- 0086-571-85302990

- sales@greenskybio.com

8 Best Diosmin Manufacturers

2024-12-30

1. Introduction

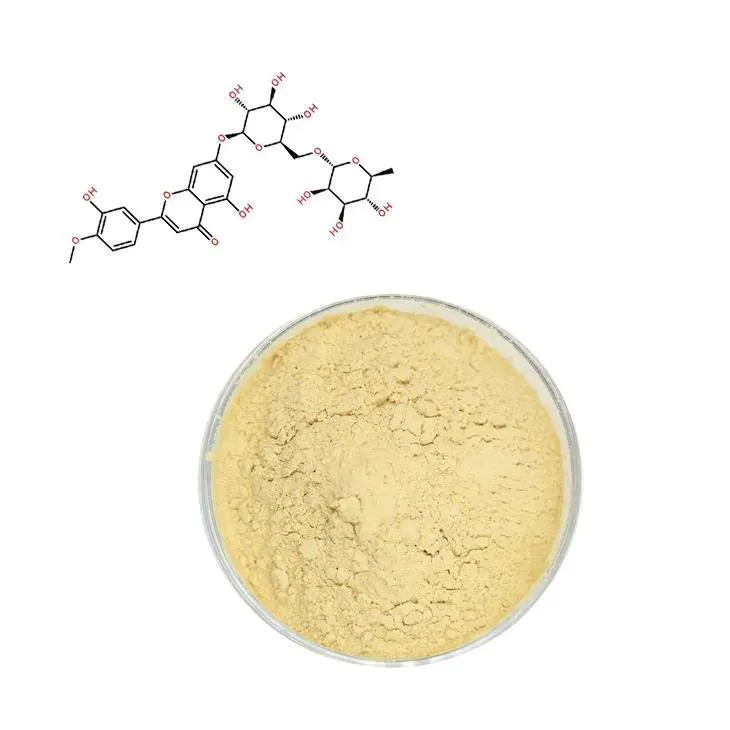

In the pharmaceutical realm, Diosmin is a compound of great significance, finding diverse applications. It is essential for various medical treatments, especially in cases related to venous insufficiency. When evaluating the best Diosmin manufacturers, a multi - faceted approach is necessary.

2. Key Factors in Evaluating Diosmin Manufacturers

2.1 Quality Control

Quality control stands as one of the most crucial aspects. Reputable diosmin manufacturers are committed to adhering to strict international standards. This ensures that the diosmin products they produce possess the required purity and efficacy. High - quality control measures involve comprehensive testing at every stage of the production process, from raw material sourcing to the final product packaging. For instance, manufacturers need to test for the presence of impurities, ensure accurate dosage levels, and verify the stability of the diosmin compound. By strictly following these standards, they can guarantee that the diosmin supplied to the market is safe and effective for use in medical applications.

2.2 Production Capacity

Another important factor is production capacity. In a market with a high demand for diosmin, larger manufacturers have an edge. They are often better equipped to meet the market requirements more efficiently. A significant production capacity allows them to fulfill large - scale orders promptly, which is especially important for pharmaceutical companies that rely on a consistent supply of diosmin. Moreover, large - scale production can sometimes lead to cost - savings, which can potentially be passed on to the consumers or used for further research and development.

2.3 Research and Development

Some of the top - tier diosmin manufacturers understand the importance of continuous improvement. They invest heavily in research and development (R & D). Through R & D, they strive to enhance the production process. This could involve finding more cost - effective and environmentally friendly ways of synthesizing diosmin. Additionally, they focus on developing new formulations of diosmin. New formulations may offer improved bioavailability, which means that the body can absorb and utilize the diosmin more effectively. This is crucial for optimizing the therapeutic benefits of diosmin in treating various medical conditions.

2.4 Environmental Protection

During the manufacturing process, environmental protection has become a key consideration for many manufacturers. Responsible diosmin manufacturers take steps to minimize their environmental impact. This can include reducing waste generation, conserving energy, and using environmentally friendly solvents and reagents. By implementing these measures, they not only contribute to the global environmental conservation efforts but also enhance their corporate social responsibility profile.

3. Top Diosmin Manufacturers

3.1 Manufacturer A

Manufacturer A has established a strong reputation in the diosmin manufacturing industry. They are known for their stringent quality control procedures. Their production facilities are equipped with state - of - the - art technology that enables them to produce high - purity diosmin. With a significant production capacity, they can meet both domestic and international demands. Their R & D department is constantly exploring ways to improve the product quality and develop new formulations. For example, they have recently been researching on enhancing the solubility of diosmin, which could lead to more effective oral medications. In terms of environmental protection, they have implemented a waste - management system that reduces their overall environmental footprint.

3.2 Manufacturer B

Manufacturer B is another leading player. Their commitment to quality is evident in their adherence to international quality standards. They source their raw materials from reliable suppliers, ensuring the consistency of their diosmin products. Their production capacity has been steadily increasing over the years, allowing them to capture a larger share of the market. In R & D, they are focused on understanding the pharmacokinetics of diosmin better. This research could potentially lead to more personalized treatment regimens. Regarding environmental protection, they use renewable energy sources in part of their manufacturing process, which is a step towards sustainable manufacturing.

3.3 Manufacturer C

Manufacturer C stands out for its comprehensive quality control system. They conduct multiple tests on their diosmin products, including tests for microbiological contamination and chemical stability. Their production capacity is sufficient to meet the demands of the growing pharmaceutical market. In the area of R & D, they are collaborating with academic institutions to study the potential new applications of diosmin. This collaborative approach brings in fresh perspectives and expertise. When it comes to environmental protection, they have introduced a recycling program for their packaging materials, reducing waste and promoting environmental sustainability.

3.4 Manufacturer D

Manufacturer D has a long - standing history in the manufacturing of diosmin. Their quality control is based on a set of in - house standards that are even more stringent than some international requirements. This has earned them the trust of many pharmaceutical companies. Their production capacity is large enough to supply diosmin for both generic and branded medications. In R & D, they are investing in exploring the use of novel technologies such as nanotechnology to improve the delivery of diosmin in the body. For environmental protection, they are constantly looking for ways to reduce their carbon emissions during the production process.

3.5 Manufacturer E

Manufacturer E is renowned for its high - quality diosmin products. Their quality control team is highly trained and uses advanced analytical techniques to ensure product quality. Their production capacity is optimized to ensure timely delivery of orders. In R & D, they are focused on developing diosmin - based combination products. These combination products may offer enhanced therapeutic effects compared to single - ingredient diosmin. In terms of environmental protection, they have implemented a green chemistry approach in their manufacturing process, which aims to minimize the use of hazardous chemicals.

3.6 Manufacturer F

Manufacturer F has made a name for itself in the diosmin market. They have a robust quality control system that monitors every step of the production process. Their production capacity is scalable, allowing them to adapt to market fluctuations. In R & D, they are working on improving the stability of diosmin in different formulations. This could lead to longer - shelf - life products. For environmental protection, they are involved in a reforestation project as part of their corporate social responsibility initiative, offsetting some of their carbon emissions.

3.7 Manufacturer G

Manufacturer G is a relatively new but fast - growing diosmin manufacturer. Despite being new, they have quickly implemented high - quality control standards. Their production capacity is growing steadily, and they are focused on meeting the specific needs of niche markets. In R & D, they are exploring the potential of diosmin in alternative delivery systems such as transdermal patches. For environmental protection, they use biodegradable packaging materials, which is an innovative approach in the industry.

3.8 Manufacturer H

Manufacturer H has a reputation for producing pure and effective diosmin. Their quality control is centered around ensuring the highest level of product purity. Their production capacity is sufficient to support their business operations both locally and globally. In R & D, they are looking into the genetic engineering aspects related to diosmin production, which could potentially revolutionize the production process. In terms of environmental protection, they have installed energy - efficient equipment in their manufacturing facilities to reduce energy consumption.

4. Conclusion

The diosmin manufacturing industry is populated by several excellent manufacturers. Each of the manufacturers mentioned above, namely Manufacturer A - H, has its own strengths in terms of quality control, production capacity, research and development, and environmental protection. These manufacturers play a vital role in providing high - quality diosmin for the treatment of various medical conditions, especially venous insufficiency. As the demand for diosmin continues to grow, it is expected that these manufacturers will continue to innovate and improve, further enhancing the quality and availability of diosmin in the global market.

FAQ:

What are the main factors to consider when choosing a diosmin manufacturer?

When choosing a diosmin manufacturer, the main factors to consider include quality control, production capacity, investment in research and development, and environmental protection during the manufacturing process. Quality control is crucial as reputable manufacturers adhere to strict international standards to ensure the purity and efficacy of their diosmin products. Production capacity matters because larger manufacturers can often meet the high - demand in the market more efficiently. Manufacturers that invest in research and development can improve the production process and develop new formulations, and those that focus on environmental protection also show their responsibility during the manufacturing process.

Why is quality control important for diosmin manufacturers?

Quality control is extremely important for diosmin manufacturers. Diosmin is used for the treatment of various medical conditions like venous insufficiency. If the quality is not well - controlled, the purity and efficacy of the diosmin product may be affected. This could lead to ineffective treatment or even potential harm to patients. Therefore, strict quality control following international standards is necessary to ensure that the diosmin products are of high quality and can be safely used for medical purposes.

How does production capacity of diosmin manufacturers affect the market?

The production capacity of diosmin manufacturers has a significant impact on the market. High - demand for diosmin exists in the market, especially for its applications in treating medical conditions. Larger manufacturers with greater production capacity can meet this demand more efficiently. They are more likely to be able to supply sufficient quantities of diosmin products in a timely manner. This helps to avoid shortages in the market, stabilize prices, and ensure that patients who need diosmin - based treatments can access the products without delay.

What role does research and development play in diosmin manufacturing?

Research and development plays a very important role in diosmin manufacturing. Manufacturers that invest in research and development can work on improving the production process. This may lead to more cost - effective and efficient ways of producing diosmin. They can also develop new formulations of diosmin. New formulations might have enhanced properties such as better bioavailability or improved efficacy, which can further contribute to the development of better treatments for medical conditions related to diosmin use.

Why is environmental protection important for diosmin manufacturers?

Environmental protection is important for diosmin manufacturers for several reasons. Firstly, the manufacturing process may generate waste or emissions that can have a negative impact on the environment. By focusing on environmental protection, manufacturers can reduce these negative impacts. Secondly, in today's world, being environmentally responsible is also a part of corporate social responsibility. It helps to enhance the manufacturer's reputation among consumers and in the industry. Moreover, regulatory requirements may also demand certain environmental standards to be met during the manufacturing of diosmin.

Related literature

- Diosmin: Properties, Production and Therapeutic Applications"

- "Quality Assurance in Diosmin Manufacturing"

- "The Role of Research and Development in the Diosmin Industry"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Hedyotis Diffusa Extract

2024-12-30

-

Eucommia Ulmoides Extract

2024-12-30

-

Artichoke Extract

2024-12-30

-

Moringa powder

2024-12-30

-

Elderberry Extract

2024-12-30

-

Kupilu Extract

2024-12-30

-

Garcinia Cambogia Extract

2024-12-30

-

Ginseng Root Extract

2024-12-30

-

Lycopene

2024-12-30

-

Lily extract

2024-12-30