- 0086-571-85302990

- sales@greenskybio.com

Reliability and Efficiency: Pillars for Top Resveratrol Extract Manufacturers to Provide Effective Products.

2024-12-18

1. Introduction

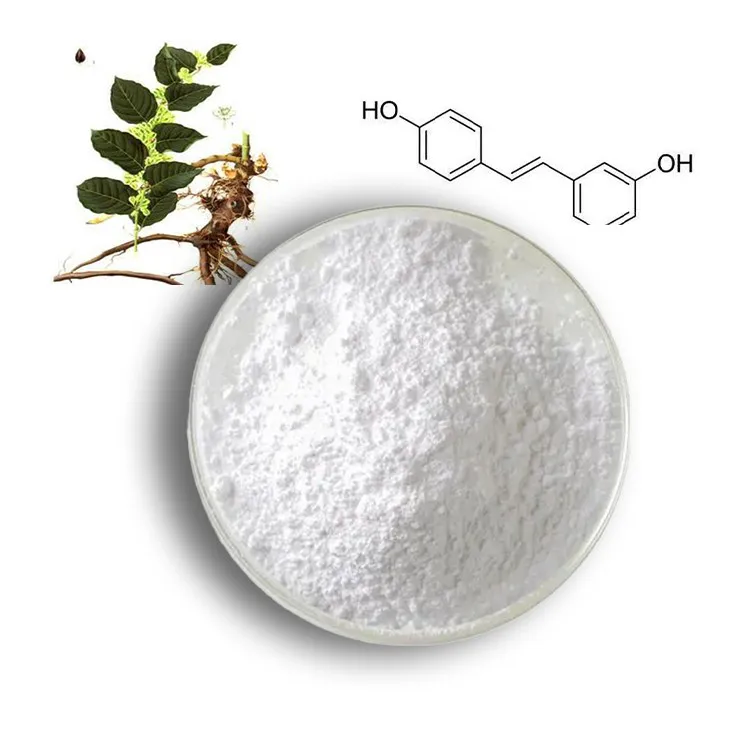

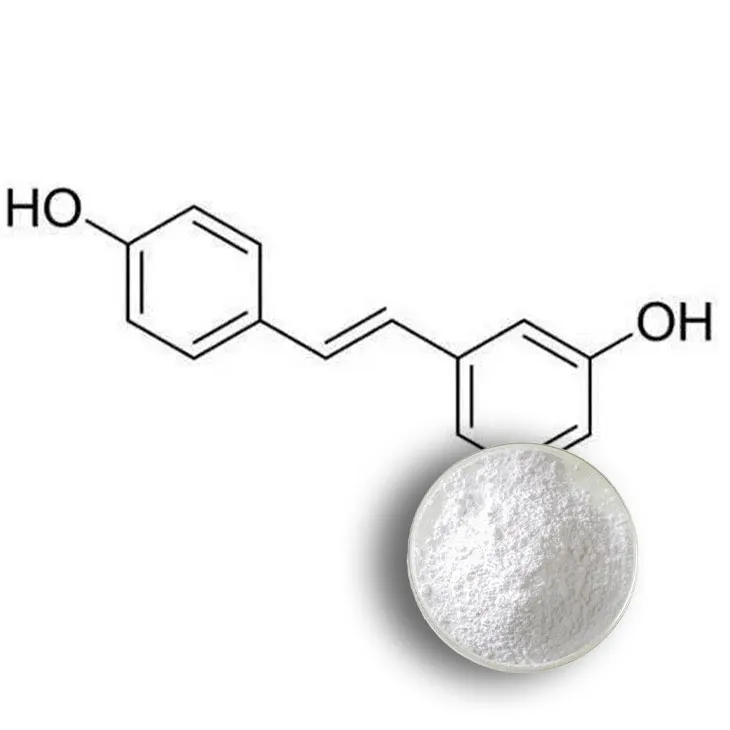

Resveratrol has gained significant attention in recent years due to its potential health benefits. As a compound found in various plants, particularly in grapes and red wine, it has been associated with antioxidant, anti - inflammatory, and anti - aging properties. For consumers, the demand for high - quality resveratrol - based products is on the rise. However, the effectiveness of these products largely depends on the manufacturers. In this regard, reliability and efficiency stand as two crucial pillars for top Resveratrol extract manufacturers to deliver effective products.

2. The Significance of Resveratrol

2.1. Antioxidant Properties

Resveratrol is known for its strong antioxidant capabilities. It can scavenge free radicals in the body, which are unstable molecules that can cause damage to cells, DNA, and proteins. By neutralizing these free radicals, resveratrol helps to protect the body from oxidative stress, which is linked to various diseases such as cancer, heart disease, and neurodegenerative disorders.2.2. Anti - Inflammatory Effects

Chronic inflammation is a common factor in many health problems. Resveratrol has been shown to modulate the body's inflammatory response. It can inhibit the production of pro - inflammatory cytokines and enzymes, thereby reducing inflammation. This anti - inflammatory property makes it potentially useful in treating conditions like arthritis, inflammatory bowel disease, and skin inflammations.2.3. Anti - Aging Potential

Resveratrol may play a role in the anti - aging process. It has been found to activate certain genes related to longevity in some organisms. Additionally, its antioxidant and anti - inflammatory effects contribute to maintaining the health and function of cells, which can slow down the aging process at the cellular level.

3. Reliability in Resveratrol extract Manufacturing

3.1. Consistent Quality

- Top Resveratrol extract manufacturers must ensure that the quality of their products remains consistent from batch to batch. This requires strict control over the raw materials used. For example, the source of grapes or other plant materials from which resveratrol is extracted should be carefully selected and monitored. If the quality of the raw materials varies, it can lead to differences in the concentration and purity of the resveratrol extract.

- Manufacturing processes also need to be standardized. This includes factors such as extraction methods, purification procedures, and packaging. Any deviation in these processes can affect the final product's quality. For instance, using different extraction solvents or extraction times can result in varying levels of resveratrol and other active compounds in the extract.

3.2. Accurate Labeling

- Accurate labeling is a key aspect of reliability. Manufacturers must clearly state the content of resveratrol in their products. This helps consumers make informed decisions. If the label indicates a certain amount of resveratrol but the actual content is different, it can mislead consumers and may even have legal implications.

- Labels should also include other relevant information such as the source of resveratrol, any additional ingredients, and proper usage instructions. For example, if the resveratrol extract is combined with other herbs or nutrients, the label should clearly list them along with their respective amounts.

3.3. Trustworthy Production

- Manufacturers need to adhere to good manufacturing practices (GMP). This involves maintaining a clean and hygienic production environment, proper equipment maintenance, and trained staff. A GMP - compliant facility reduces the risk of contamination, which is crucial for a product that is intended for human consumption.

- Quality control and quality assurance procedures should be in place at every stage of production. This includes testing the raw materials, in - process samples, and the final product. For example, spectroscopic techniques can be used to accurately measure the concentration of resveratrol in the extract.

4. Efficiency in Resveratrol Extract Manufacturing

4.1. Streamlined Manufacturing

- A streamlined manufacturing process is essential for efficiency. This means minimizing unnecessary steps and optimizing the workflow. For example, using automated extraction equipment can reduce human error and increase the speed of production. Automated systems can also ensure more precise control over extraction parameters such as temperature, pressure, and extraction time.

- Inventory management is also part of streamlined manufacturing. Manufacturers should maintain an appropriate level of raw materials and finished products in stock. Overstocking can lead to increased storage costs, while understocking can result in production delays.

4.2. Optimized Extraction

- Optimizing the extraction process is crucial for obtaining high - quality resveratrol extract. Different extraction methods such as solvent extraction, supercritical fluid extraction, and microwave - assisted extraction have their own advantages and disadvantages. Manufacturers need to choose the most suitable method based on factors such as cost, efficiency, and product quality. For example, supercritical fluid extraction can produce a cleaner extract with a higher concentration of resveratrol, but it may be more expensive than solvent extraction.

- The extraction conditions, such as the type and concentration of the solvent, temperature, and pressure, also need to be optimized. These factors can affect the yield and purity of the resveratrol extract. By carefully adjusting these conditions, manufacturers can maximize the extraction of resveratrol while minimizing the extraction of unwanted compounds.

4.3. Timely Delivery

- Timely delivery is important for both manufacturers and consumers. For manufacturers, it helps to maintain good relationships with distributors and retailers. For consumers, it ensures that they can start using the product as expected. Delays in delivery can lead to dissatisfaction among customers and may even cause them to look for alternative products.

- To ensure timely delivery, manufacturers need to have efficient logistics and supply chain management. This includes proper planning of production schedules, transportation arrangements, and inventory control. For example, having a reliable shipping partner and accurate forecasting of demand can help to avoid delivery delays.

5. Meeting Consumer Expectations

5.1. Quality Expectations

Consumers expect high - quality resveratrol - based products. This means that the product should be pure, free from contaminants, and have a consistent level of resveratrol. Manufacturers need to meet these quality expectations by focusing on reliability aspects such as consistent quality control and accurate labeling. For example, consumers may be disappointed if they purchase a resveratrol supplement that contains impurities or has a much lower resveratrol content than advertised.5.2. Efficacy Expectations

In addition to quality, consumers also expect the product to be effective. Since resveratrol is associated with various health benefits, consumers hope that the product they use will deliver these benefits. Manufacturers can meet these efficacy expectations through efficient manufacturing processes. For instance, an optimized extraction process can ensure that the resveratrol extract contains a sufficient amount of the active compound to potentially produce the desired health effects.6. Conclusion

In conclusion, resveratrol is a valuable compound with great potential in the health - related product market. Top resveratrol extract manufacturers must uphold reliability and efficiency as the two pillars in their production processes. By ensuring consistent quality, accurate labeling, and trustworthy production (reliability), and by streamlining manufacturing, optimizing extraction, and ensuring timely delivery (efficiency), manufacturers can create resveratrol - based products that meet the high expectations of consumers regarding quality and efficacy. This will not only benefit the consumers but also contribute to the long - term success of the manufacturers in the competitive market of resveratrol - based products.

FAQ:

What does reliability mean for resveratrol extract manufacturers?

Reliability for resveratrol extract manufacturers means consistent quality. This ensures that each batch of the extract has the same level of purity and potency. It also involves accurate labeling, where the information on the product label such as the amount of resveratrol, ingredients, and usage instructions are correct. Trustworthy production processes are part of reliability as well, which includes using safe and clean production facilities and following strict quality control standards.

How is efficiency achieved in the manufacturing of resveratrol extract?

Efficiency in resveratrol extract manufacturing is achieved through streamlined manufacturing processes. This may involve using advanced machinery and technology to reduce production time and waste. Optimized extraction methods are also crucial, such as choosing the most effective solvents and extraction techniques to get the maximum amount of resveratrol from the raw materials. Timely delivery is another aspect of efficiency, ensuring that the products reach the market or the customers on time without unnecessary delays.

Why are reliability and efficiency important for top resveratrol extract manufacturers?

Reliability and efficiency are important for top resveratrol extract manufacturers because they are the pillars for providing effective products. Consumers have high expectations regarding the quality and efficacy of resveratrol - based products. Reliability ensures that the products meet these quality expectations, while efficiency allows the manufacturers to produce and deliver these products in a cost - effective and timely manner, which is essential for staying competitive in the market.

What are the consequences if a resveratrol extract manufacturer lacks reliability?

If a resveratrol extract manufacturer lacks reliability, there can be several consequences. Firstly, the quality of the product may vary, which can lead to inconsistent results for consumers. Inaccurate labeling can mislead consumers about the product's contents or usage, potentially causing harm or dissatisfaction. Additionally, a lack of trust in the production process may lead to a loss of customers and a damaged reputation in the market.

How can consumers identify reliable and efficient resveratrol extract manufacturers?

Consumers can identify reliable and efficient resveratrol extract manufacturers in several ways. They can look for manufacturers with a good reputation in the industry, which can be determined by reading reviews and testimonials from other customers or industry experts. Certifications such as Good Manufacturing Practice (GMP) can also indicate that a manufacturer follows strict quality and production standards. Additionally, transparency in the manufacturing process, such as providing detailed information about the sourcing of raw materials and the extraction methods, can be a sign of a reliable and efficient manufacturer.

Related literature

- The Role of Resveratrol in Health and Disease: A Review"

- "Resveratrol: A Potent Compound from Plants and its Industrial Production"

- "Quality Control in Resveratrol Extract Manufacturing"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Withania Somnifera Extract

2024-12-18

-

Pueraria Lobata Extract

2024-12-18

-

Grape Leaf Extract

2024-12-18

-

Saffron Extract Powder

2024-12-18

-

Kelp Extract Powder

2024-12-18

-

White mustard seed extract

2024-12-18

-

Nettle leaf extract

2024-12-18

-

Dandelion Root Extract

2024-12-18

-

Berberis aristata Extract

2024-12-18

-

Curcuma Longa Extract

2024-12-18