- 0086-571-85302990

- sales@greenskybio.com

Four Main Methods for Extracting Astaxanthin from Plants.

2024-12-15

1. Introduction

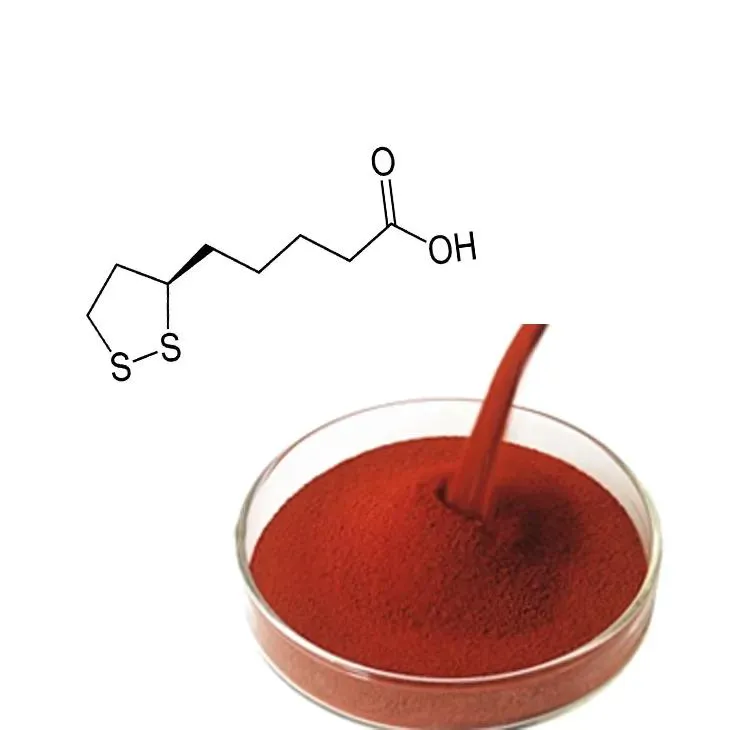

Astaxanthin is a powerful antioxidant with numerous potential health benefits. It is found in certain plants and has gained significant attention in various industries, including the food, pharmaceutical, and cosmetic sectors. Extracting Astaxanthin from plants is crucial to make it available for these applications. There are four main methods for this extraction, each with its own characteristics and advantages. This article will explore these methods in detail.

2. Solvent Extraction

2.1 General Principle

Solvent extraction is one of the most commonly used methods for extracting Astaxanthin from plants. The principle behind this method is based on the solubility of astaxanthin in certain solvents. The plant material containing astaxanthin is mixed with an appropriate solvent, which can dissolve the astaxanthin. Then, through processes such as filtration and evaporation, the astaxanthin can be separated from the solvent and obtained in a relatively pure form.

2.2 Commonly Used Solvents

There are several solvents that are often used in solvent extraction. For example, hexane is a non - polar solvent that can effectively dissolve non - polar compounds like astaxanthin. Another solvent is ethyl acetate, which has a certain polarity and can also be used for extraction. However, different solvents may have different extraction efficiencies and selectivities.

2.3 Advantages

One of the main advantages of solvent extraction is its relatively simple operation. It does not require highly specialized equipment and can be carried out in a normal laboratory or industrial setting. Also, the extraction efficiency can be relatively high under appropriate conditions. For example, if the right solvent and extraction parameters are chosen, a significant amount of astaxanthin can be extracted from the plant material.

2.4 Disadvantages

However, solvent extraction also has some drawbacks. The most significant one is the solvent - related issues. Firstly, solvents may be toxic, such as some halogenated solvents. Their use requires strict safety precautions to protect the operators and the environment. Secondly, the solvent residues in the final product may pose a threat to human health if not completely removed. This requires additional purification steps, which can increase the cost and complexity of the extraction process.

3. Supercritical Fluid Extraction

3.1 General Principle

Supercritical fluid extraction is a relatively advanced extraction method. Supercritical fluids are substances that are at a temperature and pressure above their critical points. For example, carbon dioxide can be used as a supercritical fluid in the extraction of astaxanthin. At supercritical conditions, carbon dioxide has unique properties such as high diffusivity and low viscosity, which enable it to penetrate into the plant material effectively and dissolve astaxanthin.

3.2 Advantages

One of the most notable advantages of supercritical fluid extraction is its environmental - friendly nature. Since carbon dioxide is often used as the supercritical fluid, it is non - toxic, non - flammable, and has a relatively low environmental impact. Moreover, the extraction quality is high. The supercritical fluid can selectively extract astaxanthin, leaving behind many impurities in the plant material. This results in a relatively pure astaxanthin product. Additionally, the extraction process can be controlled more precisely by adjusting parameters such as temperature and pressure.

3.3 Disadvantages

Despite its advantages, supercritical fluid extraction also has some limitations. The equipment required for this method is relatively expensive. High - pressure systems are needed to maintain the supercritical state of the fluid, which requires a large initial investment. Also, the operation process is more complex compared to solvent extraction. Skilled operators are required to ensure the proper operation of the equipment and the stability of the extraction process.

4. Enzymatic Extraction

4.1 General Principle

Enzymatic extraction is based on the use of enzymes to break down the plant cell structures. Plants contain cell walls that can act as barriers to the extraction of astaxanthin. Enzymes can specifically target certain components of the cell walls, such as cellulose and pectin, and hydrolyze them. This breaks down the cell walls and makes the astaxanthin inside the cells more accessible to extraction.

4.2 Advantages

An important advantage of enzymatic extraction is that it can improve the extraction yield. By gently breaking down the cell structures, more astaxanthin can be released from the plant cells. Moreover, enzymatic extraction is generally considered to be a milder method compared to solvent extraction. It can preserve the integrity of astaxanthin to a greater extent, as there is no harsh chemical treatment involved. This can be beneficial for applications where the quality of astaxanthin is crucial, such as in the pharmaceutical industry.

4.3 Disadvantages

However, enzymatic extraction also has some challenges. Enzymes are relatively expensive, which can increase the cost of the extraction process. Also, the enzymatic reaction needs to be carefully controlled. Factors such as enzyme concentration, reaction time, and temperature need to be optimized to achieve the best extraction results. If these parameters are not properly controlled, the extraction efficiency may be affected.

5. Microwave - Assisted Extraction

5.1 General Principle

Microwave - assisted extraction utilizes microwave technology to enhance the extraction process. Microwaves can cause the plant material to heat up rapidly and unevenly. This generates internal pressure differences within the plant cells, which can lead to the rupture of cell walls. As a result, astaxanthin can be more easily released from the cells and dissolved in the extraction solvent.

5.2 Advantages

The most significant advantage of microwave - assisted extraction is that it can significantly enhance the extraction efficiency. Compared to traditional extraction methods, microwave - assisted extraction can reduce the extraction time. For example, in some cases, the extraction time can be reduced from several hours to just a few minutes. This not only saves time but also reduces energy consumption. Additionally, the method can also improve the quality of the extracted astaxanthin in some cases, as the short extraction time may reduce the degradation of astaxanthin.

5.3 Disadvantages

On the other hand, microwave - assisted extraction also has some limitations. The equipment used for microwave - assisted extraction needs to be carefully designed to ensure uniform heating. Uneven heating can lead to incomplete extraction or degradation of astaxanthin. Also, the scale - up of this method from laboratory to industrial production may face some challenges. For example, larger - scale microwave equipment may be more complex and expensive to operate.

6. Comparison and Selection of Methods

6.1 Comparison

When comparing these four methods, solvent extraction is simple but has solvent - related problems. Supercritical fluid extraction is environmentally friendly and has high extraction quality but is expensive. Enzymatic extraction can improve yield gently but is costly and requires careful control. Microwave - assisted extraction is efficient but has challenges in scale - up and ensuring uniform heating.

6.2 Selection

The selection of the extraction method depends on various factors. For small - scale or laboratory - scale extraction, enzymatic or microwave - assisted extraction may be more suitable due to their relatively fast extraction times and potentially high yields. For large - scale industrial production, supercritical fluid extraction may be preferred if cost is not the primary concern, considering its environmental - friendliness and high - quality product. Solvent extraction may still be used in some cases where simplicity and cost - effectiveness are more important, despite its solvent - related issues.

7. Conclusion

In conclusion, the four methods of extracting astaxanthin from plants, namely solvent extraction, supercritical fluid extraction, enzymatic extraction, and microwave - assisted extraction, each have their own features. They play important roles in different scenarios of astaxanthin extraction. Future research may focus on improving these methods further, for example, reducing the cost of supercritical fluid extraction equipment, optimizing the enzymatic reaction in enzymatic extraction, and improving the scale - up of microwave - assisted extraction. With continuous development, these methods will contribute more effectively to the extraction and utilization of astaxanthin from plants.

FAQ:

What are the advantages of supercritical fluid extraction in astaxanthin extraction?

Supercritical fluid extraction is noted for its environmental - friendly nature. It does not leave behind harmful solvent residues as in some traditional solvent extraction methods. Also, it can achieve high extraction quality, which means it can effectively extract astaxanthin with high purity and good quality from plants.

How does enzymatic extraction improve the yield of astaxanthin extraction?

Enzymatic extraction improves the extraction yield by gently breaking down plant cell structures. The enzymes target the cell walls of the plants, which contain astaxanthin. By breaking down these cell walls, the astaxanthin, which was previously trapped inside the cells, can be more easily released and thus the overall extraction yield is increased.

What are the potential solvent - related issues in solvent extraction of astaxanthin?

Some potential solvent - related issues in solvent extraction include the presence of solvent residues in the final product. These residues can be harmful if consumed and may also require additional purification steps to remove them. Moreover, some solvents may be flammable or toxic, posing safety risks during the extraction process.

How does microwave - assisted extraction enhance the efficiency of astaxanthin extraction?

Microwave - assisted extraction uses microwave technology. Microwaves can heat the plant material and the solvent (if used) very quickly and evenly. This rapid heating causes the cells in the plant material to rupture more easily, releasing astaxanthin faster and more efficiently compared to traditional extraction methods that do not use microwaves.

Which method is the most cost - effective for astaxanthin extraction from plants?

The cost - effectiveness of each method depends on various factors. Solvent extraction may be relatively inexpensive in terms of equipment and reagents, but it may incur additional costs for solvent removal and purification. Supercritical fluid extraction requires specialized equipment which is costly, but it may be more cost - effective in the long run due to high - quality extraction. Enzymatic extraction requires the purchase of enzymes which can be expensive, and microwave - assisted extraction also requires microwave - specific equipment. In general, if large - scale production with lower quality requirements is considered, solvent extraction may be more cost - effective, but for high - quality astaxanthin extraction, supercritical fluid extraction may be a better choice despite the high initial investment.

Related literature

- Astaxanthin: Sources, Extraction, Stability, Biological Activities and Its Commercial Applications"

- "Recent Advances in Astaxanthin Production and Extraction from Microalgae"

- "Extraction of Astaxanthin from Natural Sources: A Review"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Chia Seed Powder

2024-12-15

-

Selenium yeast

2024-12-15

-

Propolis Extract Powder

2024-12-15

-

Yohimbine Bark Extract

2024-12-15

-

Acerola Juice Powder

2024-12-15

-

Tormentil Extract

2024-12-15

-

Apricot Powder

2024-12-15

-

Pomegranate Extract

2024-12-15

-

Lily extract

2024-12-15

-

Bamboo Leaf extract

2024-12-15