- 0086-571-85302990

- sales@greenskybio.com

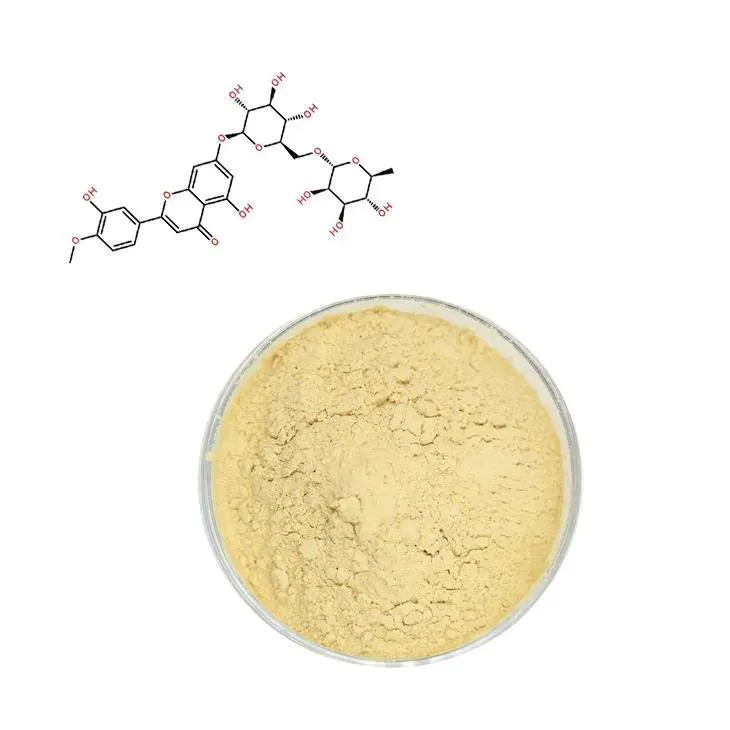

Diosmin products: Which extraction technologies should your enterprise invest in?

2024-12-21

1. Introduction

Diosmin, as an important substance, has been attracting increasing attention in the market. It has various applications in the fields of medicine, cosmetics, and food. With the growing demand for Diosmin, enterprises are constantly exploring more efficient and cost - effective extraction technologies. In this article, we will comprehensively analyze different extraction techniques for Diosmin, aiming to help enterprises make more informed decisions.

2. Solvent Extraction

2.1 Principle

Solvent extraction is a common method for diosmin extraction. The principle is relatively straightforward. It is based on the solubility difference of diosmin between the sample matrix and the extraction solvent. Diosmin is transferred from the original matrix to the extraction solvent. For example, some organic solvents can dissolve diosmin effectively. Commonly used solvents include methanol, ethanol, and ethyl acetate.

2.2 Advantages

- High efficiency: In many cases, solvent extraction can achieve a relatively high extraction rate in a relatively short time. For example, when using an appropriate solvent and extraction conditions, a large amount of diosmin can be extracted from the raw material. - Wide applicability: It can be applied to different types of raw materials containing diosmin. Whether it is plant - based raw materials or synthetic precursors, solvent extraction can be attempted.

2.3 Disadvantages

- Potential impurity introduction: The solvents themselves may contain some impurities, which may be introduced into the final diosmin product. For example, some solvents may have trace amounts of heavy metals or other organic impurities. - Solvent recycling issues: Solvent extraction often requires a large amount of solvent. After extraction, the solvent needs to be recycled to reduce costs and environmental impact. However, solvent recycling is a complex process. It requires special equipment and techniques to ensure that the recycled solvent meets the requirements for reuse.3. Subcritical Water Extraction

3.1 Principle

Subcritical water extraction is an innovative method. Water under sub - critical conditions (temperature and pressure between the normal boiling point and critical point of water) is used as the extraction solvent. Under these conditions, the physical and chemical properties of water, such as polarity and dielectric constant, change. This makes water have different solubility for diosmin compared to normal water. Diosmin can be effectively extracted from the raw material.

3.2 Advantages

- Environmental friendliness: Compared with some traditional organic solvents, subcritical water is more environmentally friendly. It does not produce organic solvent waste, reducing the environmental pollution risk. - Good selectivity: By adjusting the temperature and pressure parameters, the selectivity of subcritical water extraction for diosmin can be improved. It can selectively extract diosmin from complex matrices while reducing the extraction of other unwanted substances.

3.3 Disadvantages

- Requires precise control: The extraction process of subcritical water extraction highly depends on the precise control of temperature and pressure. A slight deviation in these parameters may lead to a significant change in the extraction efficiency and quality. Special equipment with high - precision control is required, which increases the cost of the extraction process. - Limited by raw material characteristics: Some raw materials may not be suitable for subcritical water extraction. For example, if the raw material has a high content of substances that are easily decomposed under sub - critical water conditions, it may affect the extraction of diosmin and the quality of the final product.4. Enzyme - Assisted Extraction

4.1 Principle

Enzyme - assisted extraction utilizes specific enzymes to break down the cell walls or matrices of the raw material, making diosmin more accessible for extraction. Enzymes can specifically act on certain components in the raw material, such as cellulose or pectin in plant cells. By hydrolyzing these components, the release of diosmin is facilitated.

4.2 Advantages

- Enhanced extraction yield: Enzymes can significantly increase the extraction yield of diosmin. They can break down the barriers that prevent diosmin from being released, resulting in more diosmin being extracted from the same amount of raw material. - Improved selectivity: Different enzymes can be selected according to the characteristics of the raw material and the target product. This can improve the selectivity of the extraction process, ensuring that mainly diosmin is extracted while minimizing the extraction of other substances.

4.3 Disadvantages

- Enzyme stability: Enzymes are proteins, and their stability is affected by various factors such as temperature, pH, and the presence of inhibitors. Maintaining the activity of enzymes during the extraction process is a challenge. If the enzyme loses its activity, the extraction efficiency will be greatly reduced. - Cost: The production and use of enzymes involve certain costs. High - quality enzymes are often expensive, and the cost of enzyme - assisted extraction may be relatively high compared to other methods. In addition, the cost of enzyme recovery and reuse also needs to be considered.5. Comparison and Selection

When an enterprise decides which extraction technology to invest in for diosmin production, it needs to comprehensively consider various factors.

5.1 Cost - Benefit Analysis

- For solvent extraction, although the initial equipment investment may be relatively low, the cost of solvents and solvent recycling should be considered in the long run. If the enterprise has a large - scale production plan, the cost of solvent procurement and waste treatment may be significant. - Subcritical water extraction requires high - precision control equipment, which means a relatively high initial investment. However, considering its environmental friendliness and potential for high - quality product production, in the long - term, it may bring economic benefits through reducing environmental costs and improving product quality. - Enzyme - assisted extraction has high enzyme costs. But if the increase in extraction yield and product quality can offset these costs, it may also be a viable option.

5.2 Product Quality Requirements

- If the enterprise has high requirements for product purity and impurity control, subcritical water extraction and enzyme - assisted extraction may have certain advantages. Subcritical water extraction can reduce impurity introduction due to the use of water as a solvent, and enzyme - assisted extraction can improve selectivity. - Solvent extraction may face challenges in impurity control, but if appropriate purification steps are added, it can also meet certain quality requirements.

5.3 Production Scale

- For small - scale production, solvent extraction may be more flexible due to its relatively simple equipment and operation. - For medium - to - large - scale production, subcritical water extraction and enzyme - assisted extraction may be more suitable considering long - term development and cost - effectiveness. Subcritical water extraction can better meet environmental requirements at a large scale, and enzyme - assisted extraction can improve production efficiency at a large scale.6. Conclusion

Each extraction technology for diosmin has its own characteristics, advantages, and disadvantages. Enterprises need to make a comprehensive assessment based on their own actual situation, including cost - benefit, product quality requirements, and production scale. By in - depth analysis of these technologies, enterprises can find the most suitable extraction technology for their diosmin production, which is crucial for the long - term development and competitiveness of the enterprise in the diosmin market.

FAQ:

What are the main extraction technologies for diosmin?

There are mainly three extraction technologies for diosmin. The first one is solvent extraction. It is relatively simple in principle but may introduce impurities and has solvent recycling problems. The second is subcritical water extraction. It uses water under sub - critical conditions, which is more environmentally friendly but requires precise control of temperature and pressure. The third is enzyme - assisted extraction. It can increase the extraction yield and selectivity, while enzyme stability and cost need to be considered.

What are the limitations of solvent extraction for diosmin?

The limitations of solvent extraction for diosmin mainly include potential impurity introduction and solvent recycling issues. These problems may affect the purity of the final product and also bring environmental and cost - related challenges.

Why is subcritical water extraction considered more environmentally friendly?

Subcritical water extraction is considered more environmentally friendly because it uses water under sub - critical conditions instead of some traditional solvents. Traditional solvents may be harmful to the environment, while water is a more natural and less polluting medium.

What factors should be considered when using enzyme - assisted extraction?

When using enzyme - assisted extraction, two main factors should be considered. One is enzyme stability. Unstable enzymes may not perform well during the extraction process. The other is cost. Enzymes can be expensive, and the cost needs to be balanced with the benefits of increased yield and selectivity.

How can enterprises choose the most suitable extraction technology for diosmin production?

Enterprises can choose the most suitable extraction technology for diosmin production by in - depth analysis of the features, advantages, and disadvantages of different technologies. They need to consider factors such as product purity, environmental impact, cost, and production efficiency of each technology.

Related literature

- Advances in Diosmin Extraction: A Review"

- "Comparative Study of Different Diosmin Extraction Methods"

- "The Future of Diosmin Extraction Technologies in the Industry"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Buckthorn bark extract

2024-12-21

-

Saw Palmetto Extract

2024-12-21

-

Mango flavored powder

2024-12-21

-

Sea buckthorn oil

2024-12-21

-

Black Rice Extract

2024-12-21

-

Andrographis Paniculata Extract Powder

2024-12-21

-

Agaricus Blazei Extract

2024-12-21

-

Acerola Extract

2024-12-21

-

Genistein

2024-12-21

-

Eucommia Ulmoides Extract

2024-12-21