- 0086-571-85302990

- sales@greenskybio.com

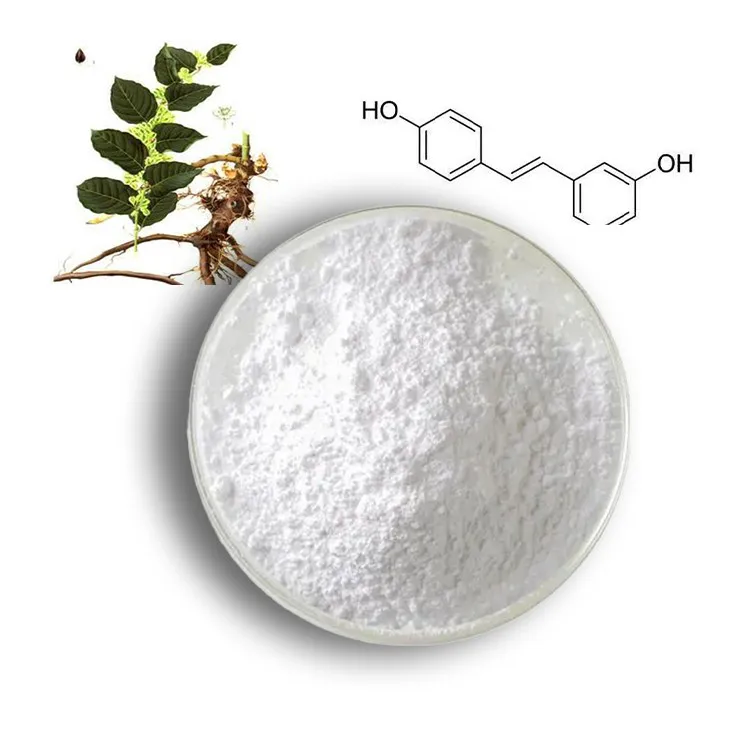

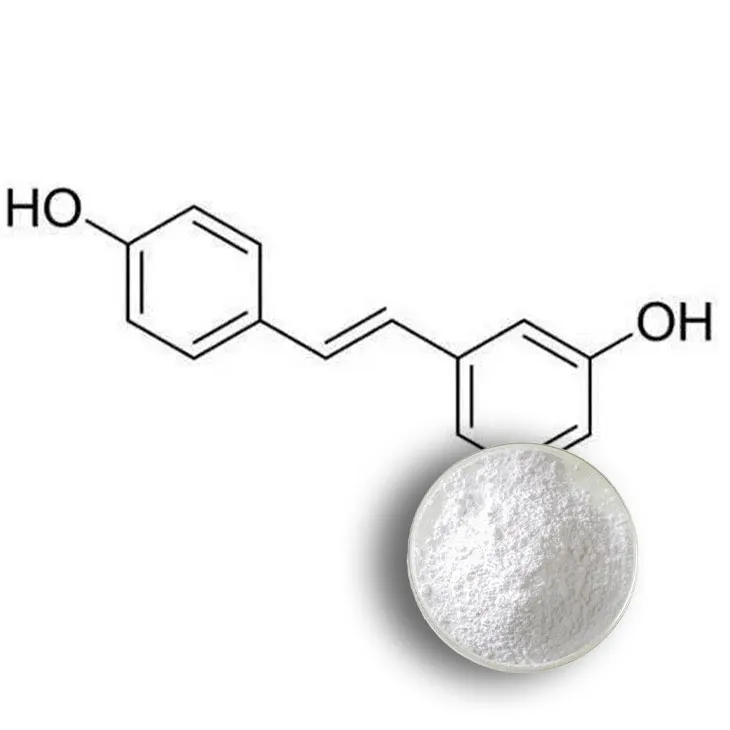

Resveratrol extract products: Which extraction technologies should your enterprise invest in?

2024-12-18

1. Introduction

Resveratrol is a compound that has attracted significant attention in recent years due to its potential health benefits. It is found in various sources such as grapes, berries, and peanuts. As the demand for resveratrol - based products continues to grow, enterprises are faced with the decision of choosing the most appropriate extraction technology. This article aims to provide an in - depth analysis of different extraction technologies relevant to resveratrol products to assist enterprises in making informed investment decisions.

2. Maceration

Maceration is one of the simplest and most widely - used extraction methods for resveratrol.

2.1 Principle

The principle behind maceration is the soaking of the plant material (source of resveratrol) in a solvent. The solvent penetrates the plant cells, dissolving the resveratrol and other soluble compounds. Commonly used solvents include ethanol, methanol, and water. Over time, the resveratrol diffuses into the solvent, creating a solution rich in the desired compound.

2.2 Advantages

- Simplicity: Maceration does not require complex equipment. A simple container for soaking the plant material in the solvent is often sufficient. This makes it an accessible method for small - scale enterprises or those with limited resources.

- Low cost: The equipment and materials required for maceration are relatively inexpensive. Solvents such as ethanol are readily available, and the cost of setting up a basic maceration setup is minimal compared to more advanced extraction technologies.

2.3 Disadvantages

- Long extraction time: Maceration can be a time - consuming process. It may take several days to weeks to achieve a satisfactory extraction rate, depending on the nature of the plant material and the solvent used. This long extraction time can limit production capacity.

- Lower extraction efficiency: Compared to some of the more advanced extraction methods, maceration may not extract all of the available resveratrol from the plant material. Some of the resveratrol may remain trapped within the plant cells, resulting in a lower overall yield.

3. Ultrasonic - Assisted Extraction

Ultrasonic - assisted extraction is an emerging technology that has shown great promise in Resveratrol extraction.

3.1 Principle

Ultrasonic waves are applied to the extraction system. These waves create cavitation bubbles in the solvent. When these bubbles collapse, they generate intense local energy and shockwaves. These shockwaves disrupt the plant cell walls, facilitating the release of resveratrol into the solvent. The ultrasonic energy also enhances the mass transfer of resveratrol from the plant material to the solvent, increasing the extraction rate.

3.2 Advantages

- Enhanced extraction rate: The use of ultrasonic waves significantly reduces the extraction time. In some cases, extraction times can be reduced from days (in maceration) to hours. This allows for higher production volumes in a shorter period.

- Improved extraction efficiency: The disruption of plant cell walls by ultrasonic cavitation ensures that more resveratrol is released from the plant material. This results in a higher yield compared to traditional maceration methods.

3.3 Disadvantages

- Equipment cost: Ultrasonic - assisted extraction requires specialized ultrasonic equipment. These devices can be relatively expensive, especially for high - power and large - scale applications. This initial investment can be a significant barrier for some enterprises.

- Complex operation: Operating ultrasonic - assisted extraction equipment requires a certain level of technical knowledge. There are parameters such as ultrasonic frequency, power, and treatment time that need to be optimized for each specific plant material and solvent system. Incorrect parameter settings can lead to sub - optimal extraction results.

4. Enzymatic Extraction

Enzymatic extraction is another innovative approach to Resveratrol extraction.

4.1 Principle

Enzymes are added to the plant material - solvent system. These enzymes break down the cell walls of the plant material in a more targeted and gentle way compared to mechanical or chemical methods. For example, cellulase enzymes can break down the cellulose in the plant cell walls, allowing easier access to the resveratrol inside the cells. The enzymes catalyze specific reactions that degrade the cell wall components, facilitating the release of resveratrol into the solvent.

4.2 Advantages

- High - quality extracts: Enzymatic extraction can produce Resveratrol extracts with high purity and quality. Since the enzymes act specifically on the cell walls, there is less damage to the resveratrol molecule itself. This can result in extracts with better biological activity and fewer impurities.

- Environmentally friendly: Enzymes are generally biodegradable and less harmful to the environment compared to some of the harsh solvents used in other extraction methods. This makes enzymatic extraction a more sustainable option for enterprises concerned with environmental impact.

4.3 Disadvantages

- Enzyme cost: High - quality enzymes can be expensive. The cost of purchasing and maintaining a sufficient supply of enzymes for large - scale resveratrol extraction can be a significant expense for an enterprise.

- Longer reaction time: Although enzymatic extraction is more targeted, it often requires a longer reaction time compared to ultrasonic - assisted extraction. This is because the enzymatic reactions occur at a specific rate, and rushing the process may lead to incomplete cell wall degradation and lower resveratrol yields.

5. Comparison and Considerations for Enterprises

When considering which extraction technology to invest in, enterprises need to take into account several factors.

5.1 Production Scale

For small - scale production, maceration may be a viable option due to its simplicity and low cost. However, as production scale increases, the limitations of maceration in terms of extraction time and efficiency become more apparent. Ultrasonic - assisted extraction and enzymatic extraction may be more suitable for medium - to large - scale production, but they require higher initial investments.

5.2 Cost - Benefit Analysis

Enterprises need to conduct a detailed cost - benefit analysis. This includes not only the initial investment in equipment and materials but also the ongoing costs such as solvent or enzyme replacement, energy consumption, and labor. For example, while ultrasonic - assisted extraction has a high initial equipment cost, its shorter extraction time may lead to lower overall labor and energy costs in the long run. Enzymatic extraction, on the other hand, has a high enzyme cost but may produce higher - value extracts.

5.3 Product Quality Requirements

If the enterprise is targeting high - end markets with strict product quality requirements, enzymatic extraction may be the preferred choice due to its ability to produce high - quality extracts. However, if cost is a more significant factor and a certain level of impurity can be tolerated, maceration or ultrasonic - assisted extraction may be sufficient.

6. Conclusion

In conclusion, each extraction technology - maceration, ultrasonic - assisted extraction, and enzymatic extraction - has its own advantages and disadvantages. Enterprises need to carefully evaluate their production scale, cost - benefit analysis, and product quality requirements when deciding which extraction technology to invest in. By making an informed decision, enterprises can ensure the efficient and cost - effective production of resveratrol extract products, meeting the demands of the market and achieving long - term success.

FAQ:

What is maceration in resveratrol extraction?

Maceration is a simple and commonly - used extraction method for resveratrol. It involves soaking the plant material containing resveratrol in a solvent for a certain period. During this time, the resveratrol is gradually dissolved into the solvent, allowing for its extraction. This method is relatively straightforward but may have a longer extraction time compared to some other techniques.

How does ultrasonic - assisted extraction improve resveratrol extraction?

Ultrasonic - assisted extraction enhances the resveratrol extraction rate. The ultrasonic waves create cavitation bubbles in the solvent. When these bubbles collapse, they generate intense local forces and high - temperature and - pressure micro - environments. These effects can break the cell walls of the plant material more effectively, facilitating the release of resveratrol into the solvent, thus increasing the extraction efficiency.

What are the advantages of enzymatic extraction for resveratrol?

Enzymatic extraction has the potential to obtain high - quality resveratrol extracts. Enzymes can specifically target the cell wall components of the plant material. By hydrolyzing these components, they can make the resveratrol more accessible for extraction. This method may also be more environmentally friendly and can produce extracts with better purity and quality compared to some traditional extraction methods.

How do enterprises decide which resveratrol extraction technology to invest in?

Enterprises need to consider several factors when choosing an extraction technology for resveratrol. They should look at the cost of equipment and operation for each method. The extraction efficiency and yield are also crucial, as a higher yield means more product can be obtained. The quality of the extract, including its purity and potential for further processing, is another consideration. Additionally, environmental factors and regulatory compliance may play a role in the decision - making process.

Are there any drawbacks to the different resveratrol extraction technologies?

Yes, each extraction technology has its drawbacks. For maceration, as mentioned before, it may be time - consuming. Ultrasonic - assisted extraction may require special equipment and skilled operators, and the equipment may be relatively expensive. Enzymatic extraction may need careful control of enzyme activity and reaction conditions, and the cost of enzymes can also be a factor. Additionally, some extraction methods may produce by - products that need to be further processed or removed.

Related literature

- Advances in Resveratrol Extraction: A Review of Modern Techniques"

- "Resveratrol: Extraction Technologies and Their Impact on Product Quality"

- "Comparative Study of Different Resveratrol Extraction Methods for Industrial Applications"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Calendula Extract

2024-12-18

-

Oat Straw Extract Powder

2024-12-18

-

Lemon Extract

2024-12-18

-

Phyllanthus Emblica Extract

2024-12-18

-

Passionflower Extract

2024-12-18

-

Beetroot Powder

2024-12-18

-

Acerola Juice Powder

2024-12-18

-

Curcuma Longa Extract/Turmeric extract

2024-12-18

-

Quercetin

2024-12-18

-

Mango flavored powder

2024-12-18