- 0086-571-85302990

- sales@greenskybio.com

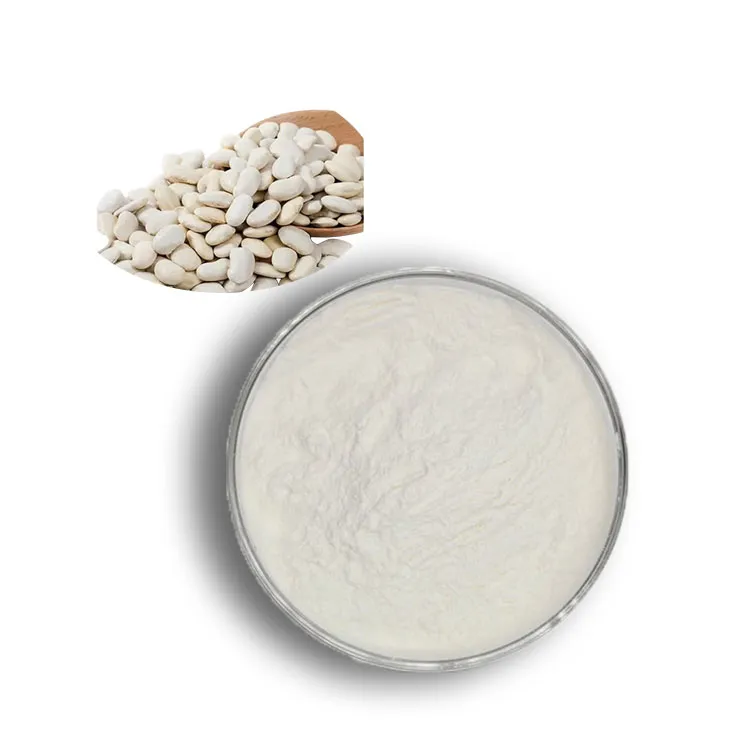

The process of extracting phaseolin from kidney bean extract.

2024-11-27

1. Introduction

Kidney beans are a widely consumed legume around the world. They are not only a rich source of nutrients but also contain various bioactive compounds. Among these, phaseolin has attracted significant attention due to its potential applications in different fields such as medicine and food science. Phaseolin is a major storage protein in kidney beans and has unique physical and chemical properties. Extracting phaseolin from Kidney Bean Extract is a complex process that involves multiple steps, each carefully designed to obtain pure phaseolin with high quality.

2. Selection of Kidney Bean Samples

2.1. Quality Considerations

The first step in the extraction of phaseolin is the careful selection of kidney bean samples.

High - quality kidney beans are essential for a successful extraction process. Quality can be determined by

several factors. Firstly, the beans should be free from physical damage, such as cracks or bruises. Damaged beans

may have undergone oxidation or microbial contamination, which can affect the quality and quantity of

phaseolin present. Secondly, the maturity of the beans is crucial. Immature beans may not have

fully developed their protein content, while over - mature beans may have started to degrade their proteins.

2.2. Source and Variety

The source of the kidney beans also plays a role. Beans sourced from reliable growers or suppliers are more

likely to be of consistent quality. Different varieties of kidney beans may have varying levels of

phaseolin. Some varieties may be genetically predisposed to have a higher content of this

protein. Therefore, choosing the right variety based on previous research or knowledge can enhance the

extraction yield. For example, certain heirloom varieties may be known to have a particularly rich

phaseolin content.

3. Preparation of Kidney Beans for Extraction

3.1. Cleaning

Once the appropriate kidney bean samples are selected, they need to be thoroughly cleaned. This is to remove any

dirt, debris, or foreign matter that may be present on the surface of the beans. The cleaning process can be as

simple as rinsing the beans under running water. However, for a more thorough cleaning, soaking the beans in

water for a short period and then gently scrubbing them can be effective.

3.2. Drying

After cleaning, the beans need to be dried. Drying is important to reduce the moisture content of the beans, as

excessive moisture can lead to spoilage during storage or affect the extraction process. The beans can be dried

naturally in a well - ventilated area or using a drying apparatus such as a low - temperature oven. The drying

temperature should be carefully controlled to avoid over - drying, which can cause the beans to become brittle

and difficult to process further.

3.3. Grinding

Grinding the dried kidney beans into a fine powder is a crucial step in the extraction process. This increases

the surface area of the beans, which in turn allows for more efficient extraction of phaseolin.

A fine powder provides more contact points for the solvent to interact with the phaseolin

molecules within the bean matrix. The grinding can be done using a mortar and pestle for small - scale

experiments or a mechanical grinder for larger - scale operations. The fineness of the powder should be

optimized, as overly fine powder may cause problems such as clogging during the extraction process.

4. Selection of Solvents for Extraction

4.1. Solvent Properties

The choice of solvent is one of the most critical aspects of the phaseolin extraction process.

The solvent should have certain properties to effectively dissolve phaseolin from the kidney

bean matrix. Firstly, it should have a good solubility for phaseolin. Different solvents have

different solubility capabilities for proteins. For example, some polar solvents like water can dissolve

hydrophilic proteins, while organic solvents may be more suitable for proteins with certain hydrophobic

regions. Secondly, the solvent should be safe to use. This is especially important if the extracted

phaseolin is intended for applications in food or medicine. Solvents that are toxic or leave

harmful residues should be avoided.

4.2. Commonly Used Solvents

There are several commonly used solvents for phaseolin extraction. One of the most popular is

water - based solvents. Water can be used alone or in combination with other substances such as salts or buffers.

Aqueous buffers can help maintain the pH of the extraction environment, which is important as the solubility

and stability of phaseolin can be affected by pH. Another option is organic solvents such as

ethanol or acetone. These solvents can be effective in extracting phaseolin, especially when

used in appropriate concentrations. However, they also pose challenges such as flammability and the need for

careful handling to ensure safety.

4.3. Solvent Mixtures

In some cases, solvent mixtures can be more effective than a single solvent. For example, a mixture of water and

ethanol can combine the advantages of both solvents. Water can provide a polar environment for dissolving the

hydrophilic parts of phaseolin, while ethanol can enhance the solubility of the hydrophobic

regions. The ratio of the solvent mixture needs to be carefully optimized based on the characteristics of the

kidney bean sample and the desired extraction efficiency.

5. The Extraction Process

5.1. Extraction Conditions

Once the solvent is selected, the extraction process can begin. The extraction conditions play a crucial role in

the efficiency of phaseolin extraction. These conditions include factors such as temperature,

extraction time, and the ratio of solvent to kidney bean powder. Temperature can significantly affect the

solubility of phaseolin. Generally, a higher temperature can increase the solubility, but

excessive heat may also cause the protein to denature. Therefore, a suitable temperature range needs to be

determined. For example, in some cases, a temperature between 40 - 60 °C may be optimal.

The extraction time also needs to be carefully controlled. Longer extraction times may lead to higher yields of

phaseolin, but it may also increase the risk of extracting other unwanted substances or cause

degradation of the phaseolin itself. A typical extraction time may range from a few hours to

overnight, depending on the specific extraction system.

The ratio of solvent to kidney bean powder is another important factor. A higher ratio of solvent may ensure

more complete extraction, but it also means a larger volume of solvent is required, which may be costly and

require more extensive purification steps later.

5.2. Stirring or Agitation

During the extraction process, stirring or agitation is often necessary. This helps to ensure that the solvent

and the kidney bean powder are well - mixed, allowing for more efficient extraction of phaseolin.

Stirring can be achieved using a magnetic stirrer in a laboratory setting or a mechanical stirrer for larger -

scale operations. The speed of stirring should be optimized to prevent excessive shearing of the protein

molecules, which could lead to denaturation.

6. Purification of Extracted Phaseolin

6.1. Filtration

After the extraction process, the resulting mixture contains not only phaseolin but also other

substances such as insoluble bean residues, solvent impurities, and possibly other proteins. Filtration is the

first step in purifying the phaseolin. Simple filtration using filter paper or a filter funnel

can remove the larger insoluble particles. For more efficient filtration, membrane filters with different pore

sizes can be used. Filtration helps to clarify the extract and separate the phaseolin - rich

solution from the solid debris.

6.2. Chromatography

Chromatography is a more advanced purification technique used to isolate pure phaseolin. There

are different types of chromatography that can be applied, such as ion - exchange chromatography, gel

filtration chromatography, and affinity chromatography.

- Ion - exchange chromatography: This method separates proteins based on their charge. Phaseolin has a specific charge at a given pH, and by using an ion - exchange resin with the opposite charge, it can be selectively bound and then eluted to obtain a purified product.

- Gel filtration chromatography: It separates proteins based on their size. Larger proteins are excluded from the pores of the gel matrix and elute first, while smaller proteins enter the pores and elute later. This can be used to separate phaseolin from other proteins of different sizes.

- Affinity chromatography: This technique utilizes the specific binding affinity of phaseolin to a particular ligand. For example, if phaseolin has a specific binding site for a certain molecule, a column with that molecule immobilized can be used to selectively bind and purify phaseolin.

7. Characterization and Quality Control of Extracted Phaseolin

7.1. Protein Characterization

Once the phaseolin is purified, it is necessary to characterize the protein to ensure its

quality and identity. Protein characterization can involve several techniques. One of the most common is

electrophoresis, such as sodium dodecyl sulfate - polyacrylamide gel electrophoresis (SDS - PAGE). This technique

can separate proteins based on their molecular weight and provide information about the purity and integrity

of the phaseolin. Another technique is mass spectrometry, which can determine the exact

molecular mass of the protein and identify any post - translational modifications.

7.2. Quality Control

Quality control is essential to ensure that the extracted phaseolin meets the required

standards for its intended applications. Quality control parameters may include the purity of the

phaseolin, which can be determined by techniques such as high - performance liquid

chromatography (HPLC). The activity of the phaseolin, if it has any specific biological

activities, should also be measured. For example, if phaseolin is being studied for its

potential antioxidant activity, appropriate assays should be carried out to determine its antioxidant

capacity.

8. Conclusion

The extraction of phaseolin from Kidney Bean Extract is a multi - step process that requires careful attention to each stage. From the selection of high - quality kidney bean samples to the final purification and quality control of the extracted phaseolin, every step is crucial in obtaining a pure and useful product. The potential applications of phaseolin in medicine and food science make this extraction process an area of great interest and importance. Continued research in this area can lead to improved extraction methods, better understanding of the properties of phaseolin, and more widespread applications of this valuable protein.

FAQ:

What are the main steps in extracting phaseolin from Kidney Bean Extract?

The main steps include carefully selecting high - quality kidney bean samples, grinding the beans into fine powder, using solvents to dissolve phaseolin out of the bean matrix, and then performing purification steps such as filtration and chromatography to isolate pure phaseolin.

Why is the choice of solvent important in the extraction of phaseolin?

The choice of solvent is important because it needs to strike a balance between effectiveness (being able to dissolve phaseolin well) and safety (not being harmful or leaving unwanted residues). A suitable solvent ensures efficient extraction of phaseolin from the kidney bean matrix.

What are the potential applications of phaseolin?

Phaseolin has potential applications in areas such as medicine and food science. In medicine, it may have certain pharmacological effects. In food science, it could be used for functional food development or food additives.

How does grinding the kidney beans into fine powder contribute to the extraction of phaseolin?

Grinding the kidney beans into fine powder maximizes the surface area available for extraction. This allows the solvent to come into more contact with the phaseolin in the bean, increasing the efficiency of the extraction process.

What purification methods are commonly used for phaseolin after extraction?

Filtration and chromatography are commonly used purification methods. Filtration can remove large particles and impurities, while chromatography helps in separating and purifying phaseolin based on its chemical properties.

Related literature

- Isolation and Characterization of Phaseolin from Different Kidney Bean Varieties"

- "Optimization of the Phaseolin Extraction Process from Kidney Beans"

- "The Role of Phaseolin in Food and Medicine: A Review"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Berberis aristata Extract

2024-11-27

-

Aguaje Extract

2024-11-27

-

Cactus Extract

2024-11-27

-

Nutmeg Extract

2024-11-27

-

Rose Hip Extract

2024-11-27

-

Black Garlic Extract

2024-11-27

-

Resveratrol extract

2024-11-27

-

Milk Thistle Extract

2024-11-27

-

Soy Extract

2024-11-27

-

Reishi mushroom extract

2024-11-27