- 0086-571-85302990

- sales@greenskybio.com

Diosmin Manufacturers from China.

2024-11-27

1. Introduction to Chinese Diosmin Manufacturers

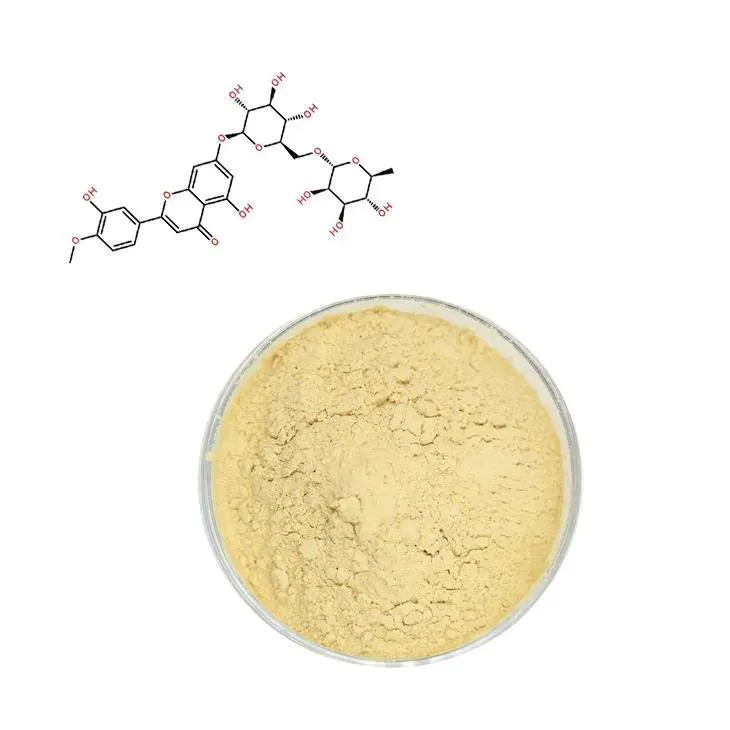

In the global Diosmin manufacturing landscape, Chinese manufacturers have emerged as significant contributors. Diosmin, a flavonoid with various beneficial properties, has seen a rise in demand in the pharmaceutical, nutraceutical, and cosmetic industries. Chinese manufacturers are leveraging their resources and expertise to meet this growing demand.

2. Comprehensive Manufacturing Processes

2.1 Raw Material Sourcing

Chinese Diosmin manufacturers are meticulous in the initial stage of raw material sourcing. They ensure that the raw materials used are of high quality. This involves working with reliable suppliers, often local farmers or agricultural cooperatives, to obtain the plant materials from which Diosmin is extracted. For example, citrus fruits are a common source of Diosmin. Manufacturers conduct strict quality checks on these raw materials, including tests for purity, freshness, and absence of contaminants.

2.2 Production Steps

The production process of Diosmin in China is a complex yet well - organized sequence of steps. After sourcing the raw materials, the extraction process begins. Advanced extraction techniques are employed to isolate Diosmin from the plant matrices. These techniques include solvent extraction and supercritical fluid extraction, which are chosen based on their efficiency and ability to preserve the integrity of Diosmin.- During solvent extraction, appropriate solvents are carefully selected to dissolve Diosmin from the plant material. This step requires precise control of temperature, pressure, and extraction time to ensure maximum yield and purity.

- Supercritical fluid extraction, on the other hand, uses substances in a supercritical state (e.g., carbon dioxide) to extract Diosmin. This method is considered more environmentally friendly as it reduces the use of harmful solvents.

2.3 Packaging

The final step in the manufacturing process is packaging. Chinese manufacturers pay great attention to packaging as it plays a vital role in protecting the Diosmin product during storage and transportation. Packaging materials are selected based on their ability to prevent moisture, light, and air from degrading the Diosmin. For example, opaque, air - tight containers are commonly used. Additionally, proper labeling is done to provide essential information such as product specifications, batch numbers, and expiry dates.3. Environmental and Safety Regulations

Chinese Diosmin manufacturers are highly committed to following strict environmental and safety regulations.

- Environmental Protection: In terms of environmental protection, they strive to minimize the environmental impact of their production processes. For instance, during the extraction process, waste management is a key aspect. Manufacturers take measures to properly dispose of waste solvents and by - products in an environmentally friendly manner. They also invest in technologies that reduce energy consumption and emissions. For example, some factories have installed energy - efficient extraction equipment that not only reduces electricity usage but also lowers greenhouse gas emissions.

- Safety Standards: When it comes to safety standards, the manufacturers ensure the safety of their workers and the end - users of their products. Workers are provided with proper safety training and protective equipment. In the production facilities, safety protocols are strictly adhered to, such as proper handling of chemicals and maintenance of safe working conditions. For the end - users, product safety is guaranteed through rigorous quality control and compliance with international safety standards. This includes testing for any potential allergens or harmful substances in the Diosmin products.

4. Research and Development Efforts

4.1 Optimization of Production Yield

The R & D teams of Chinese Diosmin manufacturers are constantly focused on optimizing the production yield of Diosmin. They conduct in - depth research on the extraction and purification processes to find ways to increase the amount of Diosmin obtained from a given amount of raw material. This involves experimenting with different extraction parameters, such as changing the solvent - to - raw - material ratio or adjusting the extraction time. Through these efforts, manufacturers can improve their production efficiency and reduce costs, which in turn makes their Diosmin products more competitive in the global market.

4.2 Enhancement of Purity

Another important aspect of R & D is the enhancement of the purity of Diosmin. High - purity Diosmin is highly desirable for its enhanced effectiveness in various applications. R & D teams are exploring new purification techniques and improving existing ones. For example, they are researching on advanced chromatography methods that can separate Diosmin from closely related compounds more effectively. By increasing the purity of Diosmin, manufacturers can target high - end markets where quality requirements are extremely stringent.5. Collaboration with International Research Institutions

Chinese Diosmin manufacturers recognize the importance of collaborating with international research institutions.

- Knowledge Exchange: These collaborations facilitate knowledge exchange. International research institutions often have the latest scientific research findings and advanced technological know - how. By partnering with them, Chinese manufacturers can gain access to this valuable knowledge. For example, they can learn about new extraction methods or purification techniques that are being developed overseas.

- Market Trends Awareness: Collaboration also helps Chinese manufacturers stay updated with the latest market trends. International research institutions conduct market research and analysis, which can provide valuable insights into the changing demands for Diosmin in different regions of the world. This information allows manufacturers to adjust their production strategies accordingly, such as focusing on developing new Diosmin - based products that are in high demand in international markets.

- Quality and Competitiveness Improvement: Overall, the collaboration with international research institutions enhances the quality and competitiveness of Chinese Diosmin products in the global market. Manufacturers can incorporate the latest scientific advancements into their production processes, resulting in higher - quality products. They can also use the market intelligence gained from the collaborations to better position their products in the international marketplace, competing effectively with products from other countries.

6. Conclusion

Chinese Diosmin manufacturers play a crucial role in the global Diosmin market. Their comprehensive manufacturing capabilities, strict adherence to environmental and safety regulations, continuous R & D efforts, and collaborations with international research institutions all contribute to their success. As the demand for Diosmin continues to grow in various industries, Chinese manufacturers are well - positioned to meet this demand and further enhance their presence in the global market.

FAQ:

What are the advantages of Chinese Diosmin manufacturers?

Chinese Diosmin manufacturers have several advantages. They possess comprehensive manufacturing capabilities, carefully monitor every step from raw material sourcing to final packaging. They adhere to strict environmental and safety regulations for sustainable production. Their R & D teams are dedicated to optimizing production yield and purity, and they collaborate with international research institutions to keep up with the latest findings and trends, enhancing product quality and competitiveness.

How do Chinese Diosmin manufacturers ensure product quality?

They ensure product quality in multiple ways. Firstly, they strictly monitor all production steps including raw material sourcing and packaging. Secondly, they follow environmental and safety regulations. Their R & D teams work on optimizing production yield and purity. Also, the collaboration with international research institutions helps them to stay informed about the latest scientific knowledge related to Diosmin, which in turn benefits the quality of their products.

What role does R & D play in Chinese Diosmin manufacturing?

The R & D in Chinese Diosmin manufacturing plays a crucial role. It focuses on optimizing the production yield and purity of Diosmin. By constantly researching and developing new techniques and methods, they can improve the overall quality of the Diosmin products. This also helps the manufacturers to be more competitive in the global market.

How do Chinese Diosmin manufacturers keep up with market trends?

Chinese Diosmin manufacturers keep up with market trends by collaborating with international research institutions. Through this collaboration, they can access the latest scientific findings which are often related to market trends. This enables them to adjust their production and product features accordingly, ensuring their Diosmin products remain competitive in the global market.

Why is the collaboration with international research institutions important for Chinese Diosmin manufacturers?

The collaboration with international research institutions is important for Chinese Diosmin manufacturers. It allows them to stay updated with the latest scientific findings. This helps in optimizing the production of Diosmin in terms of yield and purity. Moreover, it enables them to keep track of market trends, which is crucial for enhancing the quality and competitiveness of their Diosmin products in the global market.

Related literature

- Diosmin Production: Innovations from Chinese Manufacturers"

- "The Role of Chinese Diosmin Manufacturers in the Global Market"

- "Sustainable Diosmin Manufacturing in China: A Review"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

The best lemon juice powder in nature.

2024-11-27

-

Organic Vitamin K2 Powder Suppliers

2024-11-27

-

Bulk purchase of L - tyrosine.

2024-11-27

-

Vitamin K2 Manufacturers

2024-11-27

-

100% Pure Natural Rutin.

2024-11-27

-

Chinese Citrus Bioflavonoid Suppliers.

2024-11-27

-

Pine bark Extract Powder

2024-11-27

-

Rosemary extract

2024-11-27

-

Sophora Japonica Flower Extract

2024-11-27

-

Hops Extract

2024-11-27

-

Withania Somnifera Extract

2024-11-27

-

Green Tea Extract

2024-11-27

-

Scutellaria Extract

2024-11-27

-

Tongkat Ali Extract Powder

2024-11-27

-

Soy Extract

2024-11-27

-

Kidney Bean Extract

2024-11-27