washing the fruits thoroughly to remove any dirt, debris, or surface contaminants. After washing, the fruits are dried. Drying can be done using various methods such as sun - drying or using drying machines. Sun - drying is a traditional method that is cost - effective but may take longer and is subject to environmental factors. Drying machines can provide more controlled drying conditions, ensuring consistent quality. The dried fruits are then crushed or ground into a fine powder, which serves as the starting material for the extraction process.

3. Extraction methods

3.1. Solvent extraction

3.1.1. Choice of solvents

- One of the most common methods for extracting HCA from Garcinia Cambogia Extract is solvent extraction. The choice of solvent is critical. Ethanol is a frequently used solvent due to its relatively low toxicity and ability to dissolve HCA effectively. It also has the advantage of being relatively easy to remove during the subsequent purification steps.

- Other solvents such as water - miscible organic solvents like methanol can also be used. However, methanol is more toxic than ethanol, so extra care must be taken during handling and purification to ensure that no residual methanol remains in the final product.

The solvent extraction process is based on the principle of solubility. HCA is a polar compound, and solvents with appropriate polarity can dissolve it. When the powdered Garcinia cambogia is mixed with the solvent, the HCA molecules are transferred from the solid matrix of the powder into the solvent phase. This process is facilitated by factors such as agitation and temperature. Agitation helps to increase the contact between the solid and the solvent, allowing for more efficient extraction. Higher temperatures can also enhance the solubility of HCA in the solvent, but excessive temperatures may cause degradation of HCA or other components in the extract.

3.1.3. Extraction process steps- The powdered Garcinia cambogia is placed in a suitable extraction vessel.

- The selected solvent is added to the vessel in an appropriate ratio, typically with a solvent - to - powder ratio that ensures sufficient solvent to dissolve the HCA.

- The mixture is then agitated, either by mechanical stirring or by using a shaker, for a specific period, usually several hours to ensure complete extraction.

- After extraction, the mixture is filtered to separate the liquid extract (containing HCA dissolved in the solvent) from the solid residue.

3.2. Supercritical fluid extraction

3.2.1. Basics of supercritical fluid extraction

Supercritical fluid extraction (SFE) is another method that can be used to extract HCA from Garcinia cambogia. In this method, a supercritical fluid, often carbon dioxide (CO₂), is used as the extraction medium. A supercritical fluid is a substance that is at a temperature and pressure above its critical point, where it exhibits properties of both a gas and a liquid. CO₂ is a popular choice for SFE because it is non - toxic, non - flammable, and has a relatively low critical temperature and pressure, making it easy to handle.

3.2.2. Extraction mechanism in SFEThe extraction mechanism in SFE is different from solvent extraction. In SFE, the supercritical CO₂ penetrates the matrix of the Garcinia cambogia powder and selectively solubilizes the HCA based on its solubility in the supercritical fluid. The solubility of HCA in supercritical CO₂ can be adjusted by changing the temperature and pressure conditions. For example, increasing the pressure can generally increase the solubility of HCA in supercritical CO₂.

3.2.3. SFE process steps- The Garcinia cambogia powder is loaded into the extraction chamber of an SFE apparatus.

- The chamber is then pressurized with CO₂ to reach the supercritical state.

- The supercritical CO₂ is allowed to flow through the powder for a certain period to extract the HCA.

- Finally, the pressure is reduced, and the CO₂ returns to a gaseous state, leaving the HCA - rich extract behind.

4. Purification steps

4.1. Evaporation

After the extraction process, whether by solvent extraction or SFE, the next step is often evaporation. In the case of solvent extraction, the solvent needs to be removed to obtain a more concentrated HCA product. This is typically done by using evaporation techniques such as rotary evaporation. The liquid extract is placed in a rotary evaporator, and the solvent is evaporated under reduced pressure. This helps to lower the boiling point of the solvent, allowing for more efficient removal. The temperature during evaporation should be carefully controlled to avoid overheating and degradation of HCA.

4.2. Chromatographic purification

4.2.1. Column chromatography

Column chromatography is a commonly used method for further purifying the HCA - rich extract. A chromatography column is packed with a suitable stationary phase, such as silica gel or a resin. The extract is then loaded onto the column, and a mobile phase is passed through the column. Different components in the extract, including HCA, interact differently with the stationary and mobile phases, resulting in separation. HCA can be eluted from the column at a specific time, depending on its interaction with the column materials, and collected for further processing.

4.2.2. High - performance liquid chromatography (HPLC)HPLC is a more advanced chromatographic technique for purifying HCA. It offers higher resolution and can more accurately separate HCA from other closely related compounds. In HPLC, the extract is pumped through a column filled with a very fine - grained stationary phase at high pressure. The mobile phase composition can be precisely controlled to optimize the separation of HCA. The eluted HCA can be detected and collected with high precision, resulting in a highly purified product.

5. Quality control measures

5.1. Analysis of HCA content

One of the key quality control measures is to accurately determine the HCA content in the final product. This can be done using various analytical methods such as spectrophotometry or HPLC. Spectrophotometry can provide a quick estimate of the HCA content based on its characteristic absorption of light at a specific wavelength. HPLC, on the other hand, can provide a more accurate and detailed analysis, allowing for the quantification of HCA as well as the detection of any impurities or related compounds.

5.2. Detection of impurities

- Impurities in the HCA - rich extract can come from various sources, such as residual solvents from the extraction process, other compounds present in the Garcinia cambogia fruit, or by - products formed during extraction or purification. Detection of these impurities is essential for ensuring product quality.

- Techniques such as gas chromatography - mass spectrometry (GC - MS) can be used to detect and identify volatile impurities, especially residual solvents. For non - volatile impurities, HPLC and other chromatographic techniques can be employed to separate and detect them.

5.3. Microbiological testing

Microbiological testing is also an important part of quality control. Since Garcinia cambogia is a natural product, there is a risk of microbial contamination. Tests for bacteria, fungi, and other microorganisms are carried out to ensure that the final HCA - based product is safe for consumption. Standard microbiological testing methods, including plate count methods for total viable counts and specific tests for pathogenic microorganisms, are used.

6. Conclusion

The extraction of HCA from Garcinia cambogia extract is a complex process that involves multiple steps, from raw material preparation to purification and quality control. Each step is crucial in ensuring the production of high - quality HCA - based products. As the demand for HCA - based products continues to grow, further research and development in extraction techniques and quality control measures are likely to occur, aiming to improve efficiency, purity, and safety of these products.

FAQ:

What are the initial steps in preparing the raw material for HCA extraction from Garcinia cambogia?

The initial raw material preparation typically involves sourcing high - quality Garcinia cambogia fruits. These fruits are then cleaned to remove any dirt, debris, or impurities. After cleaning, they may be dried to reduce moisture content, which can help in subsequent extraction processes. Sometimes, the fruits are also ground or pulverized into a fine powder to increase the surface area available for extraction.

What is the solvent extraction method for HCA from Garcinia cambogia extract and how does it work?

Solvent extraction is a common method. In this process, a suitable solvent such as ethanol or water - ethanol mixtures is used. The principle behind solvent extraction is based on the solubility of HCA in the chosen solvent. The Garcinia cambogia powder (prepared from the raw material) is mixed with the solvent. The solvent penetrates the plant material and dissolves the HCA. This forms a solution containing HCA and other soluble components. Then, through filtration or centrifugation, the solid residue is separated from the solution containing the extracted HCA.

What are the purification steps to obtain high - purity HCA?

After extraction, purification steps are crucial. One common method is chromatography. For example, column chromatography can be used. The extract solution is passed through a column filled with a stationary phase. Different components in the solution, including HCA, interact differently with the stationary phase. HCA can be selectively retained and then eluted in a more purified form. Another step could be crystallization. By carefully controlling the temperature and concentration conditions, HCA can be made to crystallize out of the solution, leaving behind impurities.

What are the important quality control measures in the HCA extraction process?

Quality control measures start from the raw material inspection. The Garcinia cambogia fruits should meet certain quality standards, such as proper ripeness and absence of contaminants. During extraction, the purity and concentration of the solvent need to be monitored. After extraction and purification, the purity of HCA is determined using analytical techniques like high - performance liquid chromatography (HPLC). The final product is also checked for the presence of any residual solvents or impurities that could be harmful or affect the product's quality.

Can other extraction methods be used for HCA extraction apart from solvent extraction?

Yes, there are other methods. Supercritical fluid extraction is an alternative. In this method, a supercritical fluid, often carbon dioxide, is used as the extraction medium. Supercritical carbon dioxide has properties between those of a gas and a liquid. It can effectively extract HCA from Garcinia cambogia with some advantages over solvent extraction, such as being more environmentally friendly as it leaves no solvent residue and can be more selective in extracting specific compounds.

Related literature

- Extraction and Characterization of Hydroxycitric Acid from Garcinia cambogia"

- "Optimization of Hydroxycitric Acid Extraction from Garcinia cambogia: A Review"

- "Recent Advances in the Extraction of Hydroxycitric Acid from Garcinia cambogia for Nutraceutical Applications"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Cranberry Extract

2024-11-27

-

Hops Extract

2024-11-27

-

Agaricus Blazei Extract

2024-11-27

-

Mango flavored powder

2024-11-27

-

Honeysuckle Pollen

2024-11-27

-

Tamarind extract powder

2024-11-27

-

Lycopene

2024-11-27

-

Rosemary extract

2024-11-27

-

Cactus Extract

2024-11-27

-

Baicalin

2024-11-27