- 0086-571-85302990

- sales@greenskybio.com

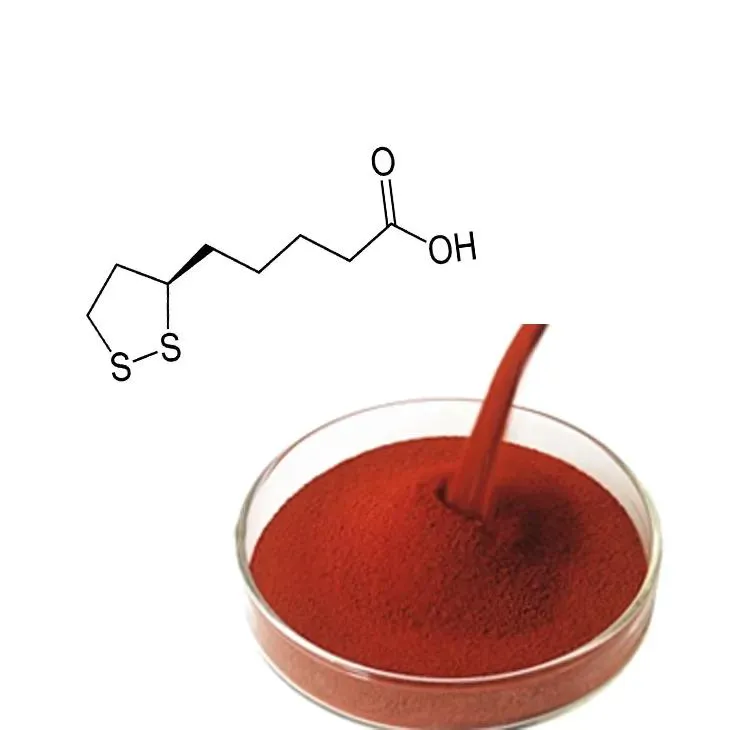

The process of extracting high - purity astaxanthin from astaxanthin.

2024-11-29

1. Introduction

Astaxanthin is a powerful antioxidant that has gained significant attention in recent years due to its numerous potential health benefits and applications in various industries such as cosmetics and health supplements. High - purity Astaxanthin is especially desirable as it can offer more effective and targeted functions. The extraction process of high - purity Astaxanthin is a complex but crucial procedure that involves multiple steps and techniques.

2. Source Material Selection

2.1 Microalgae as a Preferred Source

When it comes to extracting astaxanthin, the choice of source material is of utmost importance. Microalgae have emerged as a popular choice for several reasons. Microalgae are capable of producing astaxanthin in relatively high concentrations compared to other sources. They can be cultivated in a controlled environment, which allows for better regulation of the production process. For example, Haematococcus pluvialis is a well - known microalgae species that is rich in astaxanthin. It can accumulate astaxanthin up to several percent of its dry weight under certain stress conditions such as high light intensity and nutrient deficiency.

3. Preparation of Source Material

3.1 Drying of Microalgae

Once the microalgae are collected, they often need to be dried before the extraction process. Drying serves multiple purposes. Firstly, it helps in reducing the moisture content, which can interfere with the extraction process. Moisture can dilute the solvents used for extraction and may also lead to the growth of microorganisms, which can degrade the astaxanthin. There are different drying methods available, such as air drying, freeze - drying, and spray - drying. Air drying is a simple and cost - effective method, but it may take a longer time and may not be suitable for large - scale industrial production. Freeze - drying can preserve the quality of the microalgae better as it minimizes the damage to the cellular structure, but it is relatively expensive. Spray - drying is a more rapid process and is often used in industrial settings as it can handle large quantities of microalgae efficiently.

4. Extraction Methods

4.1 Solvent Extraction

One of the most common methods for extracting astaxanthin from microalgae is solvent extraction. Different solvents have different extraction capabilities and selectivity. For example, organic solvents like hexane, ethanol, and acetone are often used. Hexane is a non - polar solvent that is good at extracting non - polar compounds such as lipids along with astaxanthin. However, it has some environmental and safety concerns due to its flammability and potential toxicity. Ethanol is a more polar solvent, which can selectively extract astaxanthin while leaving behind some of the unwanted lipids. It is also considered a "greener" solvent compared to hexane as it is less toxic and more biodegradable. Acetone has intermediate polarity and can also be effective in extracting astaxanthin. The choice of solvent depends on factors such as the desired purity of astaxanthin, cost, and environmental considerations.4.2 Supercritical Fluid Extraction

Another extraction method that has been gaining attention is supercritical fluid extraction. In this method, a supercritical fluid, such as supercritical carbon dioxide (scCO₂), is used as the extractant. Supercritical fluids have properties between those of a gas and a liquid. scCO₂ has the advantage of being non - toxic, non - flammable, and having a relatively low critical temperature and pressure. It can selectively extract astaxanthin from the microalgae matrix. Moreover, the extraction can be easily controlled by adjusting parameters such as pressure and temperature. However, the equipment required for supercritical fluid extraction is relatively expensive, which may limit its widespread use in some small - scale operations.5. Purification of the Extract

5.1 Membrane Separation

After extraction, the extract contains not only astaxanthin but also other components. To isolate high - purity astaxanthin, membrane separation can be used as an initial purification step. Membrane separation is based on the principle of size exclusion. Different membranes with different pore sizes can be used to separate larger molecules (such as proteins and polysaccharides) from smaller molecules like astaxanthin. For example, ultrafiltration membranes can retain larger molecules while allowing astaxanthin to pass through. This helps in reducing the complexity of the extract and preparing it for further purification steps.5.2 Chromatography

Chromatography is a powerful technique for purifying astaxanthin to high purity. There are different types of chromatography that can be used, such as high - performance liquid chromatography (HPLC) and column chromatography. In HPLC, a liquid mobile phase is used to carry the sample through a column packed with a stationary phase. The different components in the sample, including astaxanthin, interact differently with the stationary and mobile phases, resulting in their separation. Column chromatography is a more traditional method, where a column is filled with a suitable adsorbent material. The extract is loaded onto the column, and different components are eluted at different times depending on their affinity for the adsorbent. Through careful optimization of the chromatography conditions, high - purity astaxanthin can be obtained.6. Characterization and Quality Control

Once the high - purity astaxanthin is obtained, it is essential to characterize it and perform quality control. Characterization techniques such as spectroscopy (e.g., ultraviolet - visible spectroscopy, infrared spectroscopy) can be used to determine the chemical structure and purity of astaxanthin. Quality control measures include checking for the presence of impurities, ensuring the correct isomeric form of astaxanthin (as there are different isomers with different biological activities), and verifying the stability of the astaxanthin product. These steps are crucial to ensure that the high - purity astaxanthin meets the requirements for its intended applications in cosmetics, health supplements, and other industries.

7. Conclusion

The extraction of high - purity astaxanthin from astaxanthin is a multi - step process that requires careful consideration of the source material, extraction methods, and purification techniques. Microalgae are a promising source of astaxanthin, and through proper drying and subsequent extraction using solvents or supercritical fluids, followed by purification steps such as membrane separation and chromatography, high - purity astaxanthin can be obtained. Quality control and characterization are also important aspects to ensure the final product is suitable for various applications. As the demand for astaxanthin in different industries continues to grow, further research and development in the extraction and purification processes are likely to occur to improve efficiency, reduce costs, and enhance the quality of high - purity astaxanthin.

FAQ:

What are the common source materials for astaxanthin extraction?

Microalgae are a popular source material for astaxanthin extraction. However, astaxanthin can also be sourced from other organisms such as some crustaceans, but microalgae are often preferred due to their relatively high astaxanthin content and ease of large - scale cultivation.

Why is solvent extraction used in astaxanthin extraction?

Solvent extraction is used because different solvents have the ability to dissolve astaxanthin from the source material. The solvents can selectively dissolve astaxanthin along with other components present in the source, which is the first step in separating astaxanthin from the rest of the material. Different solvents offer different extraction capabilities and selectivity, allowing for optimization of the extraction process.

How does membrane separation contribute to obtaining high - purity astaxanthin?

Membrane separation helps in the process of obtaining high - purity astaxanthin by initially separating larger and smaller molecules. This is important as the extract after solvent extraction contains not only astaxanthin but also other components. Membrane separation can be used as a pre - purification step to separate out some of the unwanted larger or smaller molecules, making the subsequent purification steps such as chromatography more effective.

What are the applications of high - purity astaxanthin?

High - purity astaxanthin has great value in various industries. In the cosmetics industry, it is used for its antioxidant properties which can help in anti - aging and skin protection. In the health supplements industry, it is believed to have benefits for eye health, joint health, and as a general antioxidant supplement to boost the immune system.

What are the challenges in extracting high - purity astaxanthin?

One of the challenges is the presence of other components in the source material that need to be separated from astaxanthin. This requires careful selection of extraction and purification methods. Another challenge is the cost - effectiveness of the process, as some extraction and purification techniques can be expensive. Also, maintaining the stability of astaxanthin during the extraction and purification processes is crucial as it is a relatively unstable compound.

Related literature

- High - Purity Astaxanthin Extraction: A Review of Current Techniques"

- "Advances in Astaxanthin Extraction from Microalgae for High - Purity Applications"

- "Solvent - Based Extraction of Astaxanthin: Optimization for High Purity"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

The best lemon juice powder in nature.

2024-11-29

-

Organic Vitamin K2 Powder Suppliers

2024-11-29

-

Bulk purchase of L - tyrosine.

2024-11-29

-

Vitamin K2 Manufacturers

2024-11-29

-

100% Pure Natural Rutin.

2024-11-29

-

Chinese Citrus Bioflavonoid Suppliers.

2024-11-29

-

Phyllanthus Emblica Extract

2024-11-29

-

Oyster Mushroom Extract Powder

2024-11-29

-

Gynostemma pentaphyllum extract

2024-11-29

-

Curcumin Extract

2024-11-29

-

Longan Extract

2024-11-29

-

Acerola Extract

2024-11-29

-

Chia Seed Powder

2024-11-29

-

Sugarcane Extract

2024-11-29

-

Lavender Extract

2024-11-29

-

Alisma Extract

2024-11-29