- 0086-571-85302990

- sales@greenskybio.com

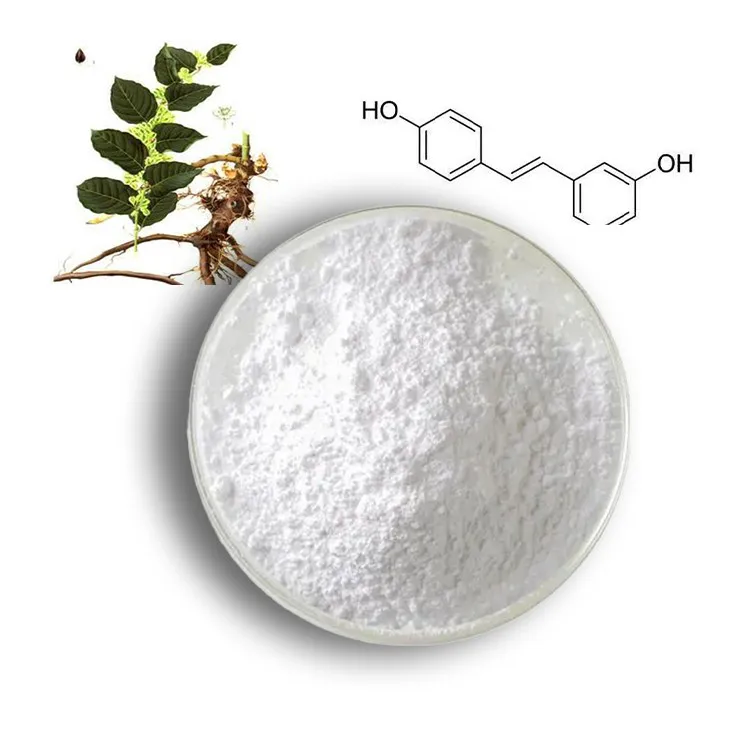

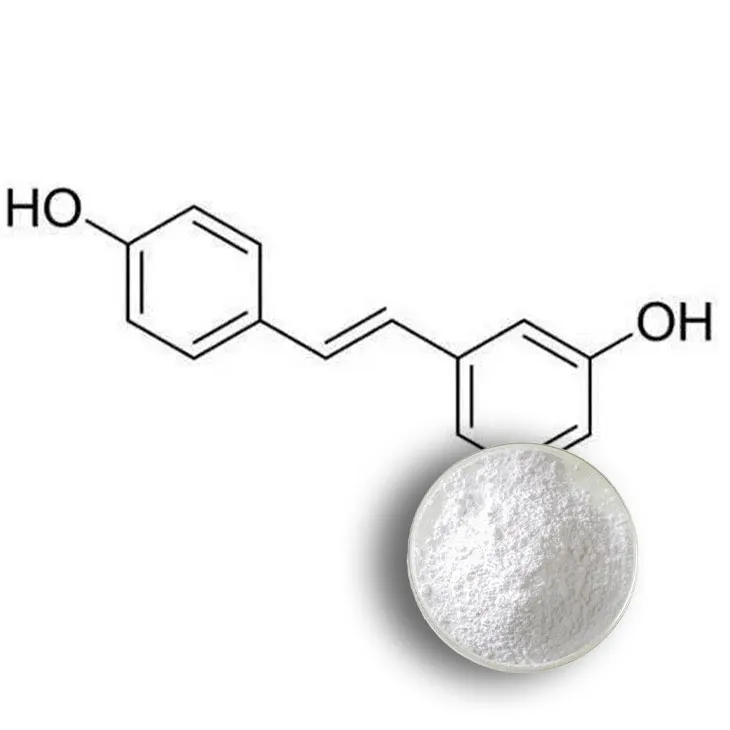

Four Main Methods for Extracting Resveratrol Extract from Plants.

2024-12-16

1. Introduction

Resveratrol is a natural phenolic compound that has attracted significant attention in recent years due to its numerous potential health benefits. It is found in various plants, such as grapes, peanuts, and berries. The extraction of resveratrol from plants is crucial for its application in the pharmaceutical, food, and cosmetic industries. In this article, we will discuss four main methods for extracting Resveratrol extract from plants.

2. Solvent Extraction

2.1 Principle

Solvent extraction is one of the most common methods for extracting resveratrol. The principle behind this method is based on the solubility of resveratrol in different solvents. Resveratrol is more soluble in organic solvents such as ethanol, methanol, and ethyl acetate. The plant material is soaked in the solvent, and the resveratrol is dissolved into the solvent. After that, the solvent containing resveratrol is separated from the plant residue through filtration or centrifugation.

2.2 Procedure

- First, the plant material is dried and ground into a fine powder. This step is important as it increases the surface area of the plant material, which in turn enhances the extraction efficiency.

- The powdered plant material is then added to the selected solvent. The ratio of plant material to solvent depends on the type of plant and the concentration of resveratrol expected. Usually, a ratio of 1:10 to 1:20 (plant material: solvent) is used.

- The mixture is stirred or shaken for a certain period of time. This time can range from a few hours to several days depending on the nature of the plant material and the solvent used. For example, for grape skins, a shaking time of 2 - 3 days at room temperature may be sufficient when using ethanol as the solvent.

- After the extraction period, the mixture is filtered to separate the liquid phase (containing resveratrol) from the solid plant residue. Filtration can be done using filter paper, a Buchner funnel, or a membrane filter depending on the scale of the extraction.

- The solvent is then evaporated under reduced pressure to obtain the Resveratrol extract. This can be done using a rotary evaporator. Care should be taken during this step to avoid overheating, which may cause degradation of resveratrol.

2.3 Advantages and Disadvantages

Advantages:

- It is a relatively simple and straightforward method that can be easily carried out in a laboratory or on an industrial scale.

- High extraction efficiency can be achieved with the right choice of solvent and extraction conditions.

- It allows for the extraction of a wide range of plant materials.

Disadvantages:

- The use of organic solvents may pose environmental and safety concerns. Some solvents are flammable, toxic, or volatile.

- The extraction process may also extract other compounds along with resveratrol, which may require further purification steps.

3. Supercritical Fluid Extraction (SFE)

3.1 Principle

Supercritical fluid extraction uses a supercritical fluid as the extraction solvent. A supercritical fluid is a substance that is above its critical temperature and critical pressure. For example, carbon dioxide (CO₂) is commonly used as a supercritical fluid in Resveratrol extraction. In the supercritical state, CO₂ has properties between those of a gas and a liquid. It has a high diffusivity like a gas, which allows it to penetrate into the plant material easily, and a high density like a liquid, which enables it to dissolve resveratrol effectively.

3.2 Procedure

- The plant material is first prepared by drying and grinding it into a fine powder, similar to the solvent extraction method.

- The powdered plant material is placed in an extraction vessel. CO₂ is then pressurized and heated above its critical point (critical temperature of 31.1 °C and critical pressure of 73.8 bar) to form a supercritical fluid.

- The supercritical CO₂ is passed through the plant material in the extraction vessel. The resveratrol is dissolved into the supercritical CO₂.

- The CO₂ - resveratrol mixture is then passed through a separator. By reducing the pressure and/or changing the temperature, the CO₂ returns to its gaseous state, leaving the resveratrol extract behind.

3.3 Advantages and Disadvantages

Advantages:

- Supercritical CO₂ is non - toxic, non - flammable, and environmentally friendly, which overcomes the safety and environmental concerns associated with organic solvents in solvent extraction.

- It provides a high - purity extract as it selectively extracts resveratrol and other target compounds while leaving behind many unwanted substances.

- The extraction process is relatively fast and can be easily controlled by adjusting the pressure, temperature, and flow rate of the supercritical fluid.

Disadvantages:

- The equipment required for supercritical fluid extraction is relatively expensive, which may limit its application on a small - scale or in some research laboratories.

- The extraction capacity may be lower compared to solvent extraction for some plant materials, especially those with a low resveratrol content.

4. Microwave - Assisted Extraction (MAE)

4.1 Principle

Microwave - assisted extraction utilizes microwave energy to enhance the extraction process. Microwaves can heat the plant material and the solvent simultaneously. The heating is caused by the interaction of microwaves with the polar molecules in the plant material and the solvent. This rapid heating causes the cell walls of the plant material to rupture more easily, releasing the resveratrol into the solvent. The solvent can then dissolve the resveratrol more efficiently.

4.2 Procedure

- The plant material is dried and ground, and then placed in a microwave - compatible extraction vessel along with the selected solvent. The solvent can be ethanol, methanol, or other suitable solvents.

- The extraction vessel is placed in a microwave oven. The microwave power, extraction time, and solvent to plant material ratio are optimized according to the type of plant and the desired extraction efficiency. For example, a microwave power of 300 - 600 W and an extraction time of 5 - 15 minutes may be suitable for some plant materials.

- After the microwave - assisted extraction, the mixture is filtered to separate the liquid extract containing resveratrol from the plant residue.

- The solvent is evaporated to obtain the resveratrol extract, similar to the solvent extraction method.

4.3 Advantages and Disadvantages

Advantages:

- It significantly reduces the extraction time compared to traditional solvent extraction methods. The rapid heating by microwaves shortens the extraction process from hours or days to minutes.

- The extraction efficiency is relatively high as the microwaves can effectively break down the cell walls of the plant material, facilitating the release of resveratrol.

- It is a relatively energy - efficient method as it requires less energy compared to some other extraction methods.

Disadvantages:

- The extraction may not be uniform if the microwave energy is not evenly distributed in the extraction vessel, which may lead to inconsistent extraction results.

- The method may be more suitable for small - scale extractions as the scale - up may be challenging due to issues such as microwave penetration depth and uniformity of heating in larger volumes.

5. Ultrasonic - Assisted Extraction (UAE)

5.1 Principle

Ultrasonic - assisted extraction uses ultrasonic waves to enhance the extraction process. Ultrasonic waves create cavitation bubbles in the solvent. When these bubbles collapse, they generate high - pressure and high - temperature micro - environments. These micro - environments can cause mechanical and physical effects on the plant material, such as cell wall disruption and mass transfer enhancement. As a result, the resveratrol in the plant material can be more easily released into the solvent.

5.2 Procedure

- The plant material is dried and ground, and then placed in an extraction vessel with the solvent. The solvent selection is similar to other extraction methods, such as ethanol or methanol.

- An ultrasonic probe or ultrasonic bath is used to generate ultrasonic waves in the extraction vessel. The ultrasonic power, frequency, and extraction time are optimized according to the plant material and the desired extraction efficiency. For example, an ultrasonic power of 100 - 300 W, a frequency of 20 - 50 kHz, and an extraction time of 10 - 30 minutes may be used.

- After the ultrasonic - assisted extraction, the mixture is filtered to obtain the liquid extract containing resveratrol, and the solvent is evaporated to get the final resveratrol extract.

5.3 Advantages and Disadvantages

Advantages:

- It is a relatively simple and inexpensive method as the equipment required for ultrasonic - assisted extraction is relatively affordable compared to some other extraction methods, such as supercritical fluid extraction.

- The extraction efficiency is enhanced as the ultrasonic waves can effectively disrupt the cell walls of the plant material, promoting the release of resveratrol.

- It can be used for a wide variety of plant materials and solvents.

Disadvantages:

- The ultrasonic waves may cause some degradation of resveratrol or other compounds in the plant material if the extraction conditions are not properly controlled.

- Similar to microwave - assisted extraction, the scale - up may be difficult as the uniformity of the ultrasonic field may be affected in larger - scale extractions.

6. Conclusion

In conclusion, the four main methods for extracting resveratrol extract from plants - solvent extraction, supercritical fluid extraction, microwave - assisted extraction, and ultrasonic - assisted extraction - each have their own advantages and disadvantages. The choice of extraction method depends on various factors such as the type of plant material, the desired purity of the resveratrol extract, the scale of extraction (laboratory or industrial), cost - effectiveness, and environmental and safety considerations. Future research may focus on improving these extraction methods, developing hybrid methods that combine the advantages of different techniques, or finding new plant sources with higher resveratrol content for more efficient extraction.

FAQ:

What are the four main methods for extracting resveratrol extract from plants?

The four main methods include solvent extraction, supercritical fluid extraction, ultrasonic - assisted extraction, and microwave - assisted extraction. Each method has its own characteristics and advantages in terms of extraction efficiency, cost, and quality of the resveratrol extract obtained.

Which method is the most cost - effective for extracting resveratrol extract?

Solvent extraction is often considered relatively cost - effective. It uses common solvents like ethanol or methanol. However, it may have some limitations in terms of purity compared to other methods. Supercritical fluid extraction can produce high - purity resveratrol but is generally more expensive due to the need for specialized equipment and high - pressure operation. The choice of the most cost - effective method also depends on factors such as the scale of production and the quality requirements of the end - product.

How does ultrasonic - assisted extraction work in extracting resveratrol?

Ultrasonic - assisted extraction uses ultrasonic waves. These waves create cavitation bubbles in the solvent - plant material mixture. When these bubbles collapse, they generate intense local forces and high - temperature and - pressure micro - environments. This helps to break the cell walls of the plants more effectively, allowing the resveratrol to be released into the solvent more efficiently compared to traditional extraction methods without ultrasonic assistance.

What are the advantages of supercritical fluid extraction for resveratrol?

Supercritical fluid extraction offers several advantages. It can operate at relatively low temperatures, which is beneficial for heat - sensitive compounds like resveratrol, reducing the risk of degradation. It can also achieve high selectivity, resulting in a relatively pure resveratrol extract. Additionally, the supercritical fluid (usually carbon dioxide) is non - toxic, non - flammable, and can be easily removed from the extract, leaving behind a relatively clean product.

How does microwave - assisted extraction contribute to resveratrol extraction?

Microwave - assisted extraction uses microwaves to heat the solvent - plant material system. The microwaves cause the polar molecules in the solvent and plant cells to rotate rapidly, generating heat. This heat helps to disrupt the cell structure and enhance the mass transfer of resveratrol from the plant cells into the solvent. It can significantly reduce the extraction time compared to traditional extraction methods.

Related literature

- Resveratrol Extraction from Plants: A Comprehensive Review of Methods and Applications"

- "Advances in Resveratrol Extraction Technologies: Solvent - based and Non - solvent - based Approaches"

- "Comparative Study of Different Extraction Methods for Resveratrol from Plant Sources"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Dan Shen Root Extract/Salvia Root Extract

2024-12-16

-

Maitake Mushroom Extract

2024-12-16

-

Kelp Extract Powder

2024-12-16

-

Grapefruit Seed Extract Powder

2024-12-16

-

Troxerutin

2024-12-16

-

Maca Extract

2024-12-16

-

Pueraria Lobata Extract

2024-12-16

-

Coix Seed Extract

2024-12-16

-

Elderberry Extract

2024-12-16

-

Hawthorn Extract

2024-12-16