- 0086-571-85302990

- sales@greenskybio.com

8 Best Resveratrol Extract Manufacturers

2024-12-11

1. Introduction

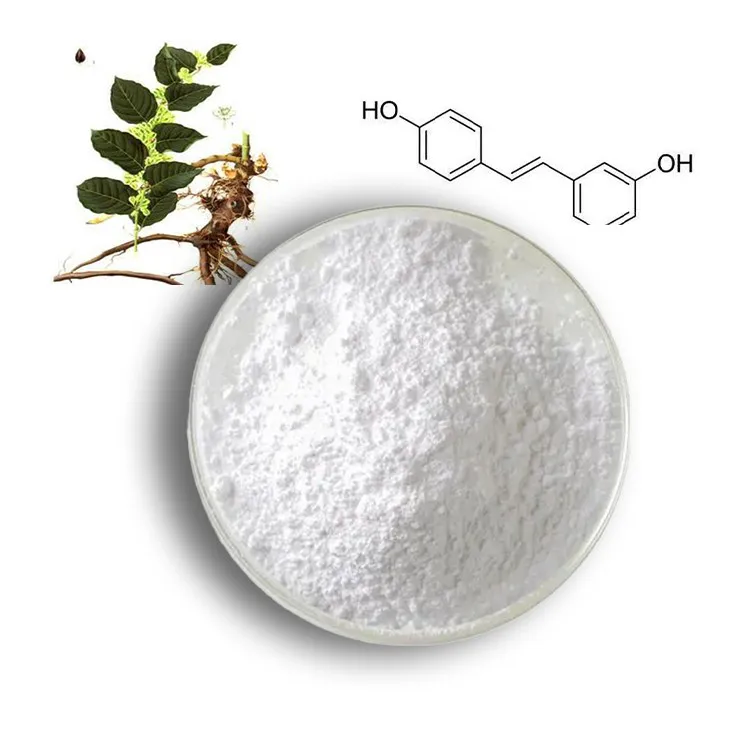

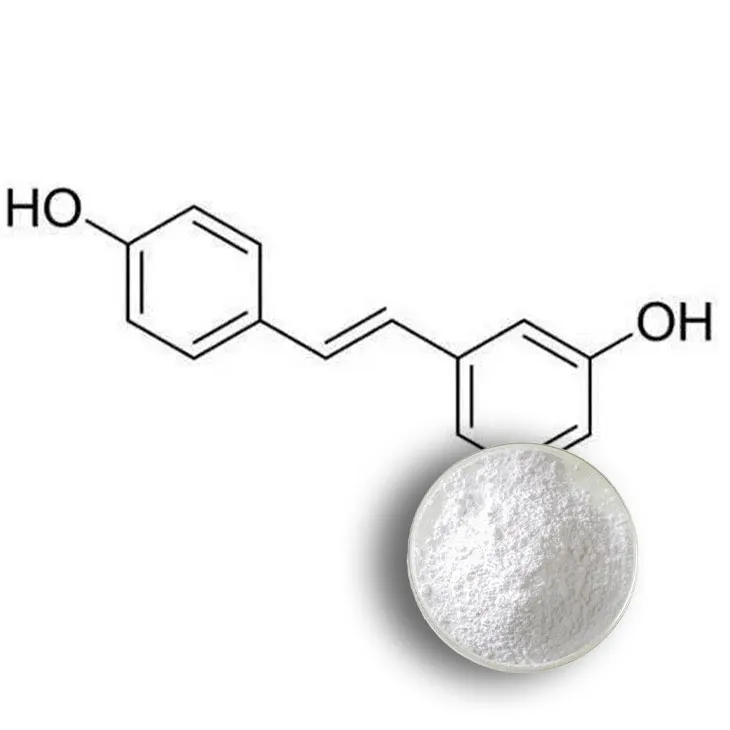

White Resveratrol extract has become a highly sought - after substance in recent years. Its potential health benefits have made it a popular ingredient in the supplement, pharmaceutical, and cosmetic industries. However, the quality of Resveratrol extract can vary significantly depending on the manufacturer. In this article, we will explore eight of the top white Resveratrol extract manufacturers, taking into account factors such as quality control, production capacity, research and development capabilities, and market reputation.

2. Importance of Quality Control

Quality control is paramount when it comes to white resveratrol extract. The best manufacturers follow strict quality assurance procedures throughout the production process.

2.1 Sourcing High - Quality Raw Materials

High - quality raw materials are the foundation of a good resveratrol extract. Reputable manufacturers ensure that they source their raw materials from reliable suppliers. For example, they may look for grapes grown in specific regions known for their high resveratrol content. This attention to the source of raw materials helps to ensure that the final extract is of high quality.

2.2 Advanced Extraction and Purification Techniques

Once the raw materials are sourced, the extraction and purification processes are crucial. The top manufacturers use advanced techniques to extract and purify resveratrol. These techniques not only help to increase the yield of resveratrol but also ensure its purity. For instance, some manufacturers may use supercritical fluid extraction, which is known for its ability to produce a high - quality extract with minimal solvent residue.

2.3 Meeting International Standards

Another aspect of quality control is ensuring that the product meets international standards. This includes standards for purity, safety, and efficacy. Manufacturers need to conduct regular tests to ensure that their resveratrol extract is free from contaminants such as heavy metals, pesticides, and other harmful substances. By meeting these international standards, manufacturers can ensure that their products are acceptable in the global market.

3. Production Capacity

Production capacity is an important factor to consider when choosing a resveratrol extract manufacturer. Manufacturers with large - scale production capabilities offer several advantages.

3.1 Meeting Market Demands

The global demand for resveratrol extract is growing steadily. Manufacturers with large production capacities can meet this growing demand. This is especially important for industries such as the supplement and pharmaceutical industries, where a stable supply is crucial. For example, a large - scale manufacturer can ensure that there is enough resveratrol extract available to meet the needs of various supplement companies that rely on it as an ingredient.

3.2 Competitive Pricing

Larger production volumes often lead to more competitive pricing. Manufacturers can take advantage of economies of scale to reduce the cost per unit of production. This can result in lower prices for the end - user. For instance, a manufacturer that can produce large quantities of resveratrol extract can offer it at a more affordable price compared to a smaller manufacturer with higher per - unit costs.

4. Research and Development Capabilities

Research and development (R & D) play a crucial role in the resveratrol extract manufacturing industry.

4.1 Improving Extraction Methods

Leading manufacturers invest in R & D to improve extraction methods. By constantly researching and developing new extraction techniques, they can increase the efficiency and quality of the extraction process. For example, they may explore new solvents or extraction conditions that can improve the yield and purity of resveratrol extract. This continuous improvement in extraction methods can lead to a better - quality product.

4.2 Enhancing Purity

R & D efforts are also focused on enhancing the purity of the resveratrol extract. Higher - purity extracts are more desirable in the market as they are more likely to be effective. Manufacturers may use advanced purification techniques such as chromatography to remove impurities and increase the purity of the resveratrol extract. This not only improves the quality of the product but also expands its potential applications.

4.3 Exploring New Applications

In addition to improving the extraction and purification processes, manufacturers also invest in R & D to explore new applications of white resveratrol. For example, they may research its potential use in treating certain diseases or in developing new cosmetic products. By exploring new applications, manufacturers can expand the market for resveratrol extract and bring more value - added products to the market.

5. Reputation in the Market

A manufacturer's reputation in the market is built over time through consistent product quality and good customer service.

5.1 Consistent Product Quality

Manufacturers that consistently produce high - quality resveratrol extract earn a good reputation. Customers in the supplement, pharmaceutical, and cosmetic industries rely on consistent quality to ensure the effectiveness and safety of their products. For example, a manufacturer that has a reputation for producing pure and potent resveratrol extract will be more likely to attract customers and build long - term relationships.

5.2 Good Customer Service

Good customer service is also an important part of a manufacturer's reputation. This includes aspects such as timely delivery, responsiveness to customer inquiries, and providing technical support. A manufacturer that can provide excellent customer service will be more likely to retain customers and gain new ones through positive word - of - mouth.

6. The Eight Top Resveratrol Extract Manufacturers

Now that we have discussed the important factors to consider when choosing a resveratrol extract manufacturer, let's take a look at eight of the top manufacturers in the industry.

6.1 Manufacturer A

Manufacturer A is known for its strict quality control procedures. They source their raw materials from some of the best grape - growing regions in the world. Their extraction and purification processes are state - of - the - art, using advanced technologies to ensure a high - purity resveratrol extract. In terms of production capacity, they have a large - scale facility that can meet the demands of the global market. Their R & D department is constantly working on improving extraction methods and exploring new applications for resveratrol. With a long - standing reputation in the market, they are a reliable choice for high - quality resveratrol extract.

6.2 Manufacturer B

Manufacturer B places a strong emphasis on quality control. They have a rigorous system in place for sourcing raw materials, ensuring that only the highest - quality grapes are used. Their extraction process is highly efficient, resulting in a high - yield of resveratrol extract. In addition, they have a significant production capacity, which allows them to offer competitive pricing. Their R & D efforts are focused on enhancing the purity of the extract and exploring its potential in the pharmaceutical industry. They have built a good reputation through consistent product quality and excellent customer service.

6.3 Manufacturer C

Manufacturer C is recognized for its innovative approach to resveratrol extraction. They use a unique combination of extraction techniques to produce a high - quality extract with a high concentration of resveratrol. Their quality control measures are comprehensive, covering every aspect of the production process from raw material sourcing to final product testing. They have a moderate - sized production facility but are known for their flexibility in meeting different customer requirements. Their R & D team is actively researching new applications of resveratrol in the cosmetic field, and they have a growing reputation in the market for their high - quality products.

6.4 Manufacturer D

Manufacturer D has a long history in the resveratrol extract manufacturing industry. They are renowned for their strict adherence to international quality standards. Their raw material sourcing is based on a network of trusted suppliers, ensuring a consistent supply of high - quality grapes. Their extraction and purification techniques are well - established, but they also invest in R & D to keep up with the latest trends. They have a large production capacity, which enables them to supply resveratrol extract to a wide range of customers around the world. Their reputation in the market is based on their reliability and the quality of their products.

6.5 Manufacturer E

Manufacturer E is a relatively new player in the resveratrol extract market, but they have quickly made a name for themselves. Their focus on quality control is evident in their choice of raw materials and extraction processes. They use advanced extraction technologies to produce a pure and potent resveratrol extract. Although their production capacity is currently smaller compared to some of the larger manufacturers, they are expanding rapidly. Their R & D capabilities are centered around exploring new applications of resveratrol in the supplement industry, and they have received positive feedback from customers for their high - quality products and good customer service.

6.6 Manufacturer F

Manufacturer F is known for its high - level quality control and production efficiency. They source their raw materials from sustainable and reliable sources. Their extraction process is optimized to produce a high - quality resveratrol extract with minimal waste. They have a large - scale production capacity that allows them to meet the demands of both domestic and international markets. Their R & D efforts are aimed at improving the extraction methods and enhancing the purity of the extract. They have a solid reputation in the market for their consistent product quality and on - time delivery.

6.7 Manufacturer G

Manufacturer G stands out for its comprehensive quality control system. They ensure that every batch of resveratrol extract meets strict quality standards. Their raw material sourcing is carefully managed to obtain the best - quality grapes. Their extraction and purification techniques are advanced, resulting in a high - purity extract. They have a moderate production capacity but are known for their ability to customize products according to customer needs. Their R & D department is exploring new applications of resveratrol in the medical field, and they have a good reputation for their reliable products and customer - focused service.

6.8 Manufacturer H

Manufacturer H is a leading manufacturer in the resveratrol extract industry. Their quality control processes are second to none, starting from the sourcing of raw materials all the way to the final packaging. They use a combination of traditional and modern extraction techniques to produce a high - quality extract. They have a large production capacity and are able to supply resveratrol extract to major markets around the world. Their R & D initiatives are focused on enhancing the purity and efficacy of the extract, as well as exploring new applications in various industries. With a long - established and excellent reputation, they are a top choice for many customers.

7. Conclusion

In conclusion, when choosing a white resveratrol extract manufacturer, it is important to consider factors such as quality control, production capacity, research and development capabilities, and market reputation. The eight manufacturers discussed in this article - Manufacturer A, Manufacturer B, Manufacturer C, Manufacturer D, Manufacturer E, Manufacturer F, Manufacturer G, and Manufacturer H - are all top choices in the industry. Each of them has its own strengths in terms of quality control, production, R & D, and reputation, making them reliable sources for high - quality white resveratrol extract. Whether you are in the supplement, pharmaceutical, or cosmetic industry, choosing one of these manufacturers can help ensure that you get a high - quality product that meets your needs.

FAQ:

Question 1: What are the key factors to consider when choosing a white resveratrol extract manufacturer?

When choosing a white resveratrol extract manufacturer, several key factors should be considered. Firstly, quality control is crucial. This includes sourcing high - quality raw materials and using advanced extraction and purification techniques to ensure the product meets international standards and is free from contaminants. Secondly, production capacity matters. A manufacturer with large - scale production capabilities can meet the global market demand and may offer more competitive pricing. Research and development is also important. Leading manufacturers invest in R & D to improve extraction methods, enhance purity, and explore new applications. Finally, reputation built on consistent product quality and good customer service is a significant factor.

Question 2: How can a manufacturer ensure the quality of white resveratrol extract?

A manufacturer can ensure the quality of white resveratrol extract through strict quality assurance procedures. This starts with sourcing high - quality raw materials. Then, they should implement advanced extraction and purification techniques. Regular testing at various stages of production is also necessary to make sure the product meets international standards and is free from contaminants such as heavy metals, pesticides, and other impurities.

Question 3: Why is production capacity significant for white resveratrol extract manufacturers?

Production capacity is significant for white resveratrol extract manufacturers because it can meet the growing demands of the global market. With large - scale production capabilities, a manufacturer can ensure a stable supply of the extract. This is important for industries such as the supplement, pharmaceutical, and cosmetic industries that rely on a consistent supply. Additionally, larger production volumes often lead to more competitive pricing, which can be an advantage in the market.

Question 4: What role does research and development play in white resveratrol extract manufacturing?

Research and development plays a crucial role in white resveratrol extract manufacturing. Manufacturers that invest in R & D can improve extraction methods, which may lead to higher yields and better quality of the extract. They can also enhance the purity of the extract, making it more suitable for various applications. Moreover, R & D allows manufacturers to explore new applications of white resveratrol, such as in new pharmaceutical formulations or cosmetic products, bringing more value - added products to the market.

Question 5: How do the top white resveratrol extract manufacturers build their reputation?

The top white resveratrol extract manufacturers build their reputation through consistent product quality and good customer service. By ensuring that their products always meet high - quality standards and are free from contaminants, they gain the trust of customers. Additionally, providing excellent customer service, such as prompt responses to inquiries and efficient order processing, also contributes to their positive reputation in the market.

Related literature

- Title: The Quality Assurance of Resveratrol Extract in the Supplement Industry"

- Title: "Production Capacity and Market Demand of Resveratrol Extract"

- Title: "Research and Development Trends in White Resveratrol Extraction"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Nutmeg Extract

2024-12-11

-

Phellodendron Extract

2024-12-11

-

Mango flavored powder

2024-12-11

-

Camu Camu Extract

2024-12-11

-

Boswellia Serrata Extract

2024-12-11

-

Red Wine Extract

2024-12-11

-

Curcuma Longa Extract

2024-12-11

-

Genistein

2024-12-11

-

Moringa powder

2024-12-11

-

Cat Claw Extract

2024-12-11