- 0086-571-85302990

- sales@greenskybio.com

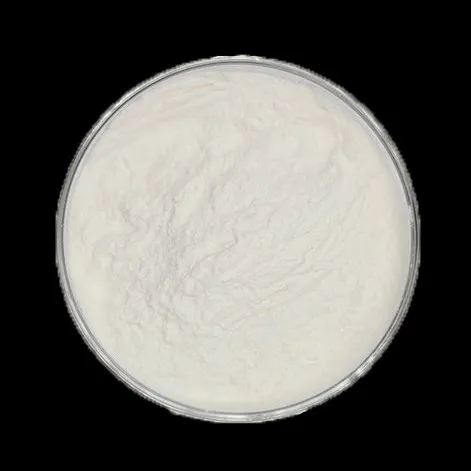

Complete Guide to Garcinia Cambogia Extract Grinding Process: Step - by - Step Key Points

2024-12-17

1. Introduction to Garcinia Cambogia Extract

Garcinia Cambogia is a tropical fruit native to Southeast Asia and India. The extract of Garcinia Cambogia has gained significant popularity in recent years, especially in the field of weight management and health supplements. It contains hydroxycitric acid (HCA), which is believed to have various beneficial effects on the body, such as suppressing appetite and inhibiting fat synthesis.

Before delving into the grinding process, it is crucial to understand the properties of the raw material. The quality of Garcinia Cambogia Extract can vary depending on factors such as the source of the fruit, the extraction method, and the purity of the extract. High - quality extracts are typically more suitable for further processing, including grinding, as they tend to have a more consistent composition and better efficacy.

2. Preparation Before Grinding

2.1. Quality Inspection

The first step in the preparation process is to conduct a thorough quality inspection of the Garcinia Cambogia Extract. This involves checking for factors such as purity, moisture content, and the presence of any contaminants.

- Purity: Ensure that the extract is free from impurities such as other plant materials or foreign substances. High - purity extracts are essential for obtaining a consistent and effective final product.

- Moisture Content: Excessive moisture can affect the grinding process and the stability of the final product. The ideal moisture content should be within a specific range, typically lower than a certain percentage (e.g., less than 10%). Measuring the moisture content can be done using specialized equipment such as a moisture analyzer.

- Contaminant Detection: Check for the presence of any contaminants, including heavy metals, pesticides, or microbial contaminants. This can be achieved through laboratory testing methods such as spectroscopy for heavy metals and microbiological assays for microbial contaminants.

2.2. Drying (if necessary)

If the moisture content of the Garcinia Cambogia extract is too high, drying may be required before grinding. Drying helps to reduce the moisture level to an acceptable range, which in turn improves the grinding efficiency and the quality of the ground product.

- There are several drying methods available, such as air drying, oven drying, and freeze - drying. Air drying is a simple and cost - effective method, but it may take a longer time. It involves spreading the extract in a well - ventilated area and allowing the moisture to evaporate naturally.

- Oven drying is a faster method, but it requires careful control of temperature and time to avoid over - drying or damaging the extract. The temperature should be set according to the characteristics of the extract, usually in the range of 40 - 60°C.

- Freeze - drying is a more advanced method that can preserve the bioactive compounds in the extract better. However, it is also more expensive and requires specialized equipment. In freeze - drying, the extract is first frozen and then the ice is removed by sublimation under vacuum conditions.

2.3. Particle Size Reduction (Optional)

Before the main grinding process, it may be beneficial to perform a preliminary particle size reduction. This can be done using methods such as crushing or milling on a coarse scale.

- Crushing can be carried out using simple tools like a mortar and pestle. This helps to break down larger chunks of the extract into smaller pieces, making it easier for subsequent grinding.

- Milling on a coarse scale can be achieved using a small - scale mill. This process can further reduce the particle size and create a more uniform starting material for the main grinding process.

3. Grinding Equipment Selection

Selecting the appropriate grinding equipment is crucial for achieving the desired particle size and quality of the Garcinia Cambogia extract powder. There are several types of grinding equipment available, each with its own advantages and limitations.

3.1. Mortar and Pestle

The mortar and pestle is a traditional and simple grinding tool. It is suitable for small - scale grinding or for obtaining a relatively coarse powder.

- Advantages: It is inexpensive, easy to use, and does not require electricity. It also allows for a certain degree of control over the grinding process, enabling the operator to adjust the grinding intensity according to the desired particle size.

- Limitations: It is time - consuming, especially for large - quantity grinding. The particle size achieved may not be as fine as that obtained using more advanced grinding equipment.

3.2. Manual Coffee Grinder

A manual coffee grinder can also be used for grinding Garcinia Cambogia extract. These grinders are designed to grind coffee beans, but they can be adapted for other materials as well.

- Advantages: They are relatively inexpensive, portable, and can produce a finer powder compared to a mortar and pestle. They also offer some control over the grinding process.

- Limitations: Similar to the mortar and pestle, they are not suitable for large - scale grinding. The grinding capacity is limited, and it may take some time to grind a significant amount of extract.

3.3. Electric Grinder

For larger - scale grinding, an electric grinder is often the preferred choice. There are different types of electric grinders, such as blade grinders and burr grinders.

- Blade Grinder: - Advantages: Blade grinders are relatively inexpensive and can quickly grind the extract into a powder. They are widely available in the market. - Limitations: They may not produce a very uniform particle size. The blades can heat up during the grinding process, which may affect the quality of the extract, especially if it contains heat - sensitive compounds.

- Burr Grinder: - Advantages: Burr grinders are more expensive but can produce a more uniform and finer powder. They work by crushing the extract between two grinding surfaces (burrs), which results in a more consistent particle size. They are also less likely to heat up the extract during grinding. - Limitations: They are more complex and require more maintenance compared to blade grinders.

3.4. Industrial - scale Grinding Equipment

In industrial settings, specialized grinding equipment such as ball mills, hammer mills, or roller mills may be used for large - volume production of Garcinia Cambogia extract powder.

- Ball Mill: - Advantages: Ball mills are capable of grinding large quantities of extract to a very fine powder. They work by rotating a cylinder containing balls (usually made of steel or ceramic), which crush and grind the material. They can achieve a high degree of fineness and uniformity in the particle size. - Limitations: They are expensive, require a large amount of space, and consume a significant amount of energy.

- Hammer Mill: - Advantages: Hammer mills are efficient for reducing the particle size of the extract. They use high - speed rotating hammers to impact and break the material into smaller pieces. They are relatively inexpensive and can handle a large throughput. - Limitations: They may produce a wider range of particle sizes compared to ball mills, and the powder may not be as fine.

- Roller Mill: - Advantages: Roller mills are good for achieving a consistent particle size. They work by passing the material between two or more rollers, which compress and grind it. They are often used in continuous production processes. - Limitations: They are not as effective for grinding very hard materials, and they may require more precise adjustment compared to other industrial - scale grinders.

4. The Grinding Process

4.1. Mortar and Pestle Grinding

If using a mortar and pestle, place a small amount of the prepared Garcinia Cambogia extract in the mortar. Hold the pestle firmly and begin to grind the extract in a circular motion.

- Start with gentle pressure and gradually increase the force as the extract begins to break down. This helps to avoid splashing the extract out of the mortar.

- Continue grinding until the desired particle size is achieved. This may take several minutes to half an hour or more, depending on the quantity of extract and the desired fineness.

4.2. Manual Coffee Grinder Grinding

For a manual coffee grinder, first, adjust the grinder settings if possible to a relatively fine setting. Then, place the Garcinia Cambogia extract into the grinder's hopper.

- Turn the grinder handle slowly and steadily. The extract will be gradually ground between the grinder's components.

- Monitor the grinding progress by occasionally checking the particle size of the emerging powder. Stop grinding when the desired fineness is reached.

4.3. Electric Grinder Grinding

When using an electric grinder, whether it is a blade grinder or a burr grinder, follow the manufacturer's instructions for operation.

- For a blade grinder, place the extract into the grinder's container. Secure the lid and turn on the grinder. Run the grinder for short intervals (e.g., 10 - 15 seconds) and then stop to check the particle size. Repeat this process until the desired powder is obtained. This helps to prevent over - grinding and overheating.

- For a burr grinder, load the extract into the grinder according to the instructions. Set the appropriate grinding settings for the desired particle size. Start the grinder and let it run until the extraction is completely ground. Since burr grinders are less likely to overheat, they can usually be run continuously for a longer period compared to blade grinders.

4.4. Industrial - scale Grinding

In industrial - scale grinding, the process is more complex and typically automated.

- For a ball mill, the Garcinia Cambogia extract is loaded into the mill along with the grinding balls. The mill is then set to rotate at a specific speed for a predetermined period. The rotation of the mill causes the balls to collide with the extract, grinding it into a fine powder. During the process, parameters such as the speed of rotation, the ratio of balls to extract, and the grinding time need to be carefully controlled to ensure the quality of the final product.

- In a hammer mill, the extract is fed into the mill through a hopper. The high - speed rotating hammers impact the extract, breaking it into smaller particles. The size of the hammers, the speed of rotation, and the feed rate of the extract need to be adjusted according to the desired particle size and production capacity.

- For a roller mill, the extract is passed between the rollers. The gap between the rollers and the speed at which they rotate are adjusted to control the particle size of the ground product. Continuous monitoring and adjustment are often required in industrial - scale roller mill operations to maintain consistent product quality.

5. Post - Grinding Processing

5.1. Sifting

After grinding, it is often necessary to sift the powder to remove any large particles or unground fragments. Sifting can be done using a sieve with an appropriate mesh size.

- The choice of sieve mesh size depends on the desired fineness of the final product. For example, a finer mesh sieve will be used if a very fine powder is required.

- Sifting not only improves the quality of the powder but also ensures the uniformity of the particle size, which is important for applications such as formulating supplements or creating cosmetic products.

5.2. Packaging

Once the sifted powder is obtained, it is ready for packaging. The choice of packaging material depends on factors such as the stability of the Garcinia Cambogia extract, the intended shelf - life, and the storage conditions.

- For short - term storage or immediate use, simple plastic bags or containers may be sufficient. However, for long - term storage, it is advisable to use air - tight, light - resistant, and moisture - resistant packaging such as foil - lined bags or amber - colored glass bottles.

- Proper packaging helps to protect the extract powder from environmental factors such as air, moisture, and light, which can degrade the quality of the extract over time.

5.3. Quality Control and Testing

After packaging, quality control and testing should be carried out to ensure that the final product meets the required standards.

- This may include testing for factors such as particle size distribution, purity, and the content of active ingredients (such as HCA). Laboratory techniques such as particle size analysis using laser diffraction, chromatographic methods for purity and active ingredient analysis may be employed.

- If the product does not meet the standards, appropriate corrective actions need to be taken, such as re - grinding, adjusting the packaging, or improving the quality control procedures in the previous steps.

6. Conclusion

The grinding process of Garcinia Cambogia extract is a multi - step process that requires careful attention to detail at each stage. From the initial preparation of the extract, through the selection of appropriate grinding equipment, to the post - grinding processing and quality control, every step plays a crucial role in obtaining a high - quality final product.

Whether it is for small - scale personal use or large - scale industrial production, following the proper grinding process guidelines can ensure that the Garcinia Cambogia extract powder is of consistent quality, which is essential for its effectiveness in various applications such as weight management and health supplements.

FAQ:

Question 1: What is Garcinia Cambogia extract?

Garcinia Cambogia extract is a substance derived from the fruit of the Garcinia Cambogia tree. It contains hydroxycitric acid (HCA), which is believed to have various potential health benefits, such as appetite suppression and aiding in weight management.

Question 2: Why is the grinding process important for Garcinia Cambogia extract?

The grinding process is crucial as it helps to break down the Garcinia Cambogia material into a more fine and consistent form. This can enhance the extraction efficiency of the active compounds, improve solubility, and make it more suitable for various applications, such as in dietary supplements or pharmaceutical preparations.

Question 3: What are the initial steps in the Garcinia Cambogia extract grinding process?

First, the Garcinia Cambogia fruits need to be sourced and carefully selected to ensure their quality. Then, they are typically dried to reduce moisture content. After drying, the fruits may be pre - processed, such as removing any impurities or unwanted parts.

Question 4: What equipment is commonly used in the grinding process of Garcinia Cambogia extract?

Commonly used equipment includes grinding mills, such as ball mills or hammer mills. These mills can effectively break down the dried Garcinia Cambogia material into a powder form. Additionally, sieves may be used to ensure the uniformity of the particle size of the ground extract.

Question 5: How can the quality of the ground Garcinia Cambogia extract be ensured?

To ensure quality, strict quality control measures should be implemented throughout the grinding process. This includes regular inspection of the equipment to ensure proper functioning, monitoring the particle size distribution, and testing for the presence and concentration of the active compounds. Also, following good manufacturing practices (GMP) helps to maintain the overall quality of the ground extract.

Related literature

- The Chemistry and Pharmacology of Garcinia Cambogia Extract"

- "Optimization of Garcinia Cambogia Extract Production: A Review"

- "Garcinia Cambogia: From Fruit to Extract - Processing and Quality Control"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Scutellaria Extract

2024-12-17

-

Mango flavored powder

2024-12-17

-

Golden Seal Extract

2024-12-17

-

Curcumin Extract

2024-12-17

-

Peppermint Oil

2024-12-17

-

Calendula Extract

2024-12-17

-

Polygonum Cuspidatum Extract

2024-12-17

-

Elderberry Extract

2024-12-17

-

Camu Camu Extract

2024-12-17

-

Purple Sweet Potato Extract

2024-12-17