- 0086-571-85302990

- sales@greenskybio.com

Only cooperate with the best contract manufacturers of resveratrol extract.

2024-12-13

1. Introduction

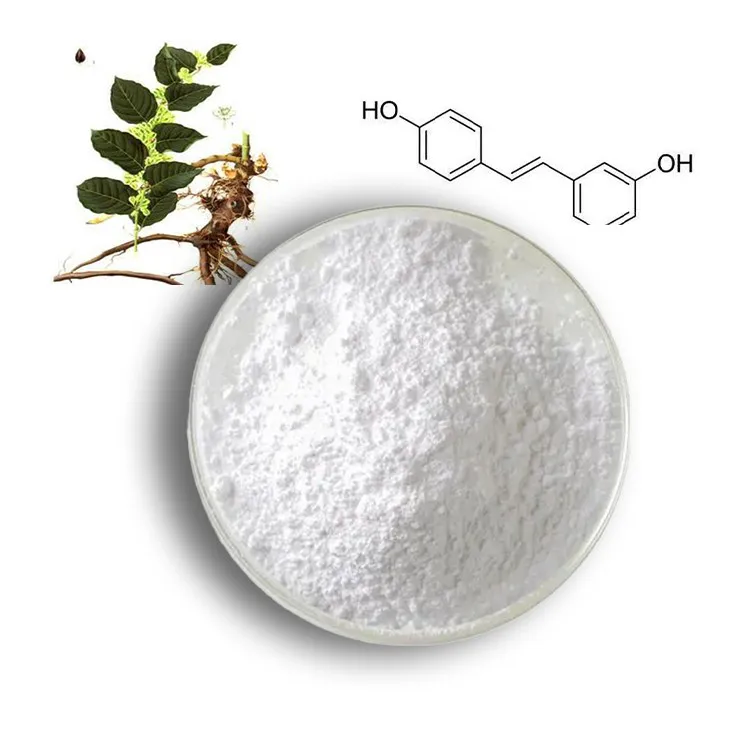

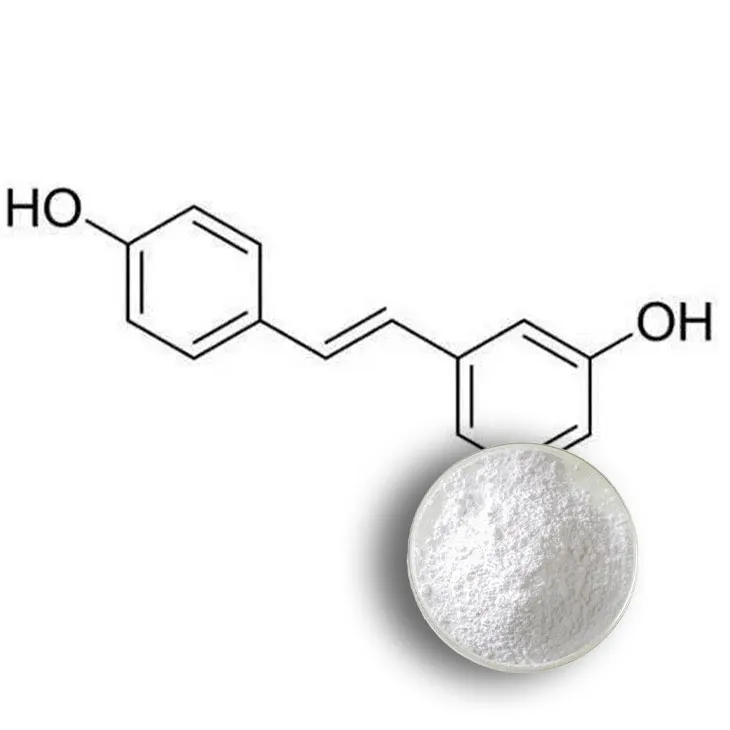

Resveratrol extract has emerged as a highly desirable ingredient in the realm of health products. Its potential health benefits, such as antioxidant properties and possible anti - aging effects, have led to its widespread inclusion in various supplements, nutraceuticals, and even some cosmetic products. However, the quality of Resveratrol extract can vary significantly depending on the manufacturing process. For businesses involved in the production or marketing of products containing resveratrol, selecting the right contract manufacturer is of utmost importance.

2. Importance of High - Quality Resveratrol extracts

High - quality resveratrol extracts are not only more effective in delivering the desired health benefits but also contribute to the overall reputation of the product. Consumers are becoming increasingly educated about the ingredients in the products they use, and they expect a certain level of quality. If a product contains sub - par resveratrol extract, it may not only fail to provide the expected benefits but also lead to negative customer reviews and a damaged brand image.

3. Sophisticated Manufacturing Processes

3.1. Extraction Methods

The best contract manufacturers employ advanced extraction methods for resveratrol. There are several methods available, such as solvent extraction, supercritical fluid extraction, and enzymatic extraction. Solvent extraction is a common method, but it requires careful selection of solvents to ensure purity. For example, some solvents may leave behind residues that can be harmful or affect the quality of the extract. Supercritical fluid extraction, on the other hand, uses substances like carbon dioxide in a supercritical state. This method has the advantage of being more environmentally friendly and can often result in a purer extract with a higher concentration of resveratrol. Enzymatic extraction is also gaining popularity as it can be more selective in extracting resveratrol from the source material, which may be grapes, berries, or other plants.

3.2. Purification Steps

After extraction, purification is a crucial step. High - quality contract manufacturers will have multiple purification steps in place. This may include filtration processes to remove solid impurities, chromatography techniques to separate different components, and crystallization to obtain a pure form of resveratrol. These purification steps help to ensure that the final extract has a high concentration of resveratrol and minimal impurities, which is essential for its effectiveness in health products.

4. State - of - the - Art Facilities

The premier resveratrol extract contract manufacturers are well - equipped with state - of - the - art facilities. These facilities play a vital role in the production of high - quality extracts. For instance, they have advanced laboratory equipment for quality control and research. They also have large - scale production equipment that is designed to handle the extraction and purification processes efficiently. The facilities are often maintained at optimal environmental conditions, such as controlled temperature and humidity, to ensure the stability of the resveratrol during production. Additionally, modern facilities are likely to have automated processes, which not only increase productivity but also reduce the risk of human error in the manufacturing process.

5. Regulatory Compliance

Regulatory compliance is a non - negotiable aspect when it comes to resveratrol extract manufacturing. Different regions have different regulations regarding the production, labeling, and marketing of products containing resveratrol. The top manufacturers stay updated with these regulations. For example, in the United States, the Food and Drug Administration (FDA) has certain guidelines for dietary supplements. Manufacturers need to ensure that their resveratrol extracts meet the purity, safety, and labeling requirements set by the FDA. In the European Union, similar regulations exist under the European Food Safety Authority (EFSA). Manufacturers must also be aware of any changes in these regulations over time and adapt their production processes accordingly. This ensures that the products can be legally marketed both domestically and internationally without any legal hindrances.

6. Innovation in Resveratrol Extract Manufacturing

Leading contract manufacturers are at the forefront of innovation in resveratrol extract manufacturing. They are constantly looking for ways to improve the quality and properties of the extract.

6.1. New Formulations

One way they innovate is through the development of new formulations. For example, they may create a time - released formulation of resveratrol extract, which allows for a slow and sustained release of the active ingredient in the body. This can potentially enhance its effectiveness as it provides a more consistent level of resveratrol in the bloodstream over a longer period. Another innovation could be in the form of microencapsulation, where the resveratrol is encapsulated in small particles. This can protect the resveratrol from degradation during storage or in the digestive system, ensuring that it reaches the target site in the body intact.

6.2. Combinations with Other Ingredients

Manufacturers also explore combinations with other beneficial ingredients. Resveratrol may be combined with other antioxidants like vitamin C or E to create a more potent antioxidant blend. It could also be combined with ingredients that enhance its absorption in the body, such as certain lipids or peptides. These combinations not only open up new market opportunities for their partners but also provide consumers with more comprehensive and effective health products.

7. Quality Control and Assurance

Quality control and assurance are integral parts of the manufacturing process for resveratrol extracts. The best contract manufacturers have strict quality control measures in place at every stage of production.

7.1. Raw Material Testing

Before starting the extraction process, they test the raw materials thoroughly. This includes checking for the presence of contaminants, verifying the authenticity of the source material (for example, ensuring that the grapes used for resveratrol extraction are of the correct variety and quality), and determining the initial concentration of resveratrol in the raw material. Only high - quality raw materials are selected for the extraction process.

7.2. In - Process Monitoring

During the extraction and purification processes, continuous monitoring is carried out. Parameters such as temperature, pressure, and extraction time are closely monitored to ensure that the processes are proceeding as expected. Any deviations from the set parameters can be immediately corrected to prevent the production of sub - standard extracts.

7.3. Final Product Testing

Once the resveratrol extract is produced, it undergoes comprehensive final product testing. This includes tests for purity, potency, and stability. The extract is also tested for any potential allergens or harmful substances. Only products that pass all these tests are released for packaging and distribution.

8. Conclusion

In conclusion, when it comes to resveratrol extract, partnering with the best contract manufacturers is crucial for businesses in the health product industry. These manufacturers are distinguished by their use of sophisticated manufacturing processes, state - of - the - art facilities, regulatory compliance, innovation, and strict quality control measures. By choosing the premier contract manufacturers, businesses can ensure that they are getting high - quality resveratrol extracts for their products, which in turn can lead to customer satisfaction, a positive brand image, and success in the highly competitive health product market.

FAQ:

Q1: What are the key factors to consider when choosing a resveratrol extract contract manufacturer?

When choosing a resveratrol extract contract manufacturer, several key factors need to be considered. Firstly, production capabilities are crucial. The manufacturer should be well - equipped with advanced facilities to ensure high - precision production and minimal impurities in the resveratrol extracts. Secondly, regulatory compliance is non - negotiable. They must stay updated with the latest regulations regarding resveratrol extraction and product formulation to ensure legal compliance of the products. Thirdly, innovation is also important. A good contract manufacturer should be constantly seeking ways to enhance the properties of resveratrol extracts, such as developing new formulations or combinations with other beneficial ingredients.

Q2: How can one ensure that a resveratrol extract contract manufacturer is of high quality?

To ensure a resveratrol extract contract manufacturer is of high quality, one can look at their production facilities. State - of - the - art facilities are often an indication of their ability to produce high - quality extracts. Also, check their compliance with regulations. A manufacturer that is up - to - date with all relevant regulations is more likely to produce reliable products. Additionally, their history of innovation can be a sign of high quality. If they have a track record of developing new and improved resveratrol - related products, it shows their commitment to quality and advancement in the field.

Q3: Why is regulatory compliance important for resveratrol extract contract manufacturers?

Regulatory compliance is extremely important for resveratrol extract contract manufacturers. Firstly, it ensures that the products they produce are legally compliant. This means that the products can be marketed without facing legal issues or hindrances. Secondly, compliance with regulations regarding resveratrol extraction and product formulation also indicates that the manufacturer is following proper safety and quality standards. This protects the end - users of the products and also helps to build a good reputation for the manufacturer and its partners in the market.

Q4: What role does innovation play in resveratrol extract contract manufacturing?

Innovation plays a significant role in resveratrol extract contract manufacturing. It allows manufacturers to enhance the properties of resveratrol extracts. For example, they may develop new formulations that improve the bioavailability or effectiveness of the resveratrol. Innovations can also involve combining resveratrol with other beneficial ingredients, which can open up new market opportunities. By being innovative, contract manufacturers can stay competitive in the market and offer unique products to their partners.

Q5: How do the best resveratrol extract contract manufacturers ensure high - precision production?

The best resveratrol extract contract manufacturers ensure high - precision production through their state - of - the - art facilities. These facilities are equipped with advanced technology and machinery that can accurately control the extraction process. They also have strict quality control measures in place. Skilled technicians and scientists are involved in the production process to monitor and adjust the parameters as needed. Additionally, they may use high - quality raw materials and follow standardized production protocols to achieve high - precision production of resveratrol extracts.

Related literature

- The Production and Quality Control of Resveratrol Extracts"

- "Innovations in Resveratrol Extraction Technologies"

- "Regulatory Aspects of Resveratrol - Based Health Products"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Purple Sweet Potato Extract

2024-12-13

-

Citrus Aurantium Extract

2024-12-13

-

Licorice Root Extract Powder

2024-12-13

-

Lavender Extract

2024-12-13

-

Shikonin

2024-12-13

-

Cassia Seed Extract

2024-12-13

-

Eyebright Extract

2024-12-13

-

Withania Somnifera Extract

2024-12-13

-

Saw Palmetto Extract

2024-12-13

-

Beta Carotene

2024-12-13