- 0086-571-85302990

- sales@greenskybio.com

Astaxanthin products: Which extraction technologies should your enterprise invest in?

2024-12-22

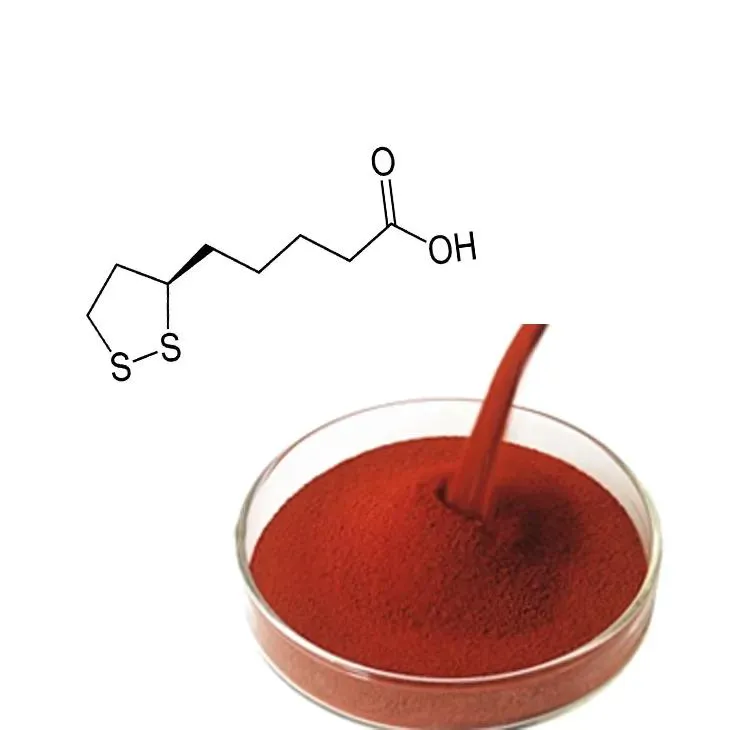

1. Introduction to Astaxanthin

Astaxanthin is a powerful antioxidant that has gained significant attention in various industries, including the food, cosmetic, and pharmaceutical sectors. It is responsible for the red coloration in many marine organisms such as salmon, shrimp, and krill. Due to its numerous health benefits, the demand for Astaxanthin - based products has been steadily increasing. However, the extraction of astaxanthin is a crucial step in its production process, and different extraction technologies can have a significant impact on the quality, cost, and environmental sustainability of the final product.

2. Common Extraction Technologies for Astaxanthin

2.1 Organic Solvent Extraction

Principle: Organic solvent extraction is one of the most traditional methods. It involves using organic solvents such as hexane, acetone, or ethanol to dissolve astaxanthin from the source material. The astaxanthin - rich solution is then separated from the solid residue, and the solvent is removed to obtain the astaxanthin extract.

Efficiency: This method can be relatively efficient in terms of extracting a significant amount of astaxanthin. However, the efficiency can vary depending on the nature of the source material and the choice of solvent.

Purity: The purity of the extracted astaxanthin may not be very high as there could be co - extraction of other lipids and compounds. Additional purification steps are often required to obtain a high - purity astaxanthin product.

Environmental Impact: The use of organic solvents poses environmental risks. Many organic solvents are volatile organic compounds (VOCs) that can contribute to air pollution. Moreover, proper disposal of the used solvents is necessary to avoid soil and water contamination.

2.2 Supercritical Fluid Extraction (SFE)

Principle: In supercritical fluid extraction, a supercritical fluid, usually carbon dioxide (CO₂), is used as the extracting agent. Supercritical CO₂ has properties between those of a gas and a liquid, allowing it to penetrate the source material and selectively extract astaxanthin. The extraction is carried out under specific pressure and temperature conditions.

Efficiency: SFE can be highly efficient in extracting astaxanthin. It can achieve a relatively high extraction yield, especially when the process parameters are optimized. It also has a shorter extraction time compared to some traditional methods.

Purity: The purity of the astaxanthin obtained by SFE can be relatively high as the supercritical fluid can selectively extract astaxanthin while leaving behind many impurities. This reduces the need for extensive purification steps.

Environmental Impact: Supercritical CO₂ is a relatively environmentally friendly extracting agent. It is non - toxic, non - flammable, and has a low environmental impact. After the extraction, the CO₂ can be easily recycled, reducing waste and environmental footprint.

2.3 Enzymatic Extraction

Principle: Enzymatic extraction utilizes specific enzymes to break down the cell walls of the source material, thereby releasing astaxanthin. Enzymes such as cellulases, proteases, and lipases can be used depending on the nature of the source material.

Efficiency: The efficiency of enzymatic extraction can be moderate. It may require a longer reaction time compared to some other methods, but it can be effective in extracting astaxanthin from complex biological matrices.

Purity: The purity of the extracted astaxanthin can be relatively high as the enzymatic process can be somewhat selective. However, there may still be some co - extraction of other substances that may need further purification.

Environmental Impact: Enzymatic extraction is generally considered to be more environmentally friendly compared to organic solvent extraction. Enzymes are biodegradable, and the process does not involve the use of harsh chemicals.

3. Factors to Consider for Enterprise Investment

3.1 Cost - Benefit Analysis

Initial Investment: When considering organic solvent extraction, the initial investment may be relatively low as the equipment required is relatively simple. However, the long - term costs associated with solvent purchase, handling, and disposal can be significant. For supercritical fluid extraction, the initial investment in equipment such as high - pressure vessels and pumps can be high, but the long - term savings in terms of reduced solvent costs and higher product quality may offset this. Enzymatic extraction may also require an investment in enzyme production or purchase, but the overall cost may be more favorable in terms of environmental compliance and product purity.

Operating Costs: Organic solvent extraction has relatively high operating costs due to the need for continuous solvent supply and waste disposal. Supercritical fluid extraction has lower operating costs in terms of solvent usage (since CO₂ can be recycled), but the energy requirements for maintaining the supercritical state can be a factor. Enzymatic extraction has relatively low operating costs as enzymes are used in small amounts and do not require complex disposal procedures.

3.2 Product Quality Requirements

If the enterprise aims to produce high - purity astaxanthin for pharmaceutical or high - end cosmetic applications, supercritical fluid extraction or enzymatic extraction may be more suitable. These methods can provide higher - purity products with fewer impurities compared to organic solvent extraction. However, if the product is for general food or feed applications, and cost is a major factor, organic solvent extraction may be considered, although additional purification steps may be necessary to meet quality standards.

3.3 Regulatory Compliance

Regulatory requirements vary depending on the industry and the target market. In the food and pharmaceutical industries, strict regulations govern the purity, safety, and origin of astaxanthin products. Supercritical fluid extraction and enzymatic extraction may be more likely to meet these regulatory requirements due to their cleaner extraction processes. Organic solvent extraction may face more challenges in terms of meeting regulatory limits for solvent residues in the final product.

3.4 Environmental Sustainability

Enterprises are increasingly under pressure to adopt environmentally sustainable production processes. Supercritical fluid extraction, with its use of recyclable CO₂, and enzymatic extraction, with its biodegradable enzymes, are more environmentally friendly options compared to organic solvent extraction. Choosing an environmentally sustainable extraction technology can also enhance the enterprise's brand image and market competitiveness.

4. Conclusion

When considering investment in astaxanthin extraction technologies, enterprises need to carefully evaluate various factors such as efficiency, purity, cost, regulatory compliance, and environmental impact. Each extraction technology has its own advantages and disadvantages, and the optimal choice will depend on the specific needs and goals of the enterprise. By making an informed decision, enterprises can not only produce high - quality astaxanthin products but also ensure long - term viability and competitiveness in the astaxanthin industry.

FAQ:

Q1: What are the common extraction technologies for astaxanthin?

Some common extraction technologies for astaxanthin include organic solvent extraction, supercritical fluid extraction, and enzymatic extraction. Organic solvent extraction is a traditional method that uses solvents like hexane or ethanol. Supercritical fluid extraction often uses carbon dioxide in a supercritical state, which has advantages in terms of purity and environmental friendliness. Enzymatic extraction utilizes specific enzymes to break down cell walls and release astaxanthin.

Q2: Which extraction technology is the most efficient for astaxanthin?

The efficiency of extraction technology depends on various factors. Supercritical fluid extraction can be highly efficient as it can quickly and selectively extract astaxanthin. However, the efficiency also depends on the raw material source and the scale of production. For small - scale production with certain types of raw materials, enzymatic extraction might show good efficiency in terms of yield per unit of raw material. Organic solvent extraction can also be efficient in terms of overall extraction amount but may have drawbacks in terms of post - extraction processing.

Q3: How does extraction technology affect the purity of astaxanthin?

Supercritical fluid extraction generally results in a high - purity astaxanthin product. Since it can precisely control the extraction conditions and selectively extract astaxanthin, fewer impurities are co - extracted. Enzymatic extraction can also produce relatively pure astaxanthin if the enzymatic reaction is well - controlled. In contrast, organic solvent extraction may co - extract other substances from the raw material, which might require additional purification steps to achieve high purity.

Q4: What is the environmental impact of different astaxanthin extraction technologies?

Organic solvent extraction often uses volatile and potentially harmful solvents, which can have a negative environmental impact if not properly managed. These solvents may be released into the environment during the extraction and solvent recovery processes. Supercritical fluid extraction, especially when using carbon dioxide, is considered more environmentally friendly as carbon dioxide is non - toxic and can be easily recycled. Enzymatic extraction also has relatively low environmental impact as the enzymes used are generally biodegradable and the process generates less waste compared to organic solvent extraction.

Q5: How can an enterprise choose the right astaxanthin extraction technology?

An enterprise should consider several factors when choosing an astaxanthin extraction technology. First, it needs to look at the cost - effectiveness, including the cost of equipment, raw materials, and operation. Second, the quality requirements of the astaxanthin product, such as purity and stability, are crucial. Third, the scale of production also matters. For large - scale production, supercritical fluid extraction or a combination of methods might be more suitable. Additionally, environmental regulations and the availability of resources in the enterprise's location should also be taken into account.

Related literature

- Advances in Astaxanthin Extraction Technologies"

- "Comparative Study of Astaxanthin Extraction Methods: Efficiency, Purity and Environmental Impact"

- "The Future of Astaxanthin Production: Selection of Optimal Extraction Technologies"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Sophora Japonica Flower Extract

2024-12-22

-

Almond Extract Powder

2024-12-22

-

Saponin Extract

2024-12-22

-

Chasteberry Extract

2024-12-22

-

Hericium erinaceus extract powder

2024-12-22

-

Konjac Powder

2024-12-22

-

Saffron Extract Powder

2024-12-22

-

Citrus bioflavonoids

2024-12-22

-

Berberis aristata Extract

2024-12-22

-

Motherwort Extract

2024-12-22