- 0086-571-85302990

- sales@greenskybio.com

Organic Astaxanthin Powder Factory.

2024-12-02

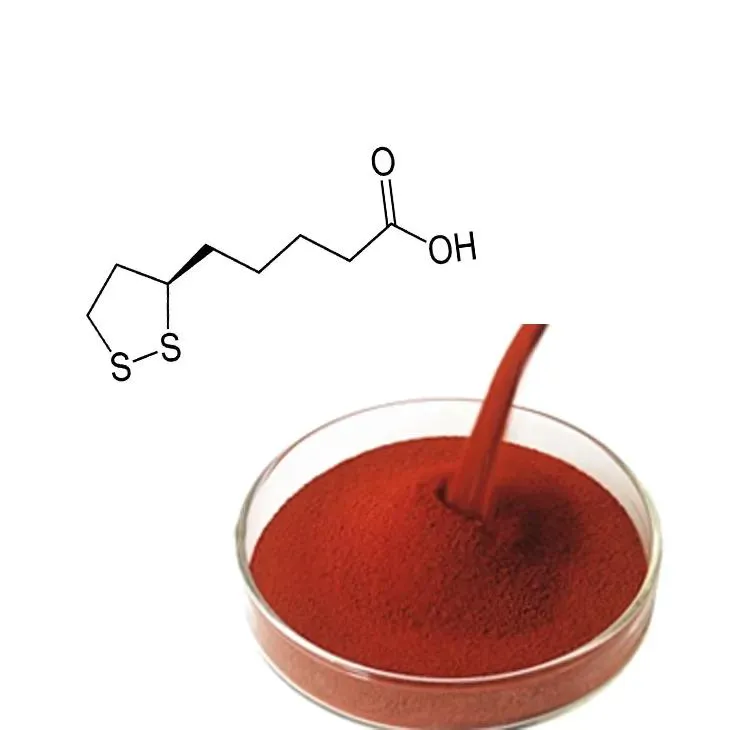

1. Introduction to Organic Astaxanthin Powder

Organic Astaxanthin powder is a remarkable substance that has gained significant attention in recent years. It is highly regarded as a potent antioxidant, which means it has the ability to combat free radicals in the body. Free radicals are unstable molecules that can cause damage to cells, leading to various health problems such as premature aging, heart diseases, and certain types of cancers. The antioxidant properties of Astaxanthin are much stronger compared to other well - known antioxidants like vitamin C and vitamin E. This makes it a valuable ingredient in a wide range of applications, from dietary supplements to cosmetics.

2. The Role of the Factory in the Supply Chain

The organic astaxanthin powder factory plays a crucial role at the heart of the astaxanthin supply chain. It is responsible for converting the raw materials, in this case, microalgae, into a final product that can be distributed and used by various industries. Without the factory, the journey from the cultivation of microalgae to the end - use products containing astaxanthin would not be possible.

3. Sustainable Production Methods

3.1 Strain Selection

The first step in the factory's production process is the selection of suitable microalgae strains for astaxanthin production. This is a critical step as different strains may vary in their astaxanthin - producing capabilities. The factory's researchers and technicians carefully screen and select strains that have high astaxanthin content and are also suitable for large - scale cultivation. These strains are often chosen based on their genetic makeup, growth rate, and adaptability to the cultivation conditions.

3.2 Cultivation Conditions

Once the appropriate strains are selected, they are cultivated in a controlled environment. Maintaining optimal conditions is essential for maximizing astaxanthin production. For example, the temperature needs to be carefully regulated. Different microalgae strains may have different temperature preferences, and the factory must ensure that the temperature is within the suitable range for the selected strain. Similarly, light is another crucial factor. Adequate light intensity and duration are required for photosynthesis, which is vital for the growth and astaxanthin production of microalgae. Additionally, the supply of nutrients such as nitrogen, phosphorus, and potassium must be carefully balanced. Too much or too little of these nutrients can affect the growth and astaxanthin content of the microalgae.

4. The Harvesting and Extraction Process

4.1 Harvesting

When the microalgae have reached the appropriate growth stage, they are harvested. Harvesting is a delicate process as it needs to be done in a way that maximizes the yield of astaxanthin - rich microalgae while minimizing damage to the cells. Different methods can be used for harvesting, such as centrifugation or filtration. Centrifugation uses the principle of centrifugal force to separate the microalgae from the culture medium, while filtration involves passing the culture through a filter to retain the microalgae.

4.2 Extraction

After harvesting, the extraction of astaxanthin is a complex process. It involves state - of - the - art extraction technologies. One common method is solvent extraction, where a suitable solvent is used to dissolve astaxanthin from the microalgae. However, the choice of solvent is crucial as it needs to be effective in extracting astaxanthin while also being safe and compliant with regulatory requirements. Another method is supercritical fluid extraction, which uses a supercritical fluid, such as carbon dioxide, as the extracting agent. This method has the advantage of being more environmentally friendly and can often result in a higher - quality extract.

5. Purification of Astaxanthin

Once the astaxanthin has been extracted, purification steps are carried out to obtain pure organic astaxanthin powder. Purification is necessary to remove any impurities that may be present in the extract, such as other pigments, lipids, or proteins. Different purification techniques can be used, such as chromatography. Chromatography separates the components of a mixture based on their different affinities for a stationary phase and a mobile phase. By carefully selecting the appropriate chromatographic conditions, pure astaxanthin can be obtained. This pure astaxanthin powder not only meets the high - quality requirements of domestic markets but also has the potential to be exported.

6. Market Potential

With the increasing global demand for natural and organic health products, an organic astaxanthin powder factory has a great opportunity to contribute to the health and well - being of consumers around the world. In the dietary supplement market, astaxanthin is being increasingly recognized for its potential health benefits, such as improving eye health, reducing inflammation, and enhancing immune function. In the cosmetics industry, it is used in anti - aging products due to its antioxidant properties that can help protect the skin from damage caused by environmental factors. Moreover, in the food industry, it can be used as a natural colorant in addition to its potential health - promoting properties.

7. Quality Control and Assurance

To ensure the high quality of the organic astaxanthin powder, the factory has strict quality control and assurance measures in place. These include regular testing of the raw materials, intermediate products, and the final powder. Testing may involve analyzing the astaxanthin content, purity, and the presence of any contaminants. The factory also adheres to international and national quality standards and regulations to ensure that its products are safe and of high quality. For example, in some countries, there are specific regulations regarding the use of solvents in the extraction process and the purity of the final product.

8. Research and Development

The organic astaxanthin powder factory also invests in research and development. This is important for several reasons. Firstly, it helps to improve the production efficiency of astaxanthin. Researchers may look for ways to optimize the cultivation conditions, extraction methods, or purification processes to reduce costs and increase yields. Secondly, R & D can lead to the discovery of new applications for astaxanthin. For example, new research may uncover additional health benefits of astaxanthin, which can open up new markets for the factory's products. Additionally, R & D can also help the factory stay ahead of its competitors by developing innovative products or production techniques.

9. Environmental Considerations

Since the factory's production is centered around microalgae cultivation, there are certain environmental considerations. Microalgae cultivation can have a positive impact on the environment as it can be used for carbon dioxide sequestration. The microalgae absorb carbon dioxide during photosynthesis, which can help to reduce greenhouse gas emissions. However, the factory also needs to ensure that its operations do not cause any negative environmental impacts, such as water pollution. This may involve proper treatment of the waste water generated during the cultivation and extraction processes to ensure that it meets environmental regulations.

10. Conclusion

In conclusion, an organic astaxanthin powder factory is a key player in the production and supply of this valuable antioxidant. Through sustainable production methods, strict quality control, and continuous research and development, the factory can produce high - quality astaxanthin powder that has the potential to meet the growing global demand for natural and organic health products. At the same time, the factory also needs to be aware of environmental considerations to ensure that its operations are sustainable in the long run.

FAQ:

What are the key factors in the selection of microalgae strains for astaxanthin production?

The key factors include the strain's ability to produce high amounts of astaxanthin, its adaptability to the cultivation environment such as temperature and light conditions in the factory, and its resistance to diseases and contaminants. Also, the growth rate of the strain is important as a faster - growing strain can lead to more efficient production.

How does the factory ensure the sustainable production of organic astaxanthin powder?

The factory ensures sustainable production in several ways. Firstly, it uses environmentally friendly cultivation methods for the microalgae. This may include using renewable energy sources for maintaining the cultivation environment. Also, the waste management during the extraction and purification processes is carefully controlled to minimize environmental impact. Moreover, the selection of microalgae strains is also done with an eye on sustainability, choosing strains that can be cultivated without depleting natural resources.

What are the main challenges in the extraction process of astaxanthin?

The main challenges in the extraction process include separating astaxanthin from other components in the microalgae without damaging its antioxidant properties. The extraction has to be highly efficient as astaxanthin is present in relatively small amounts in the microalgae. Also, the cost - effectiveness of the extraction technology is a challenge, as using advanced but expensive technologies may not be viable for large - scale production. Additionally, ensuring the purity of the extracted astaxanthin is difficult as there are many similar - looking substances in the microalgae.

How is the quality of the organic astaxanthin powder controlled in the factory?

The quality of the organic astaxanthin powder is controlled through multiple steps. During the cultivation of microalgae, strict monitoring of environmental conditions and nutrient supply ensures that the source material is of high quality. In the extraction and purification processes, quality control tests are carried out at various stages to check for purity and antioxidant activity. After the powder is obtained, final quality checks are made to ensure it meets both domestic and international standards for organic products.

What are the potential applications of the organic astaxanthin powder produced by the factory?

The organic astaxanthin powder has a wide range of potential applications. It is used in the health and wellness industry as a dietary supplement due to its antioxidant properties, which can help in reducing oxidative stress in the body. In the cosmetic industry, it can be added to skincare products for its anti - aging benefits. It may also find applications in the food and beverage industry as a natural colorant and antioxidant.

Related literature

- Production of Astaxanthin from Microalgae: Current State and Perspectives"

- "Organic Astaxanthin: Properties, Sources and Applications"

- "Sustainable Production of Astaxanthin in Algae - based Systems"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

The best lemon juice powder in nature.

2024-12-02

-

Organic Vitamin K2 Powder Suppliers

2024-12-02

-

Bulk purchase of L - tyrosine.

2024-12-02

-

Vitamin K2 Manufacturers

2024-12-02

-

100% Pure Natural Rutin.

2024-12-02

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-02

-

Purple Sweet Potato Extract

2024-12-02

-

Acerola Juice Powder

2024-12-02

-

Black Pepper Extract

2024-12-02

-

Boswellia Serrata Extract

2024-12-02

-

White Willow Bark Extract

2024-12-02

-

Propolis Extract Powder

2024-12-02

-

Kelp Extract Powder

2024-12-02

-

Maca Extract

2024-12-02

-

Shikonin

2024-12-02

-

Chaste Berry Extract

2024-12-02