- 0086-571-85302990

- sales@greenskybio.com

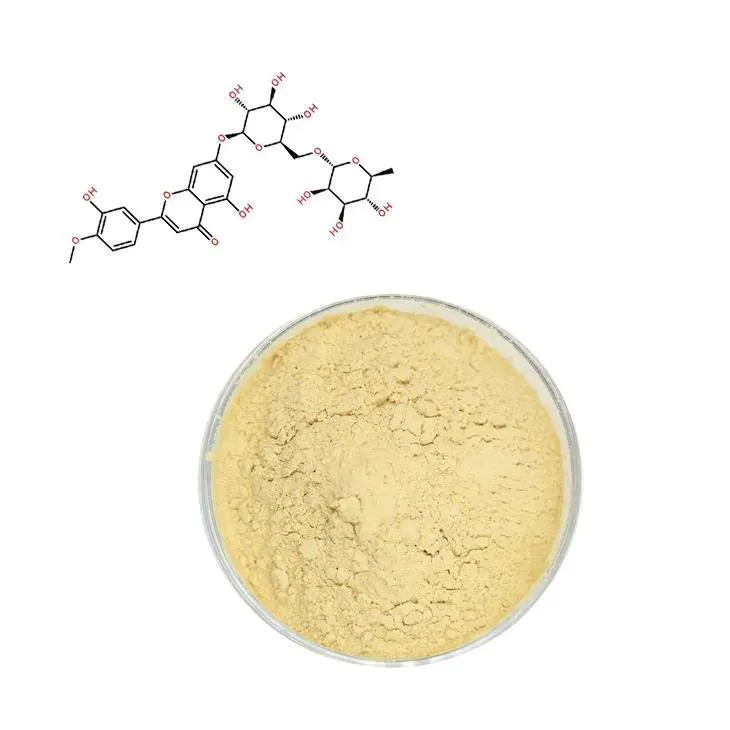

Bulk Manufacturers and Exporters of Diosmin.

2024-12-16

1. Introduction

Diosmin, a valuable bioactive compound, is an important part of the healthcare and wellness industries. It has been recognized for its various beneficial properties, making it a sought - after ingredient in different products. Understanding the manufacturers and exporters of Diosmin in bulk is essential for grasping its global market dynamics. This article will delve into the details of the production process of Diosmin by manufacturers, the role of exporters in the international market, and the significance of innovation in this context.

2. Bulk Manufacturing of Diosmin

2.1 Raw Material Sourcing

Manufacturers of diosmin in bulk are typically involved in a multi - step production process. The first step is to identify reliable sources of raw materials. There are different options for obtaining these raw materials.

- For plant - based sources, manufacturers often form partnerships with agricultural suppliers. These suppliers need to ensure a consistent supply of the plant materials from which diosmin can be extracted. For example, certain plants are rich in flavonoids, which are precursors to diosmin. The quality of these plants, including factors such as the soil conditions in which they are grown, the use of pesticides or fertilizers, and the harvesting methods, can significantly impact the quality of the resulting diosmin.

- In the case of synthetic alternatives, manufacturers may collaborate with chemical manufacturers. Synthetic production of diosmin may offer certain advantages such as a more consistent product quality and potentially a more cost - effective production process in some cases. However, it also needs to meet strict regulatory requirements regarding purity and safety.

2.2 The Manufacturing Process

Once the raw materials are in place, the manufacturing process commences. It is a complex process that often includes several key steps.

- Extraction: The process of extracting diosmin from the raw materials is crucial. Different extraction methods can be used depending on the nature of the raw materials. For plant - based materials, methods such as solvent extraction may be employed. This involves using a suitable solvent to dissolve the flavonoids containing diosmin from the plant matrix. The choice of solvent is important as it can affect the yield and purity of the extracted diosmin. For example, ethanol is a commonly used solvent in some extraction processes.

- Concentration: After extraction, the obtained solution may have a relatively low concentration of diosmin. Therefore, a concentration step is necessary. This can be achieved through techniques such as evaporation. By carefully controlling the evaporation process, the concentration of diosmin in the solution can be increased. However, it is important to note that during this process, care must be taken to avoid over - heating or other conditions that could degrade the diosmin.

- Purification: The final step in the manufacturing process is purification. This is essential to ensure that the diosmin produced meets the required purity and potency standards. Purification techniques can include chromatography methods. For example, high - performance liquid chromatography (HPLC) is commonly used to analyze and purify diosmin. HPLC allows for the separation of diosmin from other impurities based on their different chemical properties, such as polarity and molecular size. Through repeated purification steps using HPLC or other suitable methods, a high - purity diosmin product can be obtained.

2.3 Quality Control

Quality control is of utmost importance during the manufacturing processes. Manufacturers use advanced analytical techniques to ensure that the diosmin produced meets the required purity and potency standards.

- As mentioned earlier, HPLC is a key analytical tool. It can accurately determine the chemical composition of diosmin. By comparing the chromatogram of the produced diosmin with a reference standard, manufacturers can identify any impurities or deviations in the product. In addition to HPLC, other techniques such as mass spectrometry may also be used for more comprehensive analysis. Mass spectrometry can provide information about the molecular weight and structure of diosmin, which can be useful in confirming its identity and purity.

- In - process quality control checks are also carried out at different stages of the manufacturing process. For example, during the extraction step, samples may be taken to check the efficiency of the extraction and the quality of the intermediate product. Similarly, during concentration and purification, quality checks are performed to ensure that the product is on track to meet the final quality requirements.

- Batch - to - batch consistency is another important aspect of quality control. Manufacturers need to ensure that each batch of diosmin produced has the same quality characteristics. This requires strict control of the manufacturing process parameters, such as temperature, pressure, and reaction time, as well as the quality of the raw materials used. Any variation in these factors could lead to differences in the quality of the final product, which could have implications for its use in various applications.

3. Exporting of Diosmin

3.1 Understanding the Target Markets

Exporters of diosmin have the task of bridging the gap between manufacturers and international markets. They are required to have in - depth knowledge of the target markets.

- Regulatory Environment: Different countries and regions have different regulatory requirements for diosmin - based products. For example, in some European countries, there is a high demand for diosmin - based dietary supplements, but the regulations regarding their composition and labeling are very strict. Exporters need to ensure that their products are compliant with such regulations. They need to be aware of the maximum allowable levels of diosmin in products, as well as any restrictions on other ingredients that may be combined with diosmin. In addition, the labeling requirements, such as the declaration of ingredients, the recommended dosage, and any health claims, must be carefully followed.

- Consumer Preferences: Understanding consumer preferences is also crucial for exporters. In some markets, consumers may prefer diosmin - based products in a particular form, such as capsules or tablets. In other markets, there may be a preference for products with natural - sounding ingredients or those that are sourced sustainably. Exporters need to adapt their product offerings to meet these preferences. For example, if a market has a growing trend towards vegan - friendly products, exporters may need to explore options for producing diosmin - based products without using animal - derived ingredients.

- Market Competition: The diosmin market is highly competitive, both in terms of price and product quality. Exporters need to be aware of the competitive landscape in their target markets. They need to analyze the products offered by their competitors, including the price, quality, and marketing strategies. Based on this analysis, they can develop strategies to differentiate their products. For example, they may focus on offering higher - purity diosmin products at a competitive price or provide additional services such as better customer support or faster delivery.

3.2 Logistics Management

Exporters also need to be efficient in logistics management, ensuring that the diosmin reaches its destination in a timely and cost - effective manner.

- Transportation: Selecting the appropriate transportation mode is an important decision. For international shipments, options include air freight, sea freight, or a combination of both. Air freight is generally faster but more expensive, while sea freight is more cost - effective for large - volume shipments but takes longer. Exporters need to consider factors such as the urgency of the delivery, the quantity of diosmin being shipped, and the cost - benefit ratio when choosing the transportation mode.

- Packaging: Proper packaging is essential to protect the diosmin during transportation. The packaging should be designed to prevent damage from factors such as moisture, heat, and physical impact. For example, if diosmin is sensitive to moisture, it may be packaged in moisture - proof containers. In addition, the packaging should also comply with international shipping regulations, including requirements for labeling and marking.

- Documentation: Exporters need to handle all the necessary documentation accurately and efficiently. This includes documents such as commercial invoices, packing lists, certificates of origin, and any required certificates of analysis. Incorrect or incomplete documentation can lead to delays in customs clearance and potential financial losses. For example, a certificate of analysis is often required to prove the quality of the diosmin being exported, and if it is not provided or is inaccurate, the shipment may be held at customs.

4. Innovation in the Diosmin Market

In the context of the diosmin market, innovation is also a key factor for manufacturers and exporters.

- New Applications: Research into new applications of diosmin can open up new market opportunities. For example, recent research has explored the potential role of diosmin in anti - inflammation and vascular protection. If these potential applications are further validated, it could lead to an increased demand for diosmin in the pharmaceutical and nutraceutical industries. Manufacturers and exporters who can adapt to these emerging trends will be better positioned in the highly competitive global diosmin market. They can start to develop products specifically targeted at these new applications, such as formulating diosmin - based anti - inflammatory supplements or drugs for vascular health.

- Production Process Innovation: Innovation in the production process can also bring advantages. For example, the development of more efficient extraction methods can increase the yield of diosmin from raw materials, reducing production costs. New purification techniques may also improve the purity of the final product without significantly increasing the production time or cost. Manufacturers who invest in research and development to improve their production processes can gain a competitive edge in the market.

- Marketing Innovation: In addition to product and production innovation, marketing innovation is also important. Exporters and manufacturers can explore new marketing channels, such as e - commerce platforms, to reach a wider customer base. They can also use digital marketing strategies, such as social media marketing and content marketing, to raise awareness about the benefits of diosmin. For example, creating educational content about the role of diosmin in health on social media can attract potential customers and build brand loyalty.

5. Conclusion

In conclusion, the bulk manufacturing and exporting of diosmin are complex processes that involve multiple aspects. Manufacturers need to focus on raw material sourcing, a well - controlled production process, and strict quality control. Exporters need to have a deep understanding of the target markets and efficient logistics management. Innovation in various aspects, including new applications, production processes, and marketing, is crucial for both manufacturers and exporters to succeed in the highly competitive global diosmin market. As the demand for diosmin continues to grow in the healthcare and wellness industries, those involved in its production and export will need to stay updated with the latest trends and regulations to remain competitive.

FAQ:

1. What are the main steps in the bulk manufacturing process of diosmin?

The bulk manufacturing process of diosmin typically involves several steps. First, manufacturers need to identify reliable sources of raw materials, which may come from partnerships with agricultural suppliers for plant - based sources or chemical manufacturers for synthetic alternatives. Then, the manufacturing process begins, including steps like extraction, concentration, and purification. Throughout these processes, quality control is crucial, and advanced analytical techniques such as high - performance liquid chromatography (HPLC) are often used to ensure the produced diosmin meets the required purity and potency standards.

2. How do exporters of diosmin ensure compliance with different international regulations?

Exporters of diosmin need to have in - depth knowledge of the target markets' regulatory environments. For example, in some European countries where there is a high demand for diosmin - based dietary supplements but strict regulations regarding composition and labeling, exporters must study and understand these regulations thoroughly. They ensure that their products are formulated and labeled correctly to be compliant with the local requirements.

3. What role does innovation play for diosmin manufacturers and exporters?

Innovation is a key factor for diosmin manufacturers and exporters. Research into new applications of diosmin, like its potential role in anti - inflammation and vascular protection, can create new market opportunities. Manufacturers and exporters that can adapt to these emerging trends will have a competitive edge in the global diosmin market.

4. How do manufacturers ensure the quality of diosmin during production?

Manufacturers use advanced analytical techniques to ensure the quality of diosmin during production. For example, high - performance liquid chromatography (HPLC) is commonly used to analyze the chemical composition of diosmin. Quality control is of utmost importance throughout the extraction, concentration, and purification steps to ensure that the diosmin produced meets the required purity and potency standards.

5. Why is logistics management important for diosmin exporters?

Logistics management is important for diosmin exporters because they need to ensure that the diosmin reaches its destination in a timely and cost - effective manner. This helps in meeting the demands of international markets and maintaining good relationships with customers.

Related literature

- Diosmin: Properties, Applications, and Production Methods"

- "The Global Diosmin Market: Trends and Forecasts"

- "Quality Control in Diosmin Manufacturing"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Hawthorn Extract

2024-12-16

-

Milk Thistle Extract

2024-12-16

-

Hops Extract

2024-12-16

-

Gynostemma pentaphyllum extract

2024-12-16

-

Tongkat Ali Extract

2024-12-16

-

Citrus Aurantii Extract

2024-12-16

-

Senna Leaf Extract

2024-12-16

-

Apricot Powder

2024-12-16

-

Panax Ginseng Leaf Extract

2024-12-16

-

Cocoa Extract

2024-12-16