- 0086-571-85302990

- sales@greenskybio.com

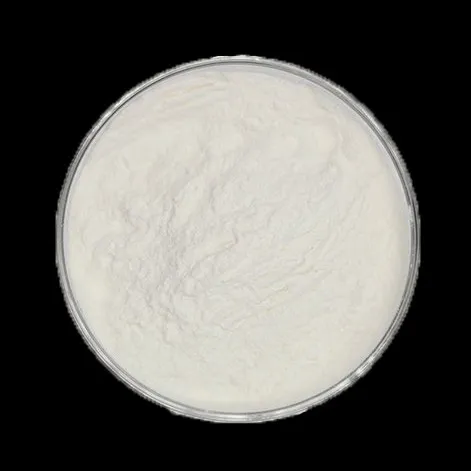

How to make powder from saw palmetto extract?

2024-12-02

1. Introduction

Saw Palmetto Extract has been widely studied for its potential health benefits, and converting it into powder form can increase its usability in various applications such as in dietary supplements. However, the process is not straightforward and requires careful attention to multiple aspects. This article will explore in detail the steps involved in making powder from Saw Palmetto Extract, including harvesting, purification, powder - making techniques, safety measures, and quality testing.

2. Harvesting of Saw Palmetto Berries

2.1 Importance of Harvesting Time

The time at which saw palmetto berries are harvested is critically important. Berries harvested at different stages of maturity can have varying chemical compositions. For example, if the berries are harvested too early, they may not have fully developed the active compounds that are desired in the extract. On the other hand, if they are harvested too late, there could be a degradation of some components or an increase in unwanted substances.- Early - harvested berries might have lower levels of fatty acids and sterols, which are important constituents of Saw Palmetto Extract.

- Late - harvested berries could potentially contain higher amounts of mold or other contaminants due to the longer exposure to environmental factors.

2.2 Harvesting Methods

The method of harvesting also plays a significant role in the quality of the extract. Manual harvesting is often preferred as it allows for more selective picking of ripe berries. However, it is a labor - intensive process.- When using mechanical harvesting, there is a risk of collecting unripe or overripe berries along with the ripe ones. This can lead to a less pure and less effective extract.

- Another aspect to consider is the damage to the plant during harvesting. Rough handling during mechanical harvesting can harm the saw palmetto plants, which may affect future yields and the overall health of the plant population.

3. Purification of the Extract

3.1 Removal of Impurities

Once the extract is obtained from the saw palmetto berries, purification is necessary to remove impurities. These impurities can include plant debris, dirt, and other non - active substances. One common method is filtration.- Coarse Filtration: This is the first step and is used to remove larger particles such as pieces of berry skins and stems. A simple mesh filter can be used for this purpose.

- Fine Filtration: After coarse filtration, fine filtration is carried out to remove smaller particles and some dissolved impurities. Membrane filters or filter papers with a smaller pore size are typically employed.

3.2 Separation of Active Compounds

In addition to removing impurities, sometimes it is necessary to separate and concentrate the active compounds in the saw palmetto extract. Chromatography techniques can be used for this purpose.- Column Chromatography: In column chromatography, the extract is passed through a column filled with a stationary phase. Different compounds in the extract will interact differently with the stationary phase and will be eluted at different times. This allows for the separation of the active compounds from other components.

- High - Performance Liquid Chromatography (HPLC): HPLC is a more advanced and precise chromatography technique. It can be used to accurately separate, identify, and quantify the active compounds in the saw palmetto extract. It is especially useful for quality control purposes.

4. Powder - making Process

4.1 Vacuum Drying

After purification, the extract is usually in a liquid form. To convert it into powder, one of the first steps can be vacuum drying. Vacuum drying has several advantages.- It reduces the drying time as the low - pressure environment allows water to evaporate more quickly compared to normal drying conditions. This helps in preserving the active compounds as they are exposed to less heat for a shorter period.

- The low - oxygen environment in vacuum drying also helps prevent oxidation of the active compounds. Oxidation can lead to a decrease in the effectiveness of the saw palmetto extract.

4.2 Milling

Once the extract has been dried, milling is the next step to convert it into a fine powder. There are different types of mills that can be used depending on the desired particle size and characteristics of the powder.- Ball Mills: Ball mills are commonly used for grinding the dried extract into powder. They consist of a rotating chamber filled with balls. As the chamber rotates, the balls collide with the extract, breaking it into smaller particles. The size of the balls and the rotation speed can be adjusted to control the fineness of the powder.

- Hammer Mills: Hammer mills use a set of hammers to impact the dried extract and break it into powder. They are generally faster than ball mills but may produce a powder with a wider particle size distribution.

- Jet Mills: Jet mills use high - velocity jets of gas to grind the material. They are suitable for producing very fine powders with a narrow particle size distribution. However, they are more expensive and require more complex operating conditions.

5. Safety Measures during Production

5.1 Worker Safety

During the production process of saw palmetto extract powder, ensuring worker safety is of utmost importance. Workers should be provided with appropriate personal protective equipment (PPE).- When handling the raw saw palmetto berries, gloves should be worn to protect against potential skin irritants or allergens present on the berries.

- During the purification and powder - making processes, which may involve the use of chemicals and machinery, safety goggles, and masks should be worn to protect the eyes and respiratory system respectively.

- Proper training should be provided to workers on the safe operation of equipment to prevent accidents such as those caused by improper handling of mills or vacuum drying chambers.

5.2 Product Safety

Ensuring the safety of the final powder product is also crucial. The production environment should be clean and free from contaminants.- All equipment used in the production process should be regularly cleaned and sanitized to prevent the growth of bacteria or other microorganisms. This is especially important for equipment used in the purification and drying steps.

- Quality control checks should be carried out throughout the production process to ensure that the powder does not contain any harmful substances such as heavy metals or pesticides. These contaminants can enter the production process through the raw materials or from the environment.

6. Quality Testing of the Final Powder Product

6.1 Chemical Composition Analysis

Testing the chemical composition of the final powder product is essential to ensure its quality and effectiveness. One of the main components to analyze is the fatty acid profile.- Gas Chromatography - Mass Spectrometry (GC - MS) can be used to identify and quantify the different fatty acids present in the saw palmetto extract powder. This helps in verifying that the powder contains the expected levels of active fatty acids such as lauric acid, myristic acid, and oleic acid.

- Another aspect of chemical composition analysis is the determination of sterol content. High - Performance Liquid Chromatography (HPLC) can be used to measure the levels of sterols like beta - sitosterol, which is an important component of saw palmetto extract.

6.2 Bioactivity Testing

In addition to chemical composition analysis, bioactivity testing is also necessary to evaluate the effectiveness of the saw palmetto extract powder.- In vitro Tests: In vitro tests can be carried out using cell cultures. For example, the powder can be tested for its anti - inflammatory properties by observing its effect on inflammatory markers in cell cultures. This can provide an indication of how the powder may perform in vivo.

- Animal Studies: Animal studies can also be conducted to further evaluate the bioactivity of the powder. For instance, studies on male rats can be used to investigate the effect of the powder on prostate health, as saw palmetto extract is often associated with prostate - related benefits.

7. Conclusion

Making powder from saw palmetto extract is a multi - step process that requires careful consideration at each stage. From the harvesting of the saw palmetto berries to the final quality testing of the powder product, every step impacts the quality, safety, and effectiveness of the final product. By following proper procedures for harvesting, purification, powder - making, safety measures, and quality testing, it is possible to produce high - quality saw palmetto extract powder that can be used in various applications such as dietary supplements and natural medicine.

FAQ:

Question 1: What is the best time to harvest saw palmetto berries for extract?

The best time to harvest saw palmetto berries can vary depending on factors such as geographical location and climate. Generally, it is recommended to harvest when the berries are fully matured. This is usually indicated by a change in color, typically from green to a dark purple or black. Harvesting at the right time ensures that the berries contain the optimal levels of the active compounds for the extract, which in turn affects the quality of the powder made from the extract.

Question 2: What are the common purification methods for saw palmetto extract?

Common purification methods for saw palmetto extract include filtration and chromatography. Filtration can be used to remove large particles and debris. Chromatography, such as high - performance liquid chromatography (HPLC), is often employed to separate and purify the specific active components in the extract. These purification steps are crucial to eliminate impurities and ensure a high - quality extract for powder production.

Question 3: How does vacuum drying work in the powder - making process?

Vacuum drying works by reducing the pressure in the drying chamber. This lowers the boiling point of the solvent (if any) in the saw palmetto extract. As a result, the water or other solvents can be removed at a lower temperature compared to normal drying methods. This helps to preserve the bioactivity of the extract components as they are less likely to be degraded by high heat. The dried extract can then be more easily milled into a powder.

Question 4: What safety measures should be taken during the production of saw palmetto extract powder?

During the production of saw palmetto extract powder, several safety measures should be taken. Workers should wear appropriate personal protective equipment, such as gloves and goggles, especially when handling chemicals during purification. The production area should be well - ventilated to prevent the accumulation of any potentially harmful vapors. Equipment should be regularly maintained and calibrated to ensure proper operation and avoid accidents. Also, strict quality control procedures should be in place to monitor for any contaminants or impurities that could pose a safety risk.

Question 5: How can the bioactivity of the final saw palmetto extract powder be tested?

The bioactivity of the final saw palmetto extract powder can be tested through in vitro and in vivo assays. In vitro assays can include tests on cell cultures to see the effect of the powder's components on cell functions such as proliferation or apoptosis. In vivo assays may involve animal studies to observe the physiological effects of the powder, such as its impact on prostate health in relevant animal models. Additionally, biomarker analysis can be carried out to determine if the powder is having the expected biological effects.

Related literature

- Saw Palmetto Extract: Production and Quality Control"

- "Advances in Saw Palmetto Powder Manufacturing Techniques"

- "The Bioactivity of Saw Palmetto Extract: Analytical Approaches"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

The best lemon juice powder in nature.

2024-12-02

-

Organic Vitamin K2 Powder Suppliers

2024-12-02

-

Bulk purchase of L - tyrosine.

2024-12-02

-

Vitamin K2 Manufacturers

2024-12-02

-

100% Pure Natural Rutin.

2024-12-02

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-02

-

Cassia Seed Extract

2024-12-02

-

Chasteberry Extract

2024-12-02

-

Ivy Extract

2024-12-02

-

Boswellia Serrata Extract

2024-12-02

-

Camu Camu Extract

2024-12-02

-

Artichoke Leaf Extract

2024-12-02

-

Oyster Mushroom Extract Powder

2024-12-02

-

Chia Seed Powder

2024-12-02

-

Mango flavored powder

2024-12-02

-

Hesperidin

2024-12-02