- 0086-571-85302990

- sales@greenskybio.com

How do manufacturers of Diosmin wholesale and customize products?

2024-12-12

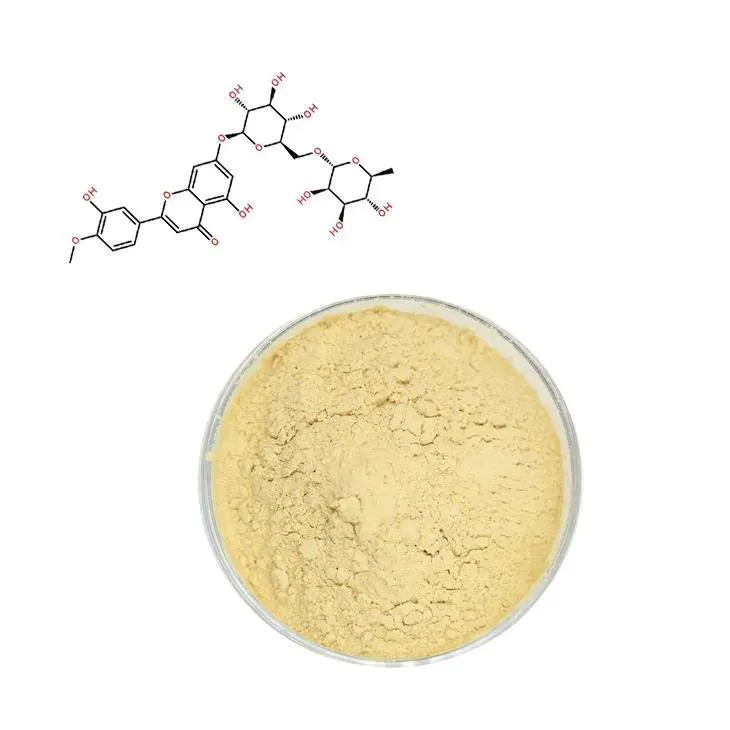

1. Introduction to Diosmin

Diosmin is a flavonoid with significant health - related properties. It has been widely used in the pharmaceutical and nutraceutical industries. Diosmin is known for its potential benefits in improving vascular health, reducing inflammation, and enhancing blood circulation. Given its importance, the manufacturing and distribution of Diosmin products are crucial aspects of the industry.

2. Wholesale Operations of Diosmin Manufacturers

2.1 Inventory Management

Inventory management is a vital part of Diosmin wholesale. Manufacturers need to carefully balance their inventory levels. Maintaining too much inventory can tie up capital and increase storage costs. On the other hand, insufficient inventory may lead to missed sales opportunities due to an inability to meet market demand during fluctuations.

Manufacturers often use advanced inventory management systems. These systems can track inventory levels in real - time, predict future demand based on historical data, and generate alerts when inventory reaches a certain threshold. For example, during the peak season of Diosmin sales, which may be influenced by factors such as health awareness campaigns or seasonal health trends, manufacturers need to ensure that they have enough stock to supply to their wholesale partners.

2.2 Product Information and Support

Another important aspect of wholesale operations is providing product information and support to partners. Diosmin manufacturers should offer comprehensive product details, including information about its composition, manufacturing process, quality control measures, and potential health benefits.

Manufacturers can provide technical support to their wholesale partners. This may include answering questions about product usage, storage conditions, and handling procedures. For instance, if a wholesale partner has questions about the stability of Diosmin products under different environmental conditions, the manufacturer should be able to provide accurate and timely answers.

Marketing support is also crucial. Manufacturers can supply marketing materials such as brochures, product datasheets, and promotional posters to help their wholesale partners promote Diosmin products more effectively. These materials should highlight the unique selling points of Diosmin, such as its high - quality ingredients, scientific research - backed benefits, and compliance with regulatory standards.

3. Customization Operations of Diosmin Manufacturers

3.1 Ingredient - based Customization

Manufacturers can offer customization based on ingredient combinations. In the context of Diosmin, they can develop products with unique ingredient profiles for specific health conditions. For example, for customers who are mainly concerned about vascular health, manufacturers can create Diosmin products combined with other ingredients like Hesperidin, which has complementary effects on blood vessel protection.

Customizing ingredient combinations also allows manufacturers to target different consumer segments. For the elderly market, a Diosmin product may be customized with additional nutrients like vitamin D and calcium to support overall bone and vascular health. This kind of customization not only meets the specific health needs of consumers but also gives manufacturers a competitive edge in the market.

3.2 Release Mechanism Customization

Another form of customization is related to the release mechanism of Diosmin products. Different release mechanisms can affect the absorption and efficacy of Diosmin in the body.

Manufacturers can develop products with sustained - release or controlled - release mechanisms. A sustained - release Diosmin product can release the active ingredient slowly over an extended period, providing a more continuous therapeutic effect. This is beneficial for patients who need long - term treatment for chronic vascular diseases. On the other hand, a controlled - release mechanism can be designed to release Diosmin at a specific rate based on factors such as the body's circadian rhythm or the progression of a disease.

Customizing the release mechanism also allows manufacturers to differentiate their products from competitors. For example, a new - to - market Diosmin product with an innovative release mechanism may attract more attention from consumers and healthcare professionals alike.

4. Challenges in Wholesale and Customization

4.1 Regulatory Compliance

The Diosmin manufacturing industry is highly regulated. In both wholesale and customization operations, manufacturers must ensure that their products comply with relevant regulatory standards. This includes meeting quality control requirements, proper labeling, and following safety regulations.

For wholesale, products need to be properly labeled with accurate ingredient information, dosage instructions, and warnings. In customization, especially when developing new ingredient combinations or release mechanisms, manufacturers may need to go through additional regulatory approvals. For example, if a manufacturer wants to introduce a Diosmin product with a new combination of ingredients not previously approved, they may need to conduct extensive safety and efficacy studies and submit the results to regulatory authorities for review.

4.2 Cost Management

Cost management is a significant challenge in both wholesale and customization. In wholesale, manufacturers need to balance the cost of production, inventory, and distribution to ensure profitability. High production costs can lead to higher wholesale prices, which may make their products less competitive in the market.

In customization, developing unique products often incurs additional costs. These costs may include research and development expenses for new ingredient combinations or release mechanisms, as well as the cost of setting up specialized production lines. Manufacturers need to find ways to manage these costs without sacrificing product quality or customization capabilities.

5. Strategies for Success in Wholesale and Customization

5.1 Quality Assurance

Quality assurance is a fundamental strategy for success. Manufacturers should implement strict quality control measures throughout the production process. This includes sourcing high - quality raw materials, using advanced manufacturing techniques, and conducting regular product testing.

In wholesale, providing consistent, high - quality Diosmin products helps build trust with wholesale partners and end - consumers. In customization, quality assurance is even more critical as customized products are often targeted at specific consumer needs. Any quality issues in customized products can lead to negative impacts on both the manufacturer's reputation and the health of consumers.

5.2 Market Research

Market research is essential for understanding customer needs and market trends. In wholesale, manufacturers can use market research to identify potential wholesale partners, determine optimal pricing strategies, and forecast market demand.

In customization, market research helps manufacturers identify emerging consumer needs and preferences for customized Diosmin products. For example, research may show that there is an increasing demand for Diosmin products with natural ingredients among health - conscious consumers. Manufacturers can then use this information to develop customized products that meet this demand.

5.3 Collaboration

Collaboration is another important strategy. In wholesale, manufacturers can collaborate with their wholesale partners to optimize inventory management, share marketing resources, and jointly develop new markets.

In customization, manufacturers can collaborate with research institutions, healthcare providers, or other industry players. For example, collaborating with research institutions can help manufacturers stay updated on the latest scientific research related to Diosmin and develop more effective customized products. Collaborating with healthcare providers can provide insights into the clinical needs of patients and improve the customization of Diosmin products for medical use.

6. Conclusion

The wholesale and customization operations of Diosmin manufacturers are complex and challenging, but also full of opportunities. By effectively managing inventory, providing product information and support in wholesale, and offering value - added customization services, manufacturers can meet the diverse needs of the market.

However, they also need to overcome challenges such as regulatory compliance and cost management. Through strategies like quality assurance, market research, and collaboration, Diosmin manufacturers can enhance their competitiveness and succeed in the dynamic Diosmin market.

FAQ:

What are the key factors in Diosmin wholesale inventory management?

Key factors in Diosmin wholesale inventory management include accurately predicting market demand. Manufacturers need to analyze historical sales data, market trends, and factors such as seasonality. They also need to consider the lead time for production and supply. If the lead time is long, they may need to maintain a relatively higher inventory level. Additionally, cooperation with suppliers is important. Stable and reliable suppliers can help ensure a continuous supply of raw materials, reducing the risk of inventory shortages.

How do Diosmin manufacturers support their wholesale partners?

Diosmin manufacturers can support their wholesale partners in several ways. They can provide detailed product information, including product features, usage instructions, and quality certifications. Technical support may also be offered, such as answering questions about product compatibility or potential applications. Marketing support is another aspect, for example, providing promotional materials or sharing market insights to help wholesale partners better promote Diosmin products.

What are the challenges in customizing Diosmin products?

One challenge in customizing Diosmin products is ensuring regulatory compliance. Different regions may have different regulations regarding the composition, dosage, and labeling of health - related products. Another challenge is the R & D cost and time. Developing customized products with unique ingredients or release mechanisms often requires significant investment in research and development. There may also be challenges in production scale - up. Ensuring consistent quality and cost - effectiveness when producing customized batches can be difficult.

How can Diosmin manufacturers ensure the quality of customized products?

To ensure the quality of customized Diosmin products, manufacturers should start with strict raw material selection. They need to source high - quality raw materials from reliable suppliers. In the production process, strict quality control procedures should be implemented, including regular inspections and testing at different production stages. For customized products, additional verification may be required to ensure that the unique features or combinations meet the expected quality standards. Documentation of the entire production process is also crucial for traceability and quality assurance.

What are the benefits of Diosmin product customization for customers?

For customers, Diosmin product customization offers several benefits. It allows them to get products that are more tailored to their specific health needs. For example, those with certain chronic conditions can get Diosmin products with specific ingredient combinations. Customized products may also offer more convenient usage forms or release mechanisms. This can improve patient compliance and the effectiveness of the product in addressing their health concerns.

Related literature

- Diosmin: Properties, Applications and Manufacturing"

- "Wholesale Strategies in the Diosmin Industry"

- "Customization in Dietary Supplement Manufacturing: The Case of Diosmin"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Natural grape seed extract

2024-12-12

-

Green Tea Extract

2024-12-12

-

Bitter Melon Extract

2024-12-12

-

melatonin extract

2024-12-12

-

Sea buckthorn Juice Powder

2024-12-12

-

Andrographis Paniculata Extract Powder

2024-12-12

-

Cactus Extract

2024-12-12

-

Yohimbine Bark Extract

2024-12-12

-

Peppermint Extract Powder

2024-12-12

-

Shikonin

2024-12-12