- 0086-571-85302990

- sales@greenskybio.com

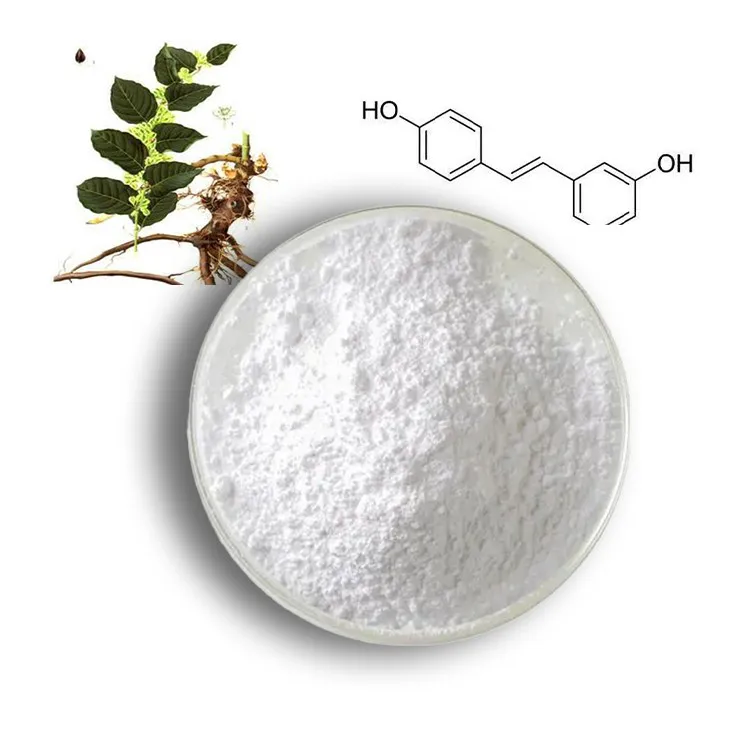

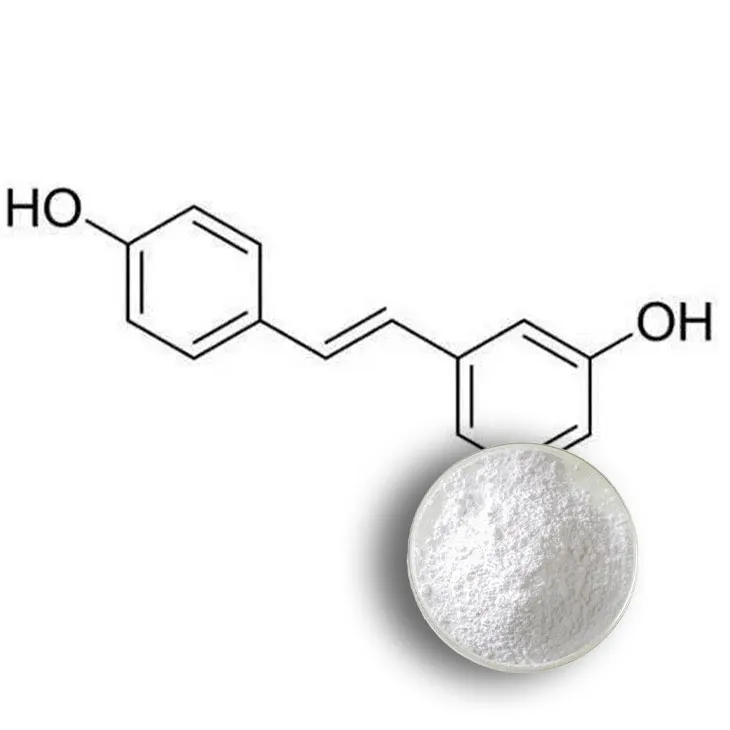

The process of extracting high - purity resveratrol from resveratrol extract.

2024-11-30

1. Introduction

Resveratrol, a natural phenolic compound, has gained significant attention in various fields such as medicine, cosmetics, and food due to its antioxidant, anti - inflammatory, and anti - aging properties. However, the extraction of high - purity resveratrol from Resveratrol extracts is a complex process that requires careful consideration of multiple factors. This article aims to explore the process of extracting high - purity resveratrol, taking into account cost - effectiveness, environmental impact, and product quality control.

2. Initial Extraction of Resveratrol

2.1. Source Selection

The first step in extracting resveratrol is the selection of the source material. Resveratrol can be found in various plants, with grapes, especially the skins and seeds, being one of the most common sources. Grape skins are rich in resveratrol, and they are often a by - product of the winemaking process. Other sources include peanuts, berries, and some medicinal plants. When choosing the source, factors such as the resveratrol content, availability, and cost need to be considered.

2.2. Extraction Methods

There are several methods for extracting resveratrol from the source material:

- Solvent Extraction: This is one of the most commonly used methods. Organic solvents such as ethanol, methanol, and ethyl acetate are often used. For example, in the case of grape skins, the material is soaked in the solvent for a certain period. The solvent then dissolves the resveratrol along with other compounds. However, the choice of solvent is crucial as it can affect the purity of the final product and also has environmental implications. Ethanol is often preferred as it is relatively safe and has a lower environmental impact compared to some other solvents.

- Supercritical Fluid Extraction (SFE): This method uses supercritical fluids, usually carbon dioxide. Supercritical carbon dioxide has properties between a gas and a liquid, which allows it to effectively extract resveratrol. The advantage of SFE is that it can produce a cleaner extract with less solvent residue. However, the equipment for SFE is more expensive, which can increase the cost of the extraction process.

3. Purification of Resveratrol extract

3.1. Filtration

After the initial extraction, the resveratrol - containing extract needs to be filtered. Filtration helps to remove solid particles, such as plant debris, that may be present in the extract. There are different types of filtration methods, including:

- Gravity Filtration: This is a simple method where the extract is passed through a filter paper or a porous medium under the force of gravity. It is suitable for removing larger particles but may not be very effective for fine particles.

- Vacuum Filtration: In this method, a vacuum is applied to speed up the filtration process. It can be more effective in removing particles compared to gravity filtration, especially for semi - solid extracts.

3.2. Chromatographic Separation

Chromatographic techniques play a crucial role in purifying resveratrol to a high degree of purity.

- Column Chromatography: In column chromatography, the Resveratrol extract is loaded onto a column filled with a stationary phase, such as silica gel or alumina. A mobile phase, usually an organic solvent or a solvent mixture, is then passed through the column. Different compounds in the extract will interact differently with the stationary and mobile phases, resulting in their separation. Resveratrol can be eluted from the column at a specific time depending on its interaction characteristics. However, column chromatography can be time - consuming and requires careful optimization of the column packing and solvent system.

- High - Performance Liquid Chromatography (HPLC): HPLC is a more advanced chromatographic technique. It offers high resolution and can accurately separate resveratrol from other closely related compounds. The mobile phase is pumped at a high pressure through a column filled with a very fine stationary phase. The detector can accurately identify and quantify the resveratrol in the eluent. Although HPLC is highly effective, the equipment is expensive, and the running costs are relatively high.

4. Quality Control in the Extraction Process

4.1. Purity Analysis

To ensure the high - purity of resveratrol, various analytical methods are used for purity analysis.

- High - Performance Liquid Chromatography - Mass Spectrometry (HPLC - MS): This technique combines the separation power of HPLC with the identification ability of mass spectrometry. It can accurately determine the purity of resveratrol by identifying its molecular mass and fragmentation pattern. HPLC - MS is a very sensitive method and can detect even trace amounts of impurities.

- Nuclear Magnetic Resonance (NMR) Spectroscopy: NMR can provide detailed information about the molecular structure of resveratrol. By analyzing the NMR spectra, the purity and chemical structure integrity of resveratrol can be determined. However, NMR spectroscopy requires relatively large sample amounts and more complex sample preparation compared to HPLC - MS.

4.2. Contaminant Detection

Detecting contaminants in the resveratrol extract is also an important part of quality control.

- Heavy Metal Detection: Since resveratrol may be used in food and pharmaceutical applications, the presence of heavy metals such as lead, mercury, and cadmium needs to be monitored. Atomic absorption spectroscopy (AAS) or inductively coupled plasma - mass spectrometry (ICP - MS) can be used to detect heavy metals at very low concentrations.

- Residual Solvent Analysis: As solvents are used in the extraction process, it is necessary to check for residual solvents in the final product. Gas chromatography (GC) is a common method for analyzing residual solvents. The levels of residual solvents should be within the acceptable limits set by regulatory agencies.

5. Cost - Effectiveness Considerations

Cost - effectiveness is an important factor in the extraction of high - purity resveratrol.

5.1. Raw Material Cost

The cost of the source material can significantly impact the overall cost of the extraction process. As mentioned earlier, different sources of resveratrol have different costs. For example, grape skins, which are a by - product of the winemaking industry, may be relatively inexpensive compared to some rare medicinal plants. However, the availability and quality of the raw material also need to be considered. If the raw material has a low resveratrol content, more material may be required, which can increase the cost.

5.2. Extraction and Purification Costs

The costs associated with extraction and purification methods also play a crucial role.

- Solvent Extraction Costs: The cost of solvents, such as ethanol or methanol, needs to be considered. Additionally, the energy required for the extraction process, such as heating or agitation, also adds to the cost. However, solvent extraction is generally a relatively inexpensive method compared to some others.

- Supercritical Fluid Extraction Costs: Although SFE can produce a high - quality extract, the high cost of the equipment and the need for specialized operation can make it more expensive. The cost of carbon dioxide as the supercritical fluid also needs to be considered.

- Chromatographic Purification Costs: Column chromatography and HPLC are both costly processes. The cost of the stationary and mobile phases, as well as the maintenance and operation of the equipment, can be significant. However, these methods are necessary to achieve high - purity resveratrol.

6. Environmental Impact

The extraction process of high - purity resveratrol should also consider its environmental impact.

6.1. Solvent Usage and Disposal

In solvent extraction methods, the choice of solvent and its proper disposal are important environmental considerations. Organic solvents can be harmful to the environment if not disposed of properly. Ethanol, for example, is relatively biodegradable compared to some other solvents. However, large - scale use of solvents still requires proper management to minimize environmental pollution.

6.2. Energy Consumption

Energy consumption in the extraction and purification processes also has an environmental impact. High - energy - consuming methods such as supercritical fluid extraction and HPLC may contribute to a higher carbon footprint. Therefore, efforts should be made to optimize the processes to reduce energy consumption, for example, by using more energy - efficient equipment or optimizing the operating conditions.

7. Conclusion

The extraction of high - purity resveratrol from resveratrol extracts is a multi - step process that involves initial extraction, purification, quality control, cost - effectiveness considerations, and environmental impact assessment. Each step in the process has its own challenges and requirements. The choice of extraction and purification methods should be carefully balanced to achieve high - quality, high - purity resveratrol while also considering cost and environmental factors. With the increasing demand for high - purity resveratrol in various fields, continuous research and improvement in the extraction process are necessary to meet the market needs and regulatory requirements.

FAQ:

Q1: What are the main methods for the initial extraction of resveratrol from its extract?

There are several common methods for the initial extraction. One is solvent extraction, where solvents like ethanol are often used. The principle is that resveratrol has certain solubility in these solvents. Another method could be supercritical fluid extraction, which uses supercritical CO2. It has the advantages of being relatively clean and can effectively extract resveratrol from the extract while reducing the extraction of some unwanted substances.

Q2: How can we ensure cost - effectiveness during the extraction process?

To ensure cost - effectiveness, firstly, the selection of raw materials is crucial. Using high - quality but cost - effective resveratrol extracts as starting materials can save costs. In the extraction process, optimizing the extraction conditions such as solvent concentration, extraction time and temperature can improve the extraction efficiency and reduce the consumption of resources. For example, finding the optimal ethanol concentration for solvent extraction can not only ensure a high extraction rate but also save on solvent usage. Also, recycling solvents when possible can significantly cut down costs.

Q3: What are the key factors in product quality control during the extraction of high - purity resveratrol?

During the extraction, several key factors are involved in product quality control. Purity analysis is essential. High - performance liquid chromatography (HPLC) is often used to accurately measure the purity of resveratrol. Contamination control is also crucial. This includes preventing the introduction of impurities during the extraction process, such as from the extraction equipment or the solvents used. Additionally, strict control of the extraction conditions to ensure consistent product quality is necessary. For example, any deviation in temperature or extraction time may affect the purity and quality of the final resveratrol product.

Q4: How does the extraction process impact the environment?

The extraction process can have both positive and negative environmental impacts. For solvent extraction, if the solvents are not properly managed, they can cause pollution. For example, if ethanol is not recycled or disposed of properly, it can contaminate water sources. However, methods like supercritical fluid extraction, which uses CO2, can be more environmentally friendly as CO2 is a non - toxic and relatively easily recyclable substance. To reduce the environmental impact, waste management during the extraction process should be emphasized, such as proper treatment of waste solvents and other by - products.

Q5: What are the final purification steps for obtaining high - purity resveratrol?

The final purification steps often involve techniques such as crystallization and chromatography. Crystallization can be used to separate resveratrol from other substances based on its solubility characteristics. Chromatography, especially preparative chromatography, can further purify resveratrol by separating it from remaining impurities. For example, silica gel chromatography can be used to selectively adsorb and separate different components, allowing for the isolation of high - purity resveratrol.

Related literature

- Advances in Resveratrol Extraction and Purification Techniques"

- "Optimization of Resveratrol Extraction from Natural Sources"

- "High - Purity Resveratrol: Production and Quality Control"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

The best lemon juice powder in nature.

2024-11-30

-

Organic Vitamin K2 Powder Suppliers

2024-11-30

-

Bulk purchase of L - tyrosine.

2024-11-30

-

Vitamin K2 Manufacturers

2024-11-30

-

100% Pure Natural Rutin.

2024-11-30

-

Chinese Citrus Bioflavonoid Suppliers.

2024-11-30

-

Phellodendron Extract

2024-11-30

-

Aguaje Extract

2024-11-30

-

Grape Leaf Extract

2024-11-30

-

Licorice Root Extract Powder

2024-11-30

-

Nutmeg Extract

2024-11-30

-

Dan Shen Root Extract/Salvia Root Extract

2024-11-30

-

Alisma Extract

2024-11-30

-

Grape Seed Extract

2024-11-30

-

Bilberry Extract

2024-11-30

-

Hawthorn powder

2024-11-30