- 0086-571-85302990

- sales@greenskybio.com

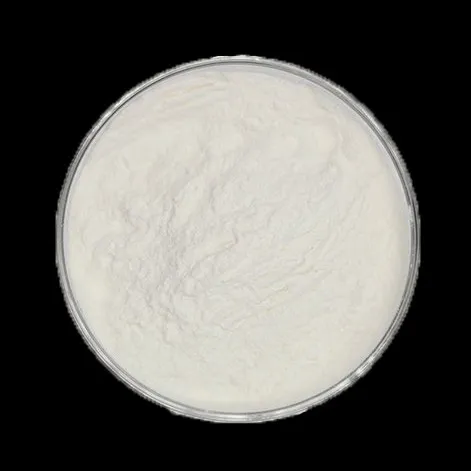

The process of extracting saw palmetto fatty acids from saw palmetto extract.

2024-11-28

1. Introduction to Saw Palmetto

Saw palmetto (Serenoa repens) is a small palm native to the southeastern United States. It has been widely recognized for its numerous health - related properties. The extract of saw palmetto is rich in various bioactive compounds, among which saw palmetto fatty acids play a crucial role. These fatty acids are of great significance in applications such as the pharmaceutical industry and dietary supplements.

2. Solvent Extraction

2.1 Choice of Solvent

One of the common methods for extracting saw palmetto fatty acids is solvent extraction. In this process, the choice of solvent is critical. Hexane is often a preferred solvent for several reasons. Hexane has a relatively low boiling point, which makes it easier to be removed from the extract after the extraction process. It also has good solubility properties for the fatty acids present in Saw Palmetto Extract. This allows for a relatively high yield of the desired fatty acids.

2.2 Extraction Procedure

The solvent extraction process typically involves the following steps:

- First, the Saw Palmetto Extract is prepared. This may involve processes such as grinding and pre - treatment to ensure better contact with the solvent.

- The extract is then mixed with the hexane solvent in an appropriate ratio. This ratio can be optimized based on experimental studies to achieve the best extraction efficiency.

- The mixture is stirred or agitated for a certain period of time. This helps in the dissolution of the fatty acids into the solvent. The extraction time can range from several hours to days depending on various factors such as the nature of the extract and the amount of solvent used.

- After the extraction, the mixture is filtered to separate the solvent - containing fatty acids from the solid residue. This solid residue may contain other components of the Saw Palmetto Extract that are not soluble in hexane.

- Finally, the solvent is evaporated to obtain the saw palmetto fatty acids. This evaporation process should be carefully controlled to avoid any degradation of the fatty acids due to excessive heat.

However, solvent extraction also has some drawbacks. The use of organic solvents like hexane poses environmental and safety concerns. There is a risk of solvent residue remaining in the final product, which may be unacceptable in some applications, especially in the production of high - quality dietary supplements or pharmaceuticals.

3. Supercritical Fluid Extraction

3.1 Principles and Advantages

Supercritical fluid extraction (SFE) is another method that has gained attention in recent years for extracting saw palmetto fatty acids. A supercritical fluid is a substance that is maintained at a temperature and pressure above its critical point. In the case of extracting saw palmetto fatty acids, carbon dioxide (CO₂) is often used as the supercritical fluid.

The main advantages of SFE are as follows:

- High Purity: Supercritical CO₂ is a relatively inert substance. It does not react with the saw palmetto fatty acids during the extraction process, which helps in obtaining a high - purity product. The absence of chemical reactions reduces the risk of introducing impurities into the final fatty acid extract.

- Environmental - friendliness: CO₂ is a non - toxic and non - flammable gas. When used as a supercritical fluid, it can be easily recycled. After the extraction, the CO₂ can be recovered and reused, reducing the environmental impact compared to traditional solvent extraction methods that use large amounts of organic solvents.

- Selectivity: The properties of supercritical CO₂ can be adjusted by changing the temperature and pressure conditions. This allows for a certain degree of selectivity in the extraction process. For example, by carefully choosing the appropriate temperature and pressure, it is possible to preferentially extract the saw palmetto fatty acids while leaving behind other unwanted components in the extract.

3.2 Key Factors in Supercritical Fluid Extraction

Several factors play important roles in the supercritical fluid extraction of saw palmetto fatty acids.

3.2.1 Temperature

Temperature has a significant impact on the extraction process. As the temperature increases, the density of the supercritical CO₂ decreases, which affects its solubility properties. At lower temperatures, supercritical CO₂ may have a higher solubility for the fatty acids, but the extraction rate may be relatively slow. On the other hand, if the temperature is too high, the selectivity of the extraction may be reduced, and there may be a risk of degrading the fatty acids.

3.2.2 Pressure

Pressure also affects the properties of supercritical CO₂. Increasing the pressure generally increases the density of the supercritical fluid, which in turn increases its solubility for the fatty acids. However, too high a pressure may require more complex and expensive equipment. Therefore, an optimal pressure needs to be determined based on factors such as the desired yield, purity, and cost - effectiveness.

3.2.3 Extraction Time

The extraction time is another important factor. Similar to solvent extraction, a longer extraction time may lead to a higher yield of fatty acids. However, there is a trade - off as an overly long extraction time may also increase the cost and may potentially lead to the extraction of unwanted components. Therefore, the extraction time needs to be optimized to balance the yield, quality, and cost.

4. Comparison of Different Extraction Methods

When comparing solvent extraction and supercritical fluid extraction for saw palmetto fatty acids, there are several aspects to consider.

4.1 Yield

Solvent extraction with hexane can often achieve a relatively high yield of saw palmetto fatty acids. However, with proper optimization of parameters such as temperature, pressure, and extraction time, supercritical fluid extraction can also obtain a satisfactory yield. In some cases, supercritical fluid extraction may even be able to selectively extract certain types of fatty acids more efficiently, resulting in a higher quality product in terms of the desired fatty acid composition.

4.2 Purity

Supercritical fluid extraction has an advantage in terms of purity. As mentioned earlier, the inert nature of supercritical CO₂ and the absence of chemical reactions during the extraction process contribute to a higher - purity product. In solvent extraction, there is a greater risk of solvent residue and potential contamination from the solvent or other components in the extract, which may require additional purification steps to achieve a similar level of purity.

4.3 Environmental and Safety Considerations

Supercritical fluid extraction using CO₂ is clearly more environmentally friendly and safer compared to solvent extraction with hexane. The use of large amounts of hexane in solvent extraction poses risks such as solvent vapor emissions, which can be harmful to the environment and human health. In contrast, CO₂ used in supercritical fluid extraction is non - toxic and can be recycled, reducing the environmental footprint.

5. Conclusion

The extraction of saw palmetto fatty acids from saw palmetto extract is an important process with potential applications in various industries. Solvent extraction, particularly using hexane, is a traditional method that can achieve a relatively high yield. However, supercritical fluid extraction, especially with CO₂, offers advantages in terms of purity, environmental - friendliness, and selectivity. The choice between the two methods depends on various factors such as the specific requirements of the end - product, cost - effectiveness, and environmental considerations. Future research may focus on further optimizing the extraction processes, exploring new solvents or supercritical fluids, and improving the overall efficiency and quality of the extraction of saw palmetto fatty acids.

FAQ:

What is saw palmetto?

Saw palmetto is a type of palm plant. It is known for its extract which contains valuable substances, especially saw palmetto fatty acids. This plant has significance in various fields, such as in traditional medicine and in the development of natural health products.

What are the common solvents used in solvent extraction of saw palmetto fatty acids?

Hexane is one of the common solvents used in solvent extraction for saw palmetto fatty acids. The choice of solvent is crucial as it can affect the yield of the extraction. Hexane is often preferred because it can effectively dissolve the fatty acids from the saw palmetto extract, resulting in a relatively high yield.

What are the advantages of supercritical fluid extraction in extracting saw palmetto fatty acids?

Supercritical fluid extraction has several advantages in extracting saw palmetto fatty acids. Firstly, it can produce a high - purity product. The process is more selective, which means it can separate the fatty acids more precisely from other components in the saw palmetto extract. Secondly, it is more environmentally - friendly compared to some traditional extraction methods. It often uses substances like carbon dioxide in a supercritical state, which is less harmful to the environment and can be easily recycled.

How does temperature affect the extraction of saw palmetto fatty acids?

Temperature plays a significant role in the extraction of saw palmetto fatty acids. Different extraction methods may have different optimal temperature ranges. In general, increasing the temperature can sometimes increase the rate of extraction as it can enhance the solubility of the fatty acids. However, if the temperature is too high, it may lead to the degradation of the fatty acids or other unwanted chemical reactions, which can affect the quality of the extracted product.

How does pressure impact the extraction of saw palmetto fatty acids?

Pressure is an important factor in the extraction of saw palmetto fatty acids, especially in methods like supercritical fluid extraction. Appropriate pressure can affect the density and solubility of the supercritical fluid, which in turn influences the extraction efficiency. If the pressure is not set correctly, it may lead to a lower yield or a product with lower purity. For example, in supercritical carbon dioxide extraction, the right pressure range needs to be maintained to ensure the optimal extraction of fatty acids.

Related literature

- Extraction of Fatty Acids from Saw Palmetto: A Comprehensive Review"

- "Saw Palmetto Extract: Optimization of Fatty Acid Extraction Processes"

- "The Role of Temperature and Pressure in Saw Palmetto Fatty Acid Extraction"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Lemon Juice Powder

2024-11-28

-

Yam Extract

2024-11-28

-

Milk Thistle Extract

2024-11-28

-

Tormentil Extract

2024-11-28

-

Hops Extract

2024-11-28

-

Genistein

2024-11-28

-

White Willow Bark Extract

2024-11-28

-

Coix Seed Extract

2024-11-28

-

Green coffee bean Extract

2024-11-28

-

Hesperidin

2024-11-28