- 0086-571-85302990

- sales@greenskybio.com

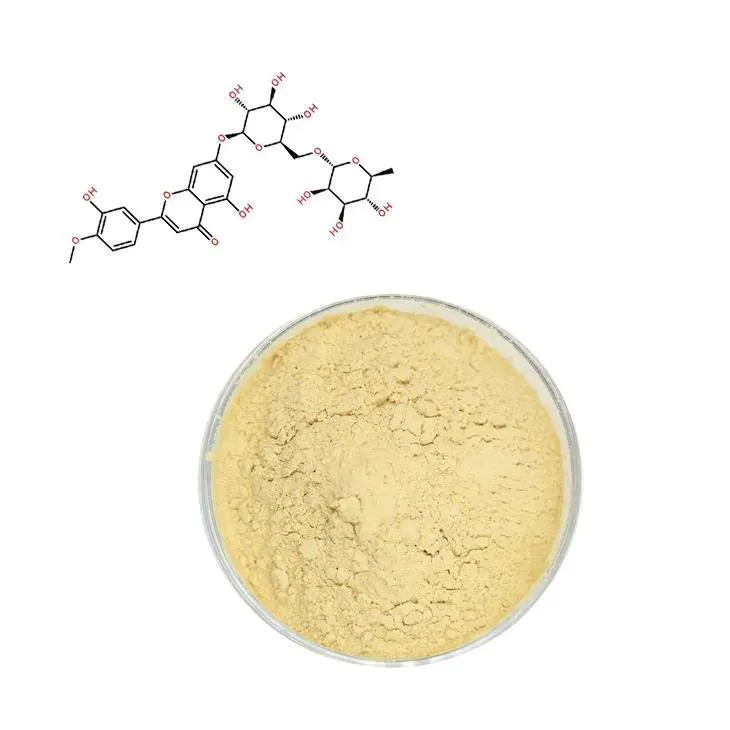

The process of extracting diosmetin hesperetin aglycone from diosmin.

2024-12-02

1. Introduction

Diosmin is a flavonoid that has attracted significant attention due to its various potential health benefits. It is found in many plant sources. The extraction of diosmetin from Diosmin is a crucial process as diosmetin has its own unique properties and potential applications, especially in the fields of antioxidant, anti - inflammatory, and anti - cancer research. This article will provide an in - depth exploration of the entire process of extracting diosmetin from Diosmin.

2. Source Identification and Collection

The first step in the extraction of diosmetin from diosmin is the identification and collection of appropriate sources rich in diosmin.

2.1 Plant - based Sources

Most diosmin - containing sources are plant - based. For example, citrus fruits are well - known sources of diosmin. The peel of citrus fruits, such as oranges and lemons, often contains a relatively high amount of diosmin.

- The quality of these plant - based sources can vary significantly. Factors such as the variety of the plant, the growing conditions (including soil quality, climate, and water availability), and the harvesting time can all affect the diosmin content.

- It is essential to select high - quality plant materials to ensure a sufficient amount of diosmin for the extraction process. This may involve careful sourcing from reliable suppliers or even the cultivation of specific plant varieties under controlled conditions.

3. Extraction of Diosmin

Once the appropriate sources are identified and collected, the next step is to extract diosmin from the plant material.

3.1 Solvent Selection

Different solvents can be used for the extraction, and the choice of solvent is a critical factor.

- Solubility of Diosmin: The solvent should have a good solubility for diosmin to ensure effective extraction. For example, some organic solvents like ethanol and methanol have been found to be effective in dissolving diosmin. Ethanol is often preferred in some cases due to its relatively lower toxicity compared to other solvents.

- Cost: Cost - effectiveness is also an important consideration. Solvents that are too expensive may not be practical for large - scale extraction processes. For instance, while some high - performance solvents may have excellent solubility properties, their high cost may limit their use.

- Environmental Impact: In today's context, the environmental impact of the solvent is also a key factor. Solvents that are more environmentally friendly, such as those that are biodegradable or have a lower potential for environmental pollution, are preferred.

3.2 Solvent Extraction Process

After selecting the appropriate solvent, the solvent extraction process can be carried out.

- The plant material is typically ground into a fine powder to increase the surface area available for extraction. This allows the solvent to come into better contact with the diosmin - containing components within the plant material.

- The powdered plant material is then mixed with the solvent in a suitable container. The mixture is usually stirred or shaken for a certain period to ensure thorough mixing and extraction.

- After the extraction period, the mixture is filtered to separate the liquid extract (containing diosmin) from the solid residue of the plant material.

4. Conversion of Diosmin to Diosmetin

Once diosmin is successfully extracted, the next crucial step is to convert it into diosmetin.

4.1 Acid Hydrolysis

Acid hydrolysis is a traditional method for this conversion.

- By adding an appropriate acid, such as hydrochloric acid or sulfuric acid, the glycosidic link in diosmin can be cleaved. This reaction breaks down the diosmin molecule in a way that can lead to the formation of diosmetin.

- However, acid hydrolysis is a relatively harsh method. It may generate by - products and requires careful post - treatment to remove acid residues. The presence of acid residues can affect the quality and purity of the final product. For example, residual acid may cause corrosion of equipment during subsequent handling or may interfere with the biological activities of the extracted diosmetin.

4.2 Enzyme Hydrolysis

In contrast to acid hydrolysis, enzyme hydrolysis is a more biocompatible approach.

- Specific enzymes can be used to target the glycosidic bond in diosmin. For example, glycosidase enzymes can be employed for this purpose. These enzymes are highly specific and can selectively break the glycosidic bond without causing excessive damage to other parts of the molecule.

- However, enzyme hydrolysis also has its challenges. Maintaining the stability and activity of the enzymes throughout the process is crucial. Enzyme activity can be affected by factors such as temperature, pH, and the presence of inhibitors. Therefore, careful control of the reaction conditions is required to ensure the effectiveness of enzyme hydrolysis.

5. Purification of Diosmetin

After the hydrolysis step, whether it is acid hydrolysis or enzyme hydrolysis, purification steps are essential to obtain pure diosmetin.

5.1 Crystallization

In some cases, crystallization can be used for purification.

- If the reaction mixture contains a relatively high concentration of diosmetin and the conditions are favorable, diosmetin may crystallize out of the solution. This process can be promoted by adjusting factors such as temperature and solvent composition.

- However, crystallization may not be sufficient for complex mixtures. If there are other impurities with similar solubility properties to diosmetin, they may co - crystallize or prevent the proper crystallization of diosmetin.

5.2 Chromatographic Methods

For more complex mixtures, chromatographic methods are more effective for purifying diosmetin.

- High - performance liquid chromatography (HPLC) is one of the most commonly used chromatographic techniques. HPLC can separate diosmetin from other components in the mixture based on differences in their chemical properties, such as polarity and molecular size. It offers high resolution and can accurately purify diosmetin to a high degree of purity.

- Other chromatographic methods, such as column chromatography, can also be used depending on the specific requirements of the purification process. Column chromatography can be a more cost - effective option for some applications, especially when dealing with relatively large amounts of sample.

6. Conclusion

The entire process of extracting diosmetin from diosmin is a complex but crucial one. Starting from the identification and collection of suitable sources, through the extraction of diosmin, the conversion to diosmetin, and finally the purification of diosmetin, each step has its own challenges and considerations. The successful extraction and purification of diosmetin are important for exploring its potential applications in areas such as antioxidant, anti - inflammatory, and anti - cancer research. Continued research in this area is expected to improve the extraction efficiency, reduce costs, and enhance the purity of the final product, thereby unlocking the full potential of diosmetin.

FAQ:

What are the common sources for diosmin extraction?

Common sources for diosmin extraction are often plant - based. However, the quality and diosmin content in these plant sources can vary.

How to choose the solvent for diosmin extraction?

The choice of solvent for diosmin extraction depends on several factors. Solubility of diosmin, cost, and environmental impact are important considerations. Different solvents are tested to find the most suitable one for isolating diosmin from the complex plant material.

What are the differences between acid hydrolysis and enzyme hydrolysis in the conversion from diosmin to diosmetin?

Acid hydrolysis is a traditional method. By adding an appropriate acid, the glycosidic link in diosmin can be cleaved. But it is a harsh method that may need careful post - treatment to remove acid residues. Enzyme hydrolysis is a more biocompatible approach. Specific enzymes can be used to target the glycosidic bond, yet enzyme stability and activity need to be maintained throughout the process.

Why are purification steps necessary after hydrolysis?

After hydrolysis, purification steps are necessary because the resulting product may be impure. Crystallization can be used in some cases to obtain pure diosmetin. For more complex mixtures, chromatographic methods like high - performance liquid chromatography (HPLC) are more effective.

What are the potential applications of diosmetin?

Diosmetin has potential applications in areas such as antioxidant, anti - inflammatory, and anti - cancer research. Extracting diosmetin from diosmin is crucial for exploring these potential applications.

Related literature

- Diosmetin: A Promising Flavonoid with Multiple Health - Promoting Properties"

- "The Chemistry and Bioactivity of Diosmin and Diosmetin: An Overview"

- "Extraction and Characterization of Diosmetin from Natural Sources"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

The best lemon juice powder in nature.

2024-12-02

-

Organic Vitamin K2 Powder Suppliers

2024-12-02

-

Bulk purchase of L - tyrosine.

2024-12-02

-

Vitamin K2 Manufacturers

2024-12-02

-

100% Pure Natural Rutin.

2024-12-02

-

Chinese Citrus Bioflavonoid Suppliers.

2024-12-02

-

Mulberry Extract

2024-12-02

-

Longan Extract

2024-12-02

-

Saponin Extract

2024-12-02

-

Curcumin

2024-12-02

-

Tongkat Ali Extract Powder

2024-12-02

-

Yam Extract

2024-12-02

-

Genistein

2024-12-02

-

Almond Extract Powder

2024-12-02

-

Golden Seal Extract

2024-12-02

-

Red Wine Extract

2024-12-02