- 0086-571-85302990

- sales@greenskybio.com

Complete Guide to Kidney Bean Extract Grinding Process: Step - by - Step Key Points

2025-01-02

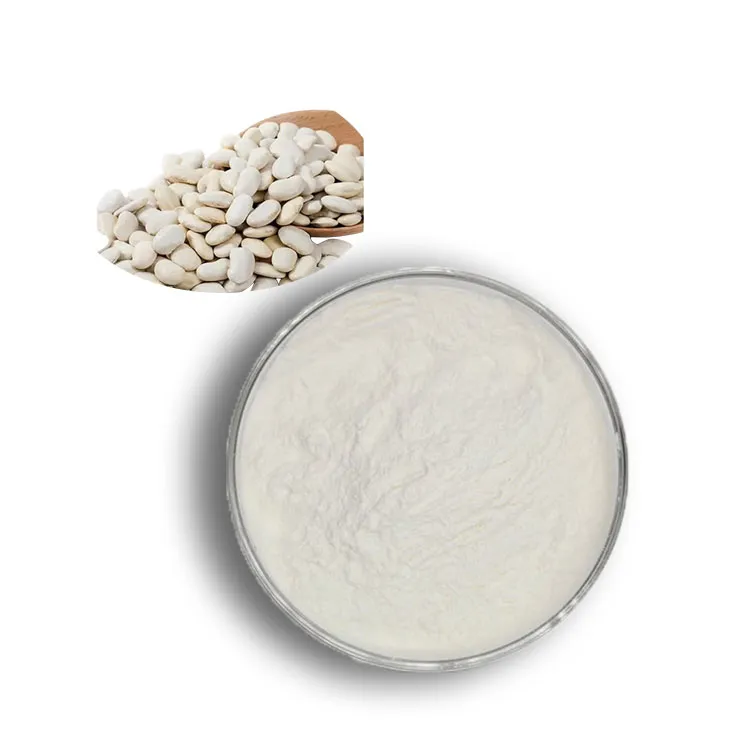

1. Introduction to Kidney Bean Extract

Kidney beans are a rich source of various nutrients and bioactive compounds. Kidney Bean Extract has gained significant attention in recent years due to its potential health benefits. It contains proteins, fibers, antioxidants, and other substances that may contribute to better health. The extraction and grinding process of Kidney Bean Extract play a crucial role in making these beneficial components accessible for various applications, such as in the food, pharmaceutical, and nutraceutical industries.

2. Pre - Grinding Preparation

2.1 Selection of Kidney Beans

The first step in the grinding process of kidney bean extract is the careful selection of kidney beans. High - quality beans should be chosen. Look for beans that are:

- Uniform in size and shape.

- Free from any visible signs of damage, such as cracks or mold.

- Preferably sourced from reliable suppliers to ensure consistency in quality.

2.2 Cleaning the Kidney Beans

Once the beans are selected, they need to be thoroughly cleaned. This is an important step as any dirt, debris, or foreign particles can affect the quality of the extract.

- Wash the kidney beans in clean water multiple times until the water runs clear.

- Remove any floating or damaged beans during the washing process.

2.3 Soaking the Kidney Beans

Soaking the kidney beans is a necessary pre - grinding step. It helps in softening the beans, which in turn makes the grinding process easier.

- Place the cleaned kidney beans in a container and add enough water to cover them completely.

- Soak the beans for a specific period, usually between 6 - 12 hours. However, the soaking time may vary depending on factors such as the type of kidney bean and the ambient temperature.

- After soaking, drain the water completely. This drained water may contain some water - soluble components, but for the purpose of obtaining a concentrated extract, it is usually discarded.

3. Grinding Equipment Selection

The choice of grinding equipment is vital for the successful extraction of kidney bean extract. There are different types of grinders available, each with its own advantages and limitations.

3.1 Manual Grinders

Manual grinders, such as mortar and pestle, are a traditional option. They are suitable for small - scale operations or for those who prefer a more hands - on approach.

- Advantages:

- They provide better control over the grinding process, allowing for a more precise texture.

- They are relatively inexpensive and do not require electricity.

- Limitations:

- They are time - consuming, especially for larger quantities of kidney beans.

- The grinding may not be as uniform as with mechanical grinders.

3.2 Mechanical Grinders

Mechanical grinders are more commonly used in industrial and large - scale operations. There are different types of mechanical grinders, such as:

- Blade grinders:

- Advantages:

- They are fast and can grind a large amount of kidney beans in a short time.

- They are relatively easy to operate and clean.

- Limitations:

- The heat generated during grinding may affect the quality of the extract, especially if the grinding process is prolonged.

- They may not be able to achieve a very fine grind compared to other mechanical grinders.

- Advantages:

- Stone grinders:

- Advantages:

- They can produce a very fine and uniform grind, which is beneficial for obtaining a high - quality kidney bean extract.

- They generate less heat during grinding, reducing the risk of heat - related damage to the extract components.

- Limitations:

- They are usually more expensive than blade grinders.

- They may require more maintenance due to the nature of the stone grinding mechanism.

- Advantages:

4. The Grinding Process

4.1 Grinding in Manual Grinders

If using a mortar and pestle for grinding kidney bean extract:

- Place the soaked and drained kidney beans in the mortar.

- Using the pestle, start applying gentle pressure and make circular motions to break down the beans. Gradually increase the pressure as the beans start to break apart.

- Continue the grinding process until the desired texture is achieved. This may take some time, and it is important to check the consistency regularly.

4.2 Grinding in Blade Grinders

For blade grinders:

- Place the soaked and drained kidney beans in the grinder's container. Make sure not to overfill the container to ensure proper grinding.

- Secure the lid of the grinder properly and turn on the grinder. Most blade grinders have different speed settings. Start with a lower speed and gradually increase it if needed.

- Allow the grinder to run for a short period, usually between 30 seconds to 2 minutes, depending on the quantity of beans and the desired fineness of the grind. Stop the grinder and check the consistency of the ground kidney beans. If further grinding is required, repeat the process.

4.3 Grinding in Stone Grinders

When using stone grinders:

- Feed the soaked and drained kidney beans into the hopper or inlet of the stone grinder at a slow and steady rate.

- The stone grinder will start grinding the beans as they pass through the grinding mechanism. Adjust the settings of the stone grinder, if possible, to control the fineness of the grind.

- Monitor the output of the stone grinder continuously to ensure that the ground kidney beans meet the desired quality standards.

5. Post - Grinding Processing

5.1 Sieving the Ground Kidney Beans

After grinding, it is often necessary to sieve the ground kidney beans to separate the finer particles from the coarser ones.

- Use a sieve with an appropriate mesh size. For a relatively fine kidney bean extract, a sieve with a smaller mesh size may be used.

- Pour the ground kidney beans into the sieve and gently shake or tap the sieve to allow the finer particles to pass through while retaining the coarser ones.

- The coarser particles can be re - ground if necessary to obtain a more complete extraction.

5.2 Extracting the Soluble Components

The ground kidney beans still contain soluble components that need to be extracted.

- Add an appropriate solvent, such as water or a specific organic solvent depending on the nature of the desired extract, to the sieved ground kidney beans.

- Stir the mixture thoroughly to ensure that the soluble components are dissolved in the solvent. This can be done using a mechanical stirrer or by hand.

- Allow the mixture to stand for a certain period, usually between 30 minutes to 2 hours, to ensure complete extraction.

5.3 Filtration of the Extract

After the extraction process, the extract needs to be filtered to remove any remaining solid particles.

- Use a filter paper or a filtration device with an appropriate pore size. Place the filter in a funnel and pour the extract - solvent mixture into the funnel.

- The filtrate, which is the kidney bean extract, will pass through the filter, while the solid particles will be retained on the filter.

- Collect the filtrate in a clean container for further processing or storage.

6. Quality Control and Storage

6.1 Quality Control

Quality control is essential throughout the kidney bean extract grinding process.

- Regularly check the quality of the kidney beans at each stage, from selection to post - grinding. This includes checking for physical characteristics such as color, texture, and absence of contaminants.

- Monitor the grinding process parameters, such as the grinding time, speed, and temperature (especially for mechanical grinders). Ensure that these parameters are within the acceptable range to maintain the quality of the extract.

- Test the final extract for its chemical composition, including the presence and concentration of desired bioactive compounds. This can be done using various analytical techniques such as HPLC (High - Performance Liquid Chromatography) or spectrophotometry.

6.2 Storage

Proper storage of the kidney bean extract is crucial to maintain its quality over time.

- Store the extract in a cool, dry place, away from direct sunlight. Exposure to heat, light, and moisture can cause degradation of the extract components.

- Use appropriate containers, such as amber - colored glass bottles or sealed plastic containers, to protect the extract from environmental factors. Amber - colored bottles are preferred as they can block out UV light, which can be harmful to the extract.

- Label the containers clearly with information such as the date of extraction, batch number, and contents. This helps in easy identification and traceability.

7. Conclusion

The grinding process of kidney bean extract is a multi - step and complex procedure that requires careful attention to detail. From the pre - grinding preparation steps, such as bean selection, cleaning, and soaking, to the selection of appropriate grinding equipment, and finally to the post - grinding processing and quality control, each step plays a crucial role in obtaining a high - quality kidney bean extract. By following the step - by - step key points outlined in this guide, it is possible to produce kidney bean extract that meets the desired quality standards for various applications in the food, pharmaceutical, and nutraceutical industries.

FAQ:

What are the main steps in the kidney bean extract grinding process?

The main steps in the kidney bean extract grinding process typically include raw material preparation, such as cleaning and drying the kidney beans. Then, the beans are usually crushed into smaller pieces. After that, a fine - grinding step is carried out to achieve the desired particle size for the extract. There may also be steps for filtration and purification during or after the grinding process to remove impurities.

What equipment is commonly used in the kidney bean extract grinding process?

Commonly used equipment in the kidney bean extract grinding process includes crushers like jaw crushers or roller crushers for the initial breaking of the beans. For fine grinding, a ball mill or a high - speed grinder may be used. Filtration equipment such as filter presses or centrifuges are also important for separating the extract from solid residues.

How does the quality of kidney beans affect the grinding process?

The quality of kidney beans can significantly affect the grinding process. High - quality, clean, and dry kidney beans are easier to grind evenly. If the beans are of poor quality, for example, if they are moldy or have a high moisture content, it can lead to clogging of the grinding equipment, uneven grinding, and may also affect the quality of the final extract.

What are the key factors to control during the kidney bean extract grinding process?

Key factors to control during the kidney bean extract grinding process include the grinding time, which affects the particle size of the extract. The temperature during grinding also needs to be controlled as excessive heat can damage the active components in the extract. The speed of the grinding equipment and the pressure applied (if applicable) are also important factors to ensure a consistent and high - quality grinding result.

How can one ensure the safety of the kidney bean extract grinding process?

To ensure the safety of the kidney bean extract grinding process, proper safety procedures should be followed. This includes wearing appropriate personal protective equipment such as gloves and goggles. The grinding equipment should be regularly maintained and inspected to prevent malfunctions. Also, following good manufacturing practices to avoid cross - contamination with other substances and ensuring proper ventilation in the grinding area to prevent the build - up of dust.

Related literature

- Kidney Bean Extract: Production and Applications"

- "Advanced Grinding Techniques for Botanical Extracts"

- "The Science behind Kidney Bean Extract Processing"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Kidney Bean Extract

2025-01-02

-

Lycopene

2025-01-02

-

White mustard seed extract

2025-01-02

-

Phellodendron Extract

2025-01-02

-

Black Rice Extract

2025-01-02

-

Avocado Extract Powder

2025-01-02

-

Scutellaria Extract

2025-01-02

-

Panax Ginseng Leaf Extract

2025-01-02

-

Saponin Extract

2025-01-02

-

Angelica sinensis extract

2025-01-02