- 0086-571-85302990

- sales@greenskybio.com

A Guide to Understanding the Powder Proportion of Eucommia ulmoides Extract.

2024-12-31

1. Introduction

Eucommia ulmoides, a well - known traditional Chinese medicinal plant, has been widely studied and utilized in various fields. The extract of Eucommia ulmoides contains a rich variety of bioactive components. Among them, understanding the powder proportion of the extract is crucial for its production, quality control, and application. This article aims to provide a comprehensive guide to this important aspect.

2. Production Requirements and Powder Proportion

2.1 Raw Material Selection

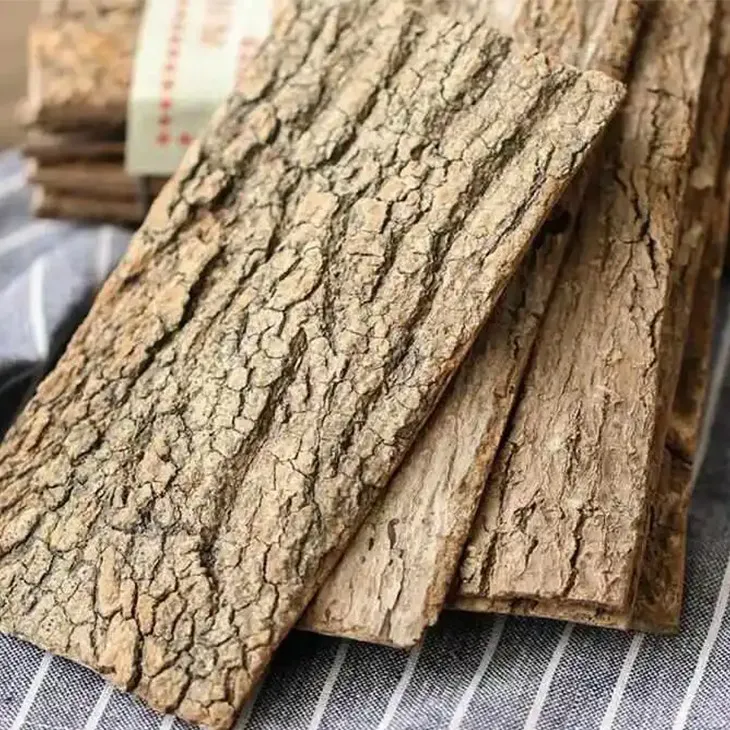

The quality of the raw materials of Eucommia ulmoides directly affects the powder proportion in the extract. High - quality Eucommia ulmoides should be selected, which is usually determined by factors such as the growth environment, growth time, and harvesting time. For example, Eucommia ulmoides grown in suitable soil and climate conditions may have a higher content of active ingredients. When harvesting, it is necessary to ensure that the plant has reached an appropriate maturity level. If the raw materials are of poor quality, it may lead to an unstable powder proportion in the subsequent extraction process.

2.2 Extraction Methods

Different extraction methods can also influence the powder proportion. There are several common extraction methods for Eucommia Ulmoides Extract, such as solvent extraction and supercritical fluid extraction.

Solvent extraction: This method uses solvents like ethanol or water to extract the active ingredients from Eucommia ulmoides. The choice of solvent, extraction time, and extraction temperature all play important roles in determining the powder proportion. For instance, a higher extraction temperature may increase the extraction rate in a short time, but it may also cause some components to decompose, thus affecting the final powder proportion.

Supercritical fluid extraction: Using supercritical carbon dioxide as the extraction medium, this method has the advantages of high efficiency and environmental protection. However, the pressure, temperature, and flow rate of the supercritical fluid need to be precisely controlled. Improper control may lead to differences in the extraction of different components, thereby changing the powder proportion.

3. Quality Control and Powder Proportion

3.1 Standardization of Powder Proportion

In the production of Eucommia Ulmoides Extract, establishing a standardized powder proportion is essential for ensuring product quality. Manufacturers need to refer to relevant national and international standards. For example, in some pharmacopoeias, there are clear regulations on the content range of certain active ingredients in Eucommia Ulmoides Extract, which indirectly affects the powder proportion. Through strict quality control measures, such as regular sampling and testing during the production process, any deviation in the powder proportion can be detected and corrected in a timely manner.

3.2 Impurity Control

Impurities in the extract can also impact the powder proportion. These impurities may come from the raw materials themselves, such as soil residues, or may be generated during the extraction process, like solvent residues. Effective impurity removal methods are necessary. For example, filtration, centrifugation, and purification techniques can be used to reduce the content of impurities. If the impurity content is too high, it will not only affect the accuracy of the powder proportion but also may have potential safety risks for the end - use of the extract.

4. The Impact of Different Powder Proportions on Efficacy

4.1 Bioactive Components and Efficacy

Eucommia ulmoides extract contains various bioactive components, such as flavonoids, lignans, and polysaccharides. The powder proportion directly affects the content of these components in the final product, and thus their efficacy.

Flavonoids: They have antioxidant, anti - inflammatory, and cardiovascular - protective effects. If the powder proportion is adjusted in a way that increases the content of flavonoids in the extract, the antioxidant and anti - inflammatory capabilities of the product may be enhanced. For example, in some studies, it has been found that when the powder proportion is optimized to a certain level, the antioxidant activity of Eucommia ulmoides extract can be significantly improved.

Lignans: Lignans in Eucommia ulmoides are known for their estrogen - like effects and potential anti - cancer properties. A proper powder proportion can ensure an appropriate amount of lignans in the extract, which is crucial for realizing these biological functions. If the powder proportion is too low, the content of lignans may be insufficient, and the expected biological effects may not be achieved.

Polysaccharides: Polysaccharides have immunomodulatory and hypoglycemic effects. Changes in the powder proportion can influence the content of polysaccharides in the extract. When the powder proportion is well - controlled, the polysaccharides can play their roles more effectively, such as enhancing the immune function of the body or helping to regulate blood sugar levels.

4.2 Dosage - Response Relationship

The powder proportion also affects the dosage - response relationship of the Eucommia ulmoides extract. Different powder proportions mean different concentrations of active ingredients. In clinical or experimental applications, it is necessary to find the optimal powder proportion to achieve the best therapeutic or preventive effects with the least amount of extract.

For example, in some animal experiments, when the powder proportion of Eucommia ulmoides extract is set at a certain value, a certain dose of the extract can effectively reduce blood pressure in hypertensive animals. However, if the powder proportion is changed, the same dose may not produce the same effect, or may even cause adverse reactions. Therefore, understanding the relationship between powder proportion and dosage - response is of great significance for the rational use of Eucommia ulmoides extract.

5. Conclusion

In conclusion, the powder proportion of Eucommia ulmoides extract is a complex but crucial factor. It is related to production requirements, quality control, and the efficacy of the extract. By comprehensively considering factors such as raw material selection, extraction methods, quality control, and the impact on efficacy, manufacturers and researchers can better optimize the powder proportion, ensuring the high - quality production and effective application of Eucommia ulmoides extract. This will also contribute to the further development and utilization of Eucommia ulmoides in the fields of medicine, health products, and cosmetics.

FAQ:

What factors influence the powder proportion of Eucommia ulmoides extract?

The powder proportion of Eucommia ulmoides extract can be influenced by various factors. Firstly, the raw material quality plays a role. High - quality Eucommia ulmoides bark may result in different extraction yields and thus affect the proportion. Secondly, the extraction method matters. Different extraction techniques, such as solvent extraction or supercritical fluid extraction, can lead to different amounts of active compounds being extracted, which in turn impacts the powder proportion. Also, the purpose of the extract, whether for medicinal use or in dietary supplements, may determine the desired proportion to achieve the optimal efficacy.

How is the powder proportion of Eucommia ulmoides extract related to quality control?

In quality control, the powder proportion of Eucommia ulmoides extract is a crucial factor. If the proportion is not within the specified range, it may indicate problems in the production process. For example, an incorrect proportion could mean improper extraction conditions or inaccurate measurement of raw materials. Maintaining the right powder proportion ensures that the extract contains the appropriate amount of active ingredients, which is essential for guaranteeing its quality, consistency, and safety. Quality control measures such as standard operating procedures, regular sampling, and analysis are used to monitor and adjust the powder proportion as needed.

Can different powder proportions of Eucommia ulmoides extract have different pharmacological effects?

Yes, different powder proportions of Eucommia ulmoides extract can have different pharmacological effects. A lower proportion may not provide sufficient active compounds to exert the desired therapeutic effects. For instance, if the proportion is too low, the anti - hypertensive or anti - inflammatory properties may not be fully realized. On the other hand, a very high proportion may lead to potential toxicity or unwanted side effects. The optimal powder proportion is designed to balance the effectiveness and safety, ensuring that the extract can achieve its intended pharmacological actions, such as promoting bone health, improving cardiovascular function, or enhancing immune response.

How is the powder proportion determined during the production of Eucommia ulmoides extract?

During the production of Eucommia ulmoides extract, the powder proportion is determined through a combination of methods. Initially, scientific research on the active ingredients in Eucommia ulmoides and their optimal concentrations for desired effects is considered. Then, based on the extraction method chosen, the amount of raw material used and the expected yield are calculated. Pilot - scale tests are often carried out to fine - tune the proportion. Additionally, industry standards and regulatory requirements may also play a role in dictating the acceptable range of the powder proportion. Analytical techniques such as high - performance liquid chromatography (HPLC) are used to measure the content of key active components and ensure that the powder proportion is within the desired limits.

What are the challenges in maintaining the correct powder proportion of Eucommia ulmoides extract?

There are several challenges in maintaining the correct powder proportion of Eucommia ulmoides extract. One challenge is the variability in raw material quality. Since Eucommia ulmoides bark may vary in its chemical composition depending on factors like the origin, growth conditions, and harvesting time, it can be difficult to ensure a consistent powder proportion. Another challenge is the complexity of the extraction process. Small changes in extraction parameters such as temperature, pressure, and solvent type can significantly affect the extraction yield and thus the powder proportion. Additionally, the lack of standardized methods across the industry can also pose a problem, as different producers may use different approaches to determine and control the powder proportion.

Related literature

- Study on the Active Components and Pharmacological Effects of Eucommia ulmoides Extract"

- "Optimization of Extraction Process for Eucommia ulmoides and Its Impact on the Powder Proportion"

- "Quality Control of Eucommia ulmoides Extract: Focus on Powder Proportion and Efficacy"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Mango flavored powder

2024-12-31

-

Lavender Extract

2024-12-31

-

Cranberry Extract

2024-12-31

-

Beta Carotene

2024-12-31

-

Elderberry Extract

2024-12-31

-

Resveratrol extract

2024-12-31

-

Almond Extract Powder

2024-12-31

-

Oyster Mushroom Extract Powder

2024-12-31

-

Licorice Root Extract Powder

2024-12-31

-

Bitter Melon Extract

2024-12-31