- 0086-571-85302990

- sales@greenskybio.com

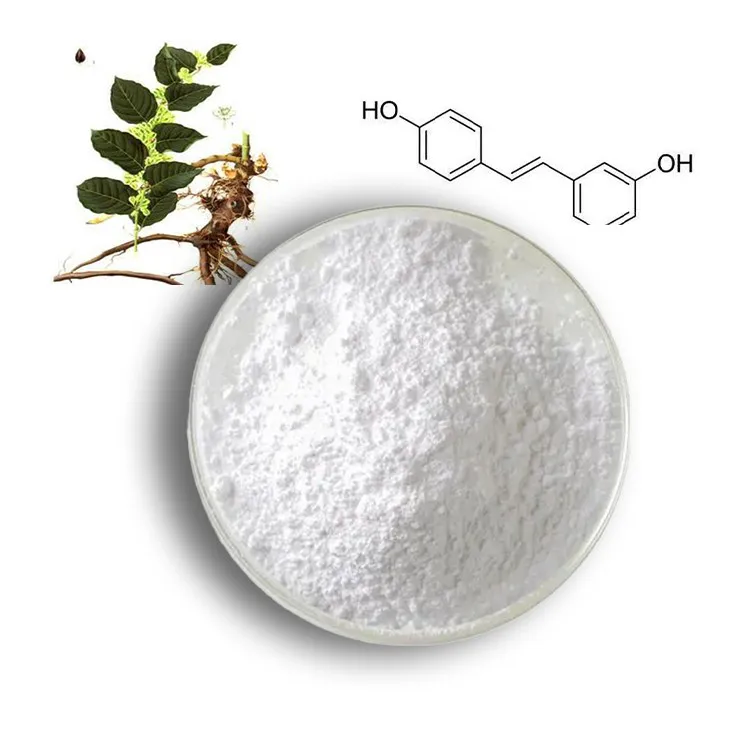

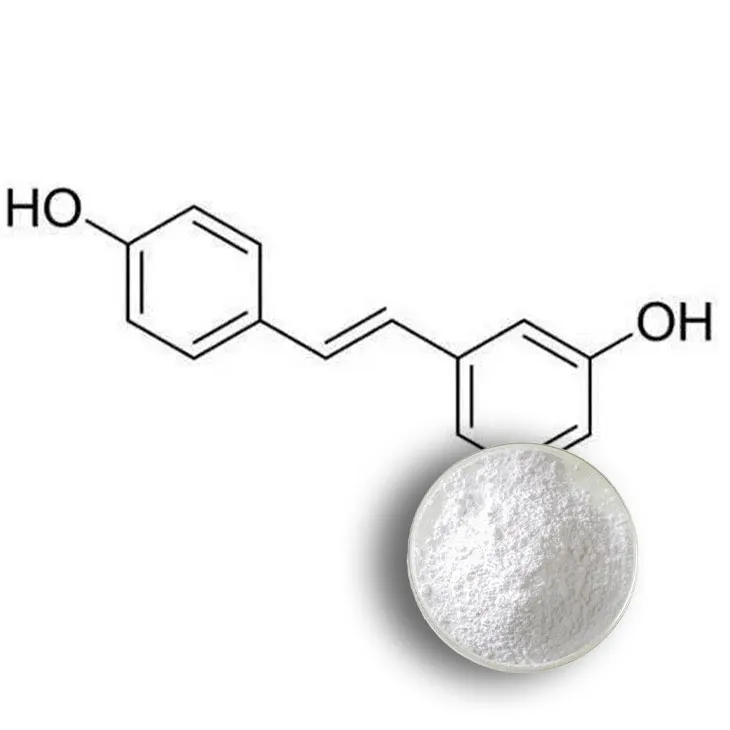

A Complete Guide to the Grinding Process of Resveratrol Extract: Step - by - Step Key Points

2024-12-20

1. Introduction

Resveratrol, especially the white Resveratrol extract, has gained significant attention in various industries such as pharmaceuticals, cosmetics, and food supplements due to its numerous health - promoting properties. The grinding process of this extract is a critical step that can influence its quality, bioavailability, and subsequent applications. This guide aims to provide a comprehensive understanding of the step - by - step key points in the grinding process of Resveratrol extract.

2. Pre - Grinding Considerations

2.1 Raw Material Quality

The quality of the raw resveratrol material is fundamental. High - quality raw materials should be sourced, preferably from reliable suppliers. The purity, origin, and extraction method of the resveratrol can impact the final product. For example, Resveratrol extracted from grapes using advanced extraction techniques is likely to have better quality compared to those from less - reliable sources. Before grinding, it is essential to perform quality checks such as purity analysis and identification of potential contaminants.

2.2 Equipment Selection

- Grinding mills: There are various types of grinding mills available, such as ball mills, hammer mills, and jet mills. The choice depends on factors like the required particle size, throughput, and the nature of the resveratrol extract. For example, ball mills are suitable for fine grinding and can produce particles in the micron range, which may be ideal for certain pharmaceutical applications.

- Material of construction: The equipment should be made of suitable materials that are non - reactive with resveratrol. Stainless steel is a common choice as it is inert and can withstand the grinding process without contaminating the extract.

3. The Grinding Process Steps

3.1 Preparation of the Grinding Chamber

- Before starting the grinding process, the grinding chamber should be thoroughly cleaned. Any residual particles from previous grinding operations can contaminate the resveratrol extract. Use appropriate cleaning agents and ensure that the chamber is completely dry before adding the resveratrol.

- Check the integrity of the grinding chamber components. Any worn - out parts, such as bearings or seals, should be replaced to ensure proper functioning during grinding.

3.2 Loading the Resveratrol

- Carefully measure the amount of resveratrol to be ground. This is crucial for maintaining consistency in the final product. Use accurate weighing devices to ensure the correct quantity is loaded into the grinding chamber.

- Ensure that the resveratrol is evenly distributed within the grinding chamber. Uneven distribution can lead to inconsistent grinding results, with some particles being over - ground while others remain unground.

3.3 Grinding Parameters

- Rotation speed: Set the appropriate rotation speed of the grinding mill. A higher rotation speed generally results in a faster grinding process but may also generate more heat. For resveratrol, excessive heat can cause degradation. Therefore, an optimal rotation speed should be determined based on the equipment and the nature of the resveratrol, typically in the range of [X] to [Y] revolutions per minute.

- Grinding time: The grinding time is another critical parameter. It should be long enough to achieve the desired particle size but not so long as to cause over - grinding or heat - induced degradation. Conduct preliminary tests to determine the optimal grinding time for the specific resveratrol extract. For example, in some cases, a grinding time of [Z] minutes may be sufficient to reach the target particle size.

4. Safety Measures during Grinding

4.1 Operator Protection

- Operators should wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and lab coats. Safety glasses protect the eyes from any flying particles during the grinding process, while gloves prevent skin contact with the resveratrol, which may cause irritation in some cases.

- Proper training should be provided to operators regarding the safe operation of the grinding equipment. They should be aware of emergency stop procedures and how to handle any potential malfunctions.

4.2 Equipment Safety

- Regular maintenance of the grinding equipment is essential for safety. This includes checking for loose parts, proper lubrication of moving components, and ensuring that safety guards are in place. For example, the safety guards around the grinding chamber should be intact to prevent accidental access during operation.

- Install appropriate ventilation systems to remove any dust or fumes generated during grinding. Resveratrol dust can be a potential inhalation hazard, and proper ventilation helps to maintain a safe working environment.

5. Quality Control during Grinding

5.1 Particle Size Analysis

- During the grinding process, periodic particle size analysis should be carried out. This can be done using techniques such as laser diffraction or sieve analysis. Laser diffraction is a more advanced method that can provide detailed information about the particle size distribution. By monitoring the particle size, adjustments can be made to the grinding parameters if the desired size is not being achieved.

- Set specific particle size targets based on the intended application of the resveratrol extract. For example, in a pharmaceutical formulation, a very fine particle size may be required for better bioavailability, while in a food supplement, a slightly larger but still well - dispersed particle size may be acceptable.

5.2 Purity and Contamination Checks

- Regularly check for any signs of contamination during grinding. This can include the presence of foreign particles, which may have entered the grinding chamber through improper handling or from the environment. Use microscopy or other analytical techniques to detect and identify potential contaminants.

- Monitor the purity of the resveratrol throughout the grinding process. Any decrease in purity may indicate chemical reactions or interactions within the grinding chamber, such as oxidation or reaction with the grinding media. If a significant decrease in purity is detected, the grinding process should be halted and investigated.

6. Post - Grinding Handling

6.1 Collection and Packaging

- After the grinding process is complete, carefully collect the ground resveratrol extract. Use clean and appropriate collection containers to avoid any re - contamination. The containers should be made of materials that are compatible with resveratrol, such as high - density polyethylene or glass.

- Properly package the ground resveratrol for storage and transportation. The packaging should provide protection from environmental factors such as moisture, light, and air. For example, using vacuum - sealed packaging can help prevent oxidation and maintain the quality of the resveratrol.

6.2 Storage Conditions

- Store the ground resveratrol in a cool, dry place. High temperatures and humidity can accelerate the degradation of resveratrol. A temperature - controlled storage area with a relative humidity of less than [X]% is ideal.

- Protect the stored resveratrol from light exposure. Light can cause photochemical reactions in resveratrol, leading to a decrease in its activity. Use opaque containers or store the product in a dark area.

7. Conclusion

The grinding process of resveratrol extract is a complex but crucial operation. By following the step - by - step key points outlined in this guide, industries and researchers can ensure the production of high - quality resveratrol extracts. From pre - grinding considerations such as raw material quality and equipment selection to in - process safety measures, quality control, and post - grinding handling, each aspect plays an important role in achieving a final product that meets the desired specifications for various applications.

FAQ:

Q1: What are the key factors to consider for the optimal grinding conditions of resveratrol extract?

The key factors include the type of grinding equipment, the grinding time, and the temperature. Different grinding equipment may have different effects on the particle size and quality of the resveratrol extract. Appropriate grinding time ensures that the extract is ground to the desired fineness without over - grinding, which may cause degradation. The temperature should be controlled as high temperature may also lead to the degradation of resveratrol.

Q2: How can safety be ensured during the grinding process of resveratrol extract?

First, operators should wear appropriate personal protective equipment, such as gloves and goggles. Second, the grinding equipment should be regularly inspected and maintained to ensure its proper operation and prevent any mechanical failures or leaks. Also, proper ventilation in the grinding area is necessary to avoid the inhalation of any dust or fumes generated during the process.

Q3: What are the main quality control methods during the grinding process of resveratrol extract?

One important method is to monitor the particle size distribution regularly. This can be done using particle size analyzers. Another is to test the chemical composition of the ground resveratrol extract to ensure that no significant chemical changes, such as degradation, have occurred. Spectroscopic techniques like HPLC can be used for this purpose.

Q4: Why is the grinding process important for the application of resveratrol extract?

The grinding process can affect the solubility, bioavailability, and reactivity of resveratrol extract. Finely ground resveratrol may have better solubility, which is crucial for its use in formulations such as pharmaceuticals or cosmetics. It can also influence the rate of release and absorption in biological systems, thus affecting its bioavailability. Additionally, the grinding process may impact its reactivity in chemical or biological reactions relevant to its applications.

Q5: Are there any specific types of grinding equipment recommended for resveratrol extract?

Ball mills are often a good choice as they can provide relatively uniform grinding. However, depending on the scale of production and specific requirements, other types such as mortar and pestle for small - scale laboratory use, or more advanced industrial - scale mills like jet mills may also be considered. Each type has its own advantages and limitations in terms of grinding efficiency, particle size control, and cost.

Related literature

- Optimization of the Grinding Process for Herbal Extracts: A Case Study of Resveratrol"

- "The Impact of Grinding on the Quality and Bioactivity of Resveratrol - Rich Extracts"

- "Quality Control in the Grinding of Phytochemical Extracts: Focus on Resveratrol"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Medicinal Marshmallow Extract

2024-12-20

-

Acai Berry Extract

2024-12-20

-

Gynostemma pentaphyllum extract

2024-12-20

-

White Peony Extract

2024-12-20

-

Bilberry Extract

2024-12-20

-

Marigold Extract

2024-12-20

-

Shikone Extract

2024-12-20

-

Jujube Extract

2024-12-20

-

Garcinia Cambogia Extract

2024-12-20

-

Hedyotis Diffusa Extract

2024-12-20