- 0086-571-85302990

- sales@greenskybio.com

Understand the main processes of garcinia cambogia extract manufacturing in the food industry.

2024-12-20

1. Introduction

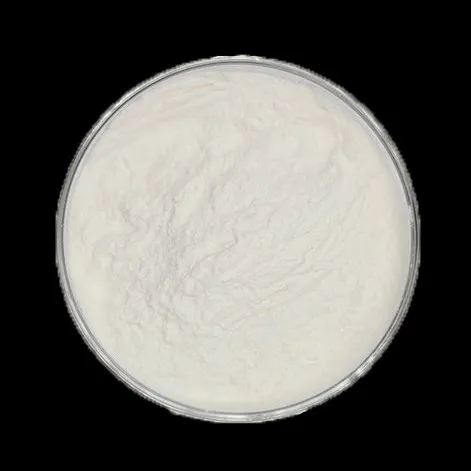

Garcinia cambogia has gained significant popularity in the food industry, especially in the realm of weight - loss products and functional foods. The extract of Garcinia cambogia contains active substances that are believed to have various beneficial effects. Understanding the manufacturing process of this extract is crucial for ensuring its quality and safety in food applications.

2. Plant Selection

The manufacturing process of Garcinia Cambogia Extract begins with the selection of plants. This is a critical step as the quality and variety of the Garcinia cambogia plants directly impact the quality of the final extract.

- Suitable Varieties: Different varieties of Garcinia cambogia may have varying levels of active substances. Manufacturers need to select the varieties that are known to have a high content of the desired compounds, such as hydroxycitric acid (HCA), which is often associated with the potential weight - loss effects of the extract.

- Quality Considerations: The plants should be healthy, free from diseases and pests. Plants grown in optimal environmental conditions, such as proper soil, sunlight, and water, are more likely to produce high - quality fruits from which the extract can be obtained.

3. Harvesting and Immediate Processing

Once the Garcinia cambogia fruits are ripe, they are harvested. Immediate processing is necessary to preserve the active substances in the fruits.

- Harvesting Time: The right time for harvesting is crucial. Harvesting too early or too late can affect the quality of the fruits and, consequently, the extract. Fruits should be harvested when they have reached the optimal stage of ripeness, which is typically determined by factors such as color, firmness, and chemical composition.

- Transport and Storage: After harvesting, the fruits need to be carefully transported to the processing facility. They should be stored under appropriate conditions, such as cool temperatures and low humidity, to prevent spoilage and degradation of the active substances.

4. Maceration

Maceration is one of the initial processing steps in the production of Garcinia Cambogia Extract. During this process, the fruits are soaked in a liquid medium.

- Purpose of Maceration: The main objective of maceration is to break down the cell walls of the fruit tissues. This helps in releasing the active substances, such as HCA, which are trapped inside the cells. By soaking the fruits in a suitable liquid, the cell walls become more permeable, allowing the active substances to diffuse out into the liquid medium.

- Choice of Liquid Medium: The liquid medium used for maceration can vary. Commonly, solvents such as water or ethanol are used. The choice depends on factors such as the solubility of the active substances, the desired extraction efficiency, and the safety and regulatory requirements for food - grade extracts. For example, water is a natural and safe solvent, but ethanol may be more effective in extracting certain hydrophobic compounds.

- Maceration Conditions: The maceration process is typically carried out under controlled conditions. Parameters such as temperature, time, and the ratio of fruit to liquid medium need to be optimized. Higher temperatures may increase the rate of cell wall breakdown, but excessive heat can also degrade the active substances. Similarly, longer maceration times may lead to higher extraction yields, but may also increase the risk of contamination or unwanted chemical reactions.

5. Extraction Methods: Distillation and Pressing

After maceration, the next step is to obtain the extract from the macerated mixture. Two common methods used are distillation and pressing.

- Distillation:

- Principle: Distillation is based on the difference in boiling points of the components in the macerated mixture. The liquid mixture is heated, and the volatile components, including the active substances and the solvent (if applicable), are vaporized. The vapors are then condensed back into a liquid, which is collected as the extract.

- Types of Distillation: There are different types of distillation methods, such as simple distillation and fractional distillation. Simple distillation is suitable for mixtures with a large difference in boiling points between the active substances and other components. Fractional distillation is more complex and can be used to separate components with closer boiling points, allowing for a more refined extract.

- Advantages and Disadvantages: One advantage of distillation is that it can produce a relatively pure extract. However, it can be energy - intensive and may require specialized equipment. Additionally, some heat - sensitive active substances may be degraded during the distillation process.

- Pressing:

- Principle: Pressing involves applying mechanical force to the macerated fruits to squeeze out the liquid extract. This method is more straightforward compared to distillation and does not require heating.

- Equipment and Process: Pressing can be done using various types of presses, such as hydraulic presses or screw presses. The macerated fruits are placed in a press, and the force is gradually applied to extract the liquid. The resulting extract may contain some solid particles, which may need further separation.

- Advantages and Disadvantages: Pressing is a relatively simple and energy - efficient method. However, the extract obtained may not be as pure as that from distillation, and it may require additional filtration or purification steps to remove solid impurities.

6. Refinement: Centrifugation and Chemical Purification

The extract obtained from distillation or pressing may contain a significant amount of impurities. Therefore, further refinement is essential to improve the quality of the extract.

- Centrifugation:

- Principle: Centrifugation is a physical separation method based on the difference in density between the solid and liquid components in the extract. The extract is placed in a centrifuge, and when the centrifuge rotates at high speed, the denser solid particles are forced to the bottom of the container, while the liquid supernatant can be easily separated.

- Effectiveness: Centrifugation is an effective method for quickly separating large - sized solid impurities from the liquid extract. It can significantly improve the clarity of the extract and reduce the amount of particulate matter.

- Limitations: However, centrifugation may not be sufficient to remove all types of impurities, especially those that are very fine or dissolved in the liquid phase.

- Chemical Purification:

- Principle: Chemical purification methods involve the use of chemical reactions to remove unwanted substances from the extract. For example, acids or bases may be used to adjust the pH of the extract, which can cause certain impurities to precipitate out. Chelating agents can be used to bind and remove heavy metals, which may be present as contaminants.

- Safety and Regulatory Considerations: When using chemical purification methods, it is crucial to ensure that the chemicals used are food - grade and safe for consumption. Additionally, strict regulatory compliance is required to ensure that the final extract meets all safety and quality standards.

- Complexity: Chemical purification can be a more complex process compared to centrifugation, as it requires careful control of reaction conditions, such as the concentration of chemicals, reaction time, and temperature. Incorrect conditions can lead to the loss of active substances or the introduction of new impurities.

7. Dehydration and Stabilization

Once the extract has been purified, the next step is dehydration and stabilization to make it suitable for use as an ingredient in food products.

- Dehydration:

- Methods: There are several methods for dehydrating the Garcinia Cambogia Extract. One common method is evaporation, where the liquid extract is heated under controlled conditions to remove the water or solvent. Another method is freeze - drying, which involves freezing the extract and then removing the ice crystals by sublimation under low pressure. Freeze - drying is often preferred for heat - sensitive extracts as it can preserve the activity of the active substances better.

- Importance: Dehydration is necessary to reduce the moisture content of the extract, which helps in preventing spoilage and microbial growth. It also makes the extract more stable during storage and transportation.

- Stabilization:

- Additives: To further stabilize the extract, various additives may be used. For example, antioxidants can be added to prevent oxidation of the active substances. Emulsifiers may be used if the extract is to be incorporated into emulsion - based food products, such as salad dressings or spreads. Stabilizers can also be added to improve the shelf - life and physical stability of the extract in different food matrices.

- Packaging: The packaging of the stabilized extract is also an important aspect of stabilization. The extract should be packaged in air - tight containers to prevent exposure to air, moisture, and light, which can degrade the active substances. Packaging materials such as aluminum foil or laminated plastics are often used to provide a good barrier against environmental factors.

8. Incorporation into Food Products

After the Garcinia cambogia extract has been processed and stabilized, it can be incorporated into different food products.

- Weight - Loss Products: Garcinia cambogia extract is commonly used in weight - loss supplements, such as capsules or tablets. It may also be added to functional foods like meal replacement bars or drinks, where its potential weight - loss effects are promoted.

- Functional Foods: In addition to weight - loss products, the extract can be used in other functional foods. For example, it may be added to yogurt or other dairy products for its potential health - promoting properties. It can also be incorporated into baked goods, such as muffins or cookies, as a functional ingredient.

- Formulation Considerations: When incorporating the extract into food products, several factors need to be considered. These include the compatibility of the extract with other ingredients in the product, the desired dosage of the extract, and the impact of the extract on the sensory properties (such as taste, texture, and color) of the food product.

9. Conclusion

The manufacturing process of Garcinia cambogia extract in the food industry is a complex and multi - step process. From plant selection to incorporation into food products, each step plays a crucial role in ensuring the quality, safety, and effectiveness of the extract. Understanding these processes is essential for manufacturers, regulatory agencies, and consumers alike, as it helps in ensuring that Garcinia cambogia - based products meet the highest standards of quality and safety in the food market.

FAQ:

1. What is the first step in Garcinia cambogia extract manufacturing?

The first step is the selection of Garcinia cambogia plants. The right variety and quality of the plants are crucial as they directly affect the quality of the extract.

2. Why is maceration carried out during the manufacturing process?

Maceration is carried out to soak the fruits in a liquid medium. This helps break down the cell walls and release the active substances.

3. How is the extract obtained after maceration?

After maceration, the extract is obtained through distillation or pressing.

4. Why is further refinement necessary after the initial extraction?

Because the extract at the initial stage may contain a lot of impurities, so further refinement is necessary to make it suitable for use in food products.

5. What methods are used for further refinement?

Centrifugation can be used to separate the solid and liquid parts more effectively, and chemical purification methods are also often used to eliminate harmful or unwanted substances.

6. How is the purified extract made into a form suitable for food products?

The purified extract is dehydrated and made into a stable form, which can be easily incorporated into different food products as an ingredient.

Related literature

- Garcinia cambogia: A comprehensive review of its phytochemistry, pharmacology, and safety"

- "The production and applications of Garcinia cambogia extract in the food and pharmaceutical industries"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Gynostemma pentaphyllum extract

2024-12-20

-

Artichoke Extract

2024-12-20

-

Berberis aristata Extract

2024-12-20

-

Bayberry Extract

2024-12-20

-

Black Rice Extract

2024-12-20

-

Camu Camu Extract

2024-12-20

-

Selenium yeast

2024-12-20

-

Citrus bioflavonoids

2024-12-20

-

Bitter Melon Extract

2024-12-20

-

Nettle Root Extract

2024-12-20