- 0086-571-85302990

- sales@greenskybio.com

Eucommia ulmoides Extract Production: A Complete Guide for Consumers and Manufacturers

2024-12-22

1. Introduction

Eucommia ulmoides, also known as "Du - Zhong" in Chinese, has been highly valued in traditional medicine for its numerous health benefits. The production of Eucommia Ulmoides Extract is a complex process that involves multiple steps from the selection of raw materials to the final packaging of the product. This guide aims to provide a comprehensive understanding for both consumers and producers.

2. Raw Materials

2.1. Source of Eucommia ulmoides

Eucommia ulmoides is mainly native to China. It is typically grown in certain regions with suitable climate and soil conditions. Producers should ensure that the raw materials are sourced from reliable suppliers who follow sustainable cultivation practices. This not only guarantees the quality of the raw materials but also helps in the long - term conservation of this valuable plant species.

2.2. Selection Criteria

When selecting Eucommia ulmoides for extract production, several factors need to be considered. Firstly, the age of the plant matters. Generally, older plants tend to have a higher concentration of active compounds. Secondly, the health of the plant is crucial. Plants free from diseases and pests are preferred. Consumers should also be aware of these factors when choosing products, as they can indirectly affect the efficacy of the extract.

3. Harvesting

3.1. Timing

The timing of harvesting Eucommia ulmoides is critical. It is usually best to harvest during the appropriate season when the active compounds in the plant are at their peak levels. For Eucommia ulmoides, this is often in the autumn. Harvesting at the wrong time may result in a lower yield of active ingredients in the extract.

3.2. Methods

Proper harvesting methods should be employed to ensure the quality of the raw materials. Harvesters should be careful not to damage the plant during the process. Traditional harvesting tools such as pruning shears can be used. After harvesting, the plant parts should be quickly transported to the processing facility to prevent degradation of the active compounds.

4. Pretreatment

4.1. Cleaning

Once the Eucommia ulmoides is harvested, the first step in pretreatment is cleaning. The plant parts need to be thoroughly washed to remove dirt, debris, and any potential contaminants. This can be done using clean water and appropriate cleaning equipment. Any damaged or diseased parts should also be removed during this process.

4.2. Drying

After cleaning, drying is an essential step. Drying helps to reduce the moisture content of the plant materials, which is necessary for further processing. There are different drying methods available, such as natural drying in the sun or using drying machines. However, care should be taken to ensure that the drying temperature and time are properly controlled to avoid over - drying or under - drying, which can affect the quality of the extract.

5. Extraction

5.1. Solvent Selection

The choice of solvent for extraction is crucial. Different solvents can extract different types of active compounds from Eucommia ulmoides. Commonly used solvents include ethanol, water, and sometimes a combination of both. Ethanol - based extracts are often used for their ability to extract a wide range of lipophilic and hydrophilic compounds. However, when producing extracts for consumer use, the solvent residue must be carefully controlled to meet safety standards.

5.2. Extraction Methods

There are several extraction methods available, such as maceration, percolation, and ultrasonic - assisted extraction. Maceration involves soaking the dried Eucommia ulmoides in the solvent for a certain period of time. Percolation is a continuous extraction method where the solvent is passed through the plant material. Ultrasonic - assisted extraction uses ultrasonic waves to enhance the extraction efficiency. Producers need to choose the most appropriate extraction method based on factors such as cost, efficiency, and the desired quality of the extract.

6. Purification

6.1. Filtration

After extraction, the extract usually contains impurities such as plant debris and undissolved particles. Filtration is a common purification method used to remove these impurities. There are different types of filters available, such as filter papers, membrane filters, and filter cartridges. The choice of filter depends on the size of the impurities and the desired purity of the extract.

6.2. Concentration

Concentration is another important step in purification. The extract may be too dilute after extraction, and concentration is required to increase the concentration of active compounds. This can be achieved through methods such as evaporation under reduced pressure or reverse osmosis. However, during the concentration process, care should be taken to avoid over - concentration, which may lead to the degradation of active compounds.

7. Quality Control

7.1. Chemical Analysis

Quality control in Eucommia Ulmoides Extract production involves chemical analysis. This includes the determination of the content of active compounds such as aucubin, geniposidic acid, and other bioactive substances. High - performance liquid chromatography (HPLC) and gas chromatography (GC) are commonly used analytical techniques. Producers must ensure that the extract meets the specified quality standards in terms of active compound content.

7.2. Microbiological Testing

Microbiological testing is also essential. The extract should be free from harmful microorganisms such as bacteria, fungi, and molds. Tests such as total plate count, yeast and mold count, and pathogen detection should be carried out. If the extract fails the microbiological testing, it cannot be used for consumer products.

8. Packaging

8.1. Packaging Materials

The choice of packaging materials is important for the preservation of Eucommia Ulmoides Extract. Packaging materials should be able to protect the extract from factors such as light, moisture, and oxygen. Dark - colored glass bottles or aluminum - laminated pouches are often used for their good barrier properties. Additionally, the packaging should be labeled clearly with information such as product name, ingredients, usage instructions, and expiration date.

8.2. Storage Conditions

Proper storage conditions are necessary to maintain the quality of the extract. Eucommia ulmoides extract should be stored in a cool, dry place, away from direct sunlight. The ideal storage temperature is usually between 2 - 8 °C. Consumers should follow these storage instructions to ensure the efficacy of the product they purchase.

9. Benefits and Applications

9.1. Health Benefits

Eucommia ulmoides extract has been associated with several health benefits. It is believed to have anti - inflammatory properties, which can help in reducing inflammation in the body. It may also have a positive effect on bone health, potentially improving bone density. Additionally, it has been studied for its potential in regulating blood pressure and improving cardiovascular health.

9.2. Applications in Cosmetics

In the cosmetics industry, Eucommia ulmoides extract is used in various products. It can be added to skin creams and lotions for its antioxidant properties, which can help in protecting the skin from free radical damage. It may also have moisturizing and anti - aging effects, making it a popular ingredient in anti - aging cosmetics.

9.3. Applications in Dietary Supplements

As a dietary supplement, Eucommia ulmoides extract is often sold in capsule or tablet form. It is consumed by those who are interested in maintaining overall health, improving joint function, or enhancing physical performance. However, it is important for consumers to follow the recommended dosage and consult a healthcare professional before starting to take any dietary supplements.

10. Conclusion

The production of Eucommia ulmoides extract is a multi - step process that requires careful attention at each stage, from raw material selection to final packaging. For producers, strict quality control measures are necessary to ensure the production of high - quality extracts. For consumers, understanding the production process can help them make more informed decisions when choosing Eucommia ulmoides - based products.

FAQ:

Q1: What are the main raw materials for Eucommia ulmoides extract production?

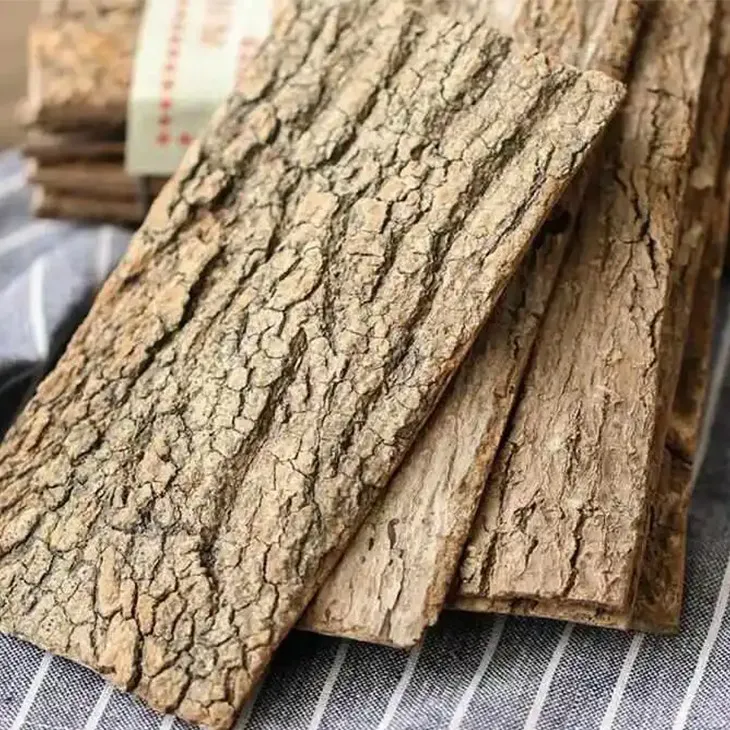

The main raw material for Eucommia ulmoides extract production is, of course, Eucommia ulmoides. This plant is rich in various bioactive components. Usually, different parts of the Eucommia ulmoides plant, such as the bark, leaves, etc., can be used as raw materials, depending on the specific requirements of the extract.

Q2: How is the quality of Eucommia ulmoides raw materials ensured?

To ensure the quality of Eucommia ulmoides raw materials, several factors need to be considered. Firstly, the source of the plant is crucial. It should be sourced from reliable regions with suitable growth conditions. Secondly, proper harvesting techniques are required. Harvesting at the appropriate time can ensure the optimal content of active ingredients. Thirdly, strict quality inspection procedures are carried out, including tests for purity, absence of contaminants, and the content of key bioactive substances.

Q3: What are the common extraction methods for Eucommia ulmoides extract?

Common extraction methods for Eucommia ulmoides extract include solvent extraction and supercritical fluid extraction. Solvent extraction uses solvents such as ethanol to dissolve and extract the active ingredients from the raw materials. Supercritical fluid extraction, often using carbon dioxide as the supercritical fluid, has the advantages of being more environmentally friendly and capable of obtaining a purer extract with better quality control.

Q4: How can consumers identify high - quality Eucommia ulmoides extract products?

Consumers can identify high - quality Eucommia ulmoides extract products in several ways. Firstly, look at the product label. A reliable product should clearly state the extraction method, the content of key ingredients, and the source of the raw materials. Secondly, check for certifications and quality marks. Thirdly, research the reputation of the manufacturer. A well - known and reputable manufacturer is more likely to produce high - quality products. Additionally, the appearance and smell of the extract can also provide some clues. High - quality extracts usually have a characteristic odor and a relatively pure appearance.

Q5: What are the potential health benefits of Eucommia ulmoides extract?

Eucommia ulmoides extract is believed to have several potential health benefits. It may have anti - inflammatory properties, which can help reduce inflammation in the body. It is also thought to have antioxidant effects, protecting cells from oxidative damage. Some studies suggest that it may help in improving bone health, perhaps due to its potential to enhance calcium absorption. Additionally, it may have a positive impact on blood pressure regulation and cardiovascular health, although more research is needed to fully confirm these effects.

Related literature

- The Bioactive Components of Eucommia ulmoides and Their Health - Promoting Effects"

- "Eucommia ulmoides: From Traditional Medicine to Modern Extract Production"

- "Quality Control in Eucommia ulmoides Extract Manufacturing"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Bitter Melon Extract

2024-12-22

-

Bamboo Leaf extract

2024-12-22

-

Saffron Extract Powder

2024-12-22

-

Sea buckthorn Juice Powder

2024-12-22

-

Black Pepper Extract

2024-12-22

-

Kelp Extract Powder

2024-12-22

-

Dan Shen Root Extract/Salvia Root Extract

2024-12-22

-

Feverfew Extract

2024-12-22

-

Polygonum multiflorum extract

2024-12-22

-

Ivy Extract

2024-12-22