- 0086-571-85302990

- sales@greenskybio.com

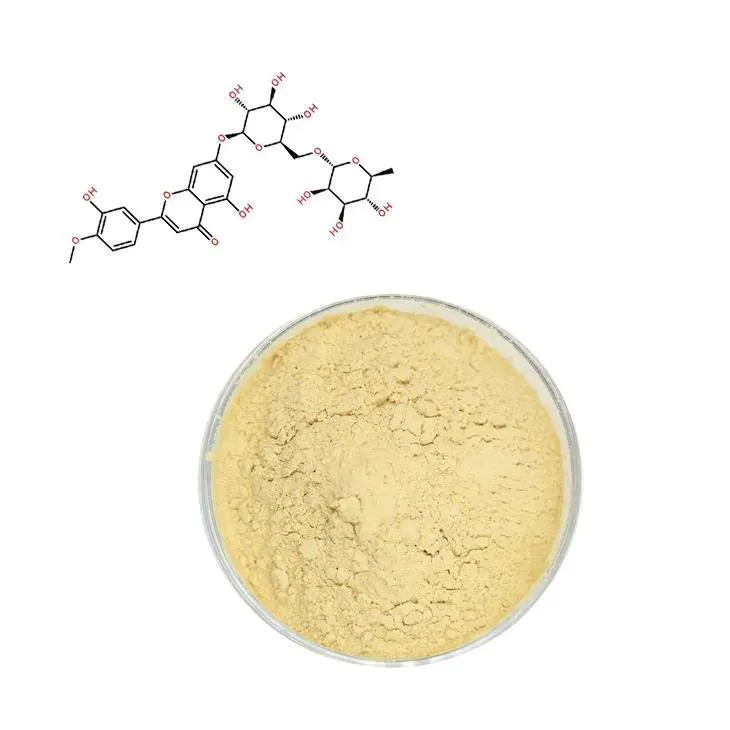

Four Main Methods for Extracting Diosmin from Plants.

2024-12-30

1. Introduction

Diosmin, a flavonoid compound, has been widely recognized for its numerous pharmacological properties. It is commonly found in various plants. Extraction of Diosmin from plants is a crucial step in obtaining this valuable compound for use in pharmaceuticals, nutraceuticals, and cosmetics. In this article, we will explore four main methods for extracting Diosmin from plants, which will provide a comprehensive understanding of the production process of diosmin - based products.

2. Solvent Extraction

2.1 Principle

Solvent extraction is based on the principle of solubility. Diosmin has different solubilities in different solvents. Commonly used solvents include methanol, ethanol, and acetone. These solvents can dissolve diosmin from plant materials, separating it from other components in the plant.2.2 Procedure

- First, the plant material is dried and ground into a fine powder. This increases the surface area of the plant material, allowing for better solvent penetration.

- The powdered plant material is then placed in a Soxhlet extractor or a simple extraction flask. The solvent is added, and the extraction is carried out at a specific temperature for a certain period of time. For example, when using ethanol as a solvent, the extraction may be carried out at a temperature around 60 - 80°C for 2 - 4 hours.

- After extraction, the solvent containing diosmin is separated from the plant residue by filtration or centrifugation.

- The solvent is then evaporated, usually under reduced pressure, to obtain a crude extract of diosmin.

2.3 Advantages and Disadvantages

-

Advantages:

- It is a relatively simple and commonly used method. Many laboratories and industries are familiar with this technique.

- High extraction efficiency can be achieved if the appropriate solvent and extraction conditions are selected.

-

Disadvantages:

- The use of organic solvents may pose environmental and safety risks. Some solvents are flammable and toxic.

- The resulting crude extract may contain other impurities, requiring further purification steps.

3. Supercritical Fluid Extraction (SFE)

3.1 Principle

Supercritical fluid extraction utilizes the properties of supercritical fluids. A supercritical fluid has the characteristics of both a liquid and a gas. Carbon dioxide (CO₂) is the most commonly used supercritical fluid for diosmin extraction. In the supercritical state, CO₂ has a high diffusivity and low viscosity, which enables it to penetrate plant materials effectively and dissolve diosmin.3.2 Procedure

- The plant material is prepared in a similar way as in solvent extraction, by drying and grinding it into a powder.

- The powdered plant material is placed in an extraction vessel. CO₂ is pressurized and heated to reach its supercritical state. The supercritical CO₂ is then passed through the plant material.

- The dissolved diosmin in the supercritical CO₂ is separated from the plant residue. This can be achieved by changing the pressure and temperature conditions, causing the diosmin to precipitate out or be collected in a separate chamber.

3.3 Advantages and Disadvantages

-

Advantages:

- It is a "green" extraction method as CO₂ is non - toxic, non - flammable, and environmentally friendly. There are no solvent residues in the final product.

- The extraction selectivity can be adjusted by changing the pressure and temperature conditions, which can lead to a relatively pure diosmin extract.

-

Disadvantages:

- The equipment for supercritical fluid extraction is relatively expensive, requiring high - pressure systems and precise temperature and pressure control.

- The extraction process may be more complex compared to solvent extraction, and requires more technical expertise.

4. Microwave - Assisted Extraction (MAE)

4.1 Principle

Microwave - assisted extraction is based on the interaction between microwaves and plant materials. Microwaves can cause the polar molecules in plant cells, such as water molecules, to vibrate rapidly. This internal heating effect can break the cell walls of plants more effectively, facilitating the release of diosmin into the extraction solvent.4.2 Procedure

- The plant material is mixed with the extraction solvent in a microwave - safe container. The solvent can be the same as those used in solvent extraction, such as ethanol or methanol.

- The container is placed in a microwave oven, and the extraction is carried out at a specific microwave power and time. For example, an extraction may be carried out at a microwave power of 300 - 600 W for 5 - 15 minutes.

- After extraction, the mixture is cooled and filtered to separate the solvent containing diosmin from the plant residue.

4.3 Advantages and Disadvantages

-

Advantages:

- The extraction time is significantly shorter compared to traditional solvent extraction methods. This can increase the extraction efficiency and save time.

- The microwave - assisted extraction can be more energy - efficient, as it directly heats the plant - solvent mixture, reducing the overall energy consumption.

-

Disadvantages:

- The extraction process may be less uniform, especially when dealing with large - scale extraction. There may be hot spots in the microwave - irradiated area, which can lead to local over - extraction or under - extraction.

- The equipment may require special maintenance, and the microwave power and time need to be carefully optimized to ensure the best extraction results.

5. Ultrasound - Assisted Extraction (UAE)

5.1 Principle

Ultrasound - assisted extraction is based on the cavitation effect of ultrasound. When ultrasound is applied to the extraction system, it creates tiny bubbles in the solvent. These bubbles grow and then collapse violently, creating high - pressure and high - temperature micro - environments. This cavitation effect can disrupt the cell walls of plants, allowing the solvent to better penetrate and extract diosmin.5.2 Procedure

- The plant material is immersed in the extraction solvent in an ultrasonic bath or ultrasonic probe - equipped vessel.

- The ultrasound is applied at a specific frequency and power for a certain period of time. For example, an extraction may be carried out at an ultrasonic frequency of 20 - 50 kHz and a power of 100 - 300 W for 10 - 30 minutes.

- After extraction, the solvent containing diosmin is separated from the plant residue by filtration or centrifugation.

5.3 Advantages and Disadvantages

-

Advantages:

- Similar to microwave - assisted extraction, the extraction time is relatively short, which can improve the extraction efficiency.

- The cavitation effect can be more evenly distributed compared to microwave - assisted extraction, resulting in more uniform extraction.

-

Disadvantages:

- The extraction efficiency may be affected by factors such as the ultrasonic frequency, power, and the nature of the plant material. Optimization of these parameters can be complex.

- The ultrasonic equipment may also require regular maintenance, and continuous operation at high power may reduce the lifespan of the equipment.

6. Comparison and Conclusion

Each of the four extraction methods has its own advantages and disadvantages. Solvent extraction is a traditional and relatively simple method, but it has environmental and impurity issues. Supercritical fluid extraction is a "green" method with high selectivity, but the equipment is expensive. Microwave - assisted extraction and ultrasound - assisted extraction are both time - saving methods, but they also have their own challenges in terms of uniformity and equipment maintenance. In the actual production of diosmin - based products, the choice of extraction method should be based on factors such as cost, environmental requirements, product purity, and production scale. Overall, continuous research and improvement of these extraction methods are necessary to meet the increasing demand for high - quality diosmin in various fields.

FAQ:

What are the four main methods for extracting diosmin from plants?

The article only mentions that there are four main methods but doesn't detail them. It could be methods like solvent extraction, supercritical fluid extraction, microwave - assisted extraction, and enzymatic extraction, but this is just speculation without the full content of the article.

Why is it important to extract diosmin from plants?

Diosmin has important pharmacological properties. Extracting it from plants is crucial as it can be used in the production of various products with potential health benefits, such as in the treatment of certain circulatory disorders and as an antioxidant.

Are these extraction methods applicable to all plants containing diosmin?

Most likely not. Different plants may have different chemical compositions and physical structures. Some extraction methods may be more suitable for certain types of plants than others. For example, a plant with a high lipid content may respond better to a particular extraction method compared to a plant with a high cellulose content.

What are the advantages of each extraction method?

Since the specific methods are not detailed in the given information, generally speaking, solvent extraction can be relatively simple and cost - effective. Supercritical fluid extraction may offer better selectivity and less solvent residue. Microwave - assisted extraction can be faster. Enzymatic extraction may be more environmentally friendly. But these are just general advantages and would depend on the actual situation for each specific extraction of diosmin.

How can the purity of diosmin extracted from plants be ensured?

To ensure the purity of diosmin, multiple purification steps may be involved. This could include techniques such as chromatography (e.g., high - performance liquid chromatography), crystallization, and filtration. Additionally, proper control of the extraction conditions, such as temperature, pressure, and solvent concentration, can also contribute to obtaining a purer product.

Related literature

- “Diosmin: A Review of Its Pharmacological Properties and Therapeutic Applications”

- “Plant - Based Extraction Techniques: A Comprehensive Guide”

- “Optimization of Diosmin Extraction from Medicinal Plants”

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Peppermint Oil

2024-12-30

-

Nettle leaf extract

2024-12-30

-

Berberis aristata Extract

2024-12-30

-

Yellow Pine Extract

2024-12-30

-

Lily extract

2024-12-30

-

Chasteberry Extract

2024-12-30

-

Epimedium extract powder

2024-12-30

-

Mangosteen extract powder

2024-12-30

-

Wheat Germ Extract

2024-12-30

-

Nutmeg Extract

2024-12-30