- 0086-571-85302990

- sales@greenskybio.com

How can astaxanthin manufacturers wholesale and customize products?

2024-12-19

1. Introduction

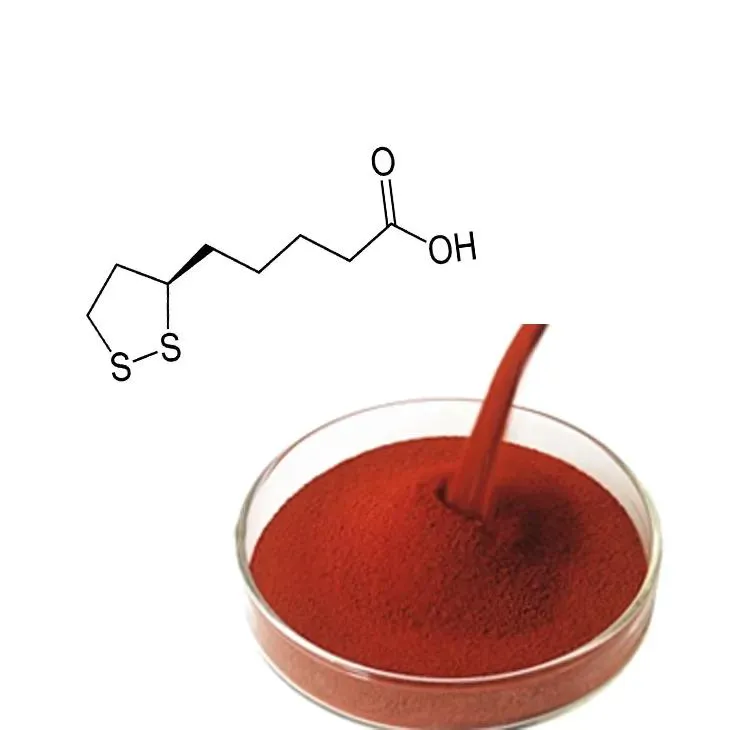

In the highly competitive Astaxanthin manufacturing industry, manufacturers are constantly seeking ways to gain an edge. Wholesale and custom - made product strategies are two crucial aspects that can significantly impact their success. Astaxanthin, with its diverse applications in nutraceuticals, cosmetics, and aquaculture, among others, presents both opportunities and challenges for manufacturers. This article delves into the details of how Astaxanthin manufacturers can effectively manage wholesale and custom - made product activities.

2. Wholesale Strategies

2.1 Market Segmentation

Market segmentation is the foundation of successful wholesale in the astaxanthin industry. Manufacturers need to identify and target specific customer segments.

- In the nutraceutical industry, consumers are increasingly aware of the health benefits of astaxanthin, such as its antioxidant properties. Manufacturers can target health - conscious consumers, fitness enthusiasts, and those looking for natural supplements. For example, they can develop wholesale packages specifically for supplement retailers, offering different dosages and forms (e.g., capsules, tablets) to meet the diverse needs of this segment.

- The cosmetic industry is another significant market segment. Astaxanthin's antioxidant and skin - enhancing properties make it a valuable ingredient in skincare products. Manufacturers can collaborate with cosmetic brands, providing astaxanthin in quantities suitable for large - scale production of creams, serums, and lotions. They can also offer customized formulations for different skin types, such as anti - aging products for mature skin or products for sensitive skin.

- For the aquaculture industry, astaxanthin is widely used as a feed additive to enhance the color of fish and shellfish. Manufacturers should understand the specific requirements of aquaculture farms, such as the type of species they raise (e.g., salmon, shrimp), the scale of production, and the regulatory compliance in different regions. By segmenting the market in this way, they can develop targeted wholesale offers, including bulk quantities of astaxanthin with appropriate packaging for easy handling in aquaculture facilities.

2.2 Product Positioning

Once the market segments are identified, product positioning becomes crucial.

- Quality positioning: Astaxanthin manufacturers must emphasize the high quality of their products. This includes factors such as purity, source (e.g., natural vs. synthetic), and production methods. For example, manufacturers of natural astaxanthin can position their products as superior in the market, highlighting the benefits of natural extraction methods over synthetic ones. They can provide certificates of analysis to prove the purity and quality of their astaxanthin, which is especially important for the nutraceutical and cosmetic industries where consumers are more sensitive to product quality.

- Price positioning: Pricing strategy should be based on the cost structure, competition, and perceived value of the product. In the wholesale market, manufacturers can offer different price tiers. For instance, they can have a basic price for large - volume orders from cost - sensitive customers in the aquaculture industry, while setting a higher price for smaller, high - value - added custom - formulated products for the cosmetic industry. However, it is essential to ensure that the price - quality relationship is maintained to build long - term customer relationships.

- Function - based positioning: Depending on the target market segment, manufacturers can position their astaxanthin products based on their functions. In the nutraceutical industry, they can focus on the health benefits like antioxidant support, joint health, and eye health. In the cosmetic industry, the positioning can be centered around skin - brightening, anti - aging, and anti - inflammatory properties. For the aquaculture industry, the function of enhancing the color and improving the overall health of the aquatic organisms can be emphasized.

2.3 After - Sales Service

After - sales service is often overlooked but is a vital part of the wholesale business for astaxanthin manufacturers.

- Technical support: Provide technical assistance to customers, especially those in the nutraceutical and aquaculture industries. For example, in the nutraceutical industry, manufacturers can offer guidance on the proper dosage and storage of astaxanthin products. In the aquaculture industry, they can assist customers with the correct use of astaxanthin as a feed additive, including advice on mixing ratios and feeding schedules.

- Product returns and exchanges: Have a clear and fair policy for product returns and exchanges. This is important as it builds customer trust. For instance, if a customer in the cosmetic industry receives a batch of astaxanthin that does not meet the specified quality standards, the manufacturer should be able to promptly address the issue through returns or exchanges.

- Customer feedback collection: Actively collect customer feedback to improve products and services. Manufacturers can use surveys, interviews, or online feedback forms to gather insights from customers in all market segments. For example, they can ask customers in the nutraceutical industry about their experience with the taste and effectiveness of astaxanthin supplements, and use this feedback to make improvements in future product formulations.

3. Custom - Made Product Strategies

3.1 In - Depth Communication with Clients

In - depth communication with clients is the key to creating successful custom - made astaxanthin solutions.

- Understanding client needs: Manufacturers need to have detailed discussions with clients to understand their specific requirements. For example, a cosmetic brand may require astaxanthin with a particular level of purity and a specific particle size for better incorporation into their products. By listening carefully to these needs, manufacturers can develop customized products that meet the exact specifications of the client.

- Sharing product knowledge: Manufacturers should also share their knowledge about astaxanthin with clients. This includes information about its properties, potential applications, and limitations. For instance, if a nutraceutical company is interested in developing a new product with astaxanthin, the manufacturer can educate them about the optimal dosage levels based on scientific research, as well as any potential interactions with other ingredients.

- Collaborative product development: Encourage collaborative product development with clients. In the aquaculture industry, for example, a fish farm may work with an astaxanthin manufacturer to develop a new feed formulation that not only enhances the color of the fish but also improves their growth rate and resistance to diseases. Through such collaboration, both parties can benefit from the shared expertise and resources.

3.2 Considerations in Custom - Made Product Creation

When creating custom - made astaxanthin products, several factors need to be considered.

- Raw material sourcing: The source of astaxanthin can significantly impact the quality and properties of the final product. For custom - made products, manufacturers need to ensure that they can source the right type of astaxanthin raw materials. For example, if a client in the high - end cosmetic industry requires natural astaxanthin from a specific source (e.g., microalgae), the manufacturer must have a reliable supply chain in place to meet this requirement.

- Production technology: Different custom - made products may require different production technologies. For instance, if a client in the nutraceutical industry wants astaxanthin in a specific delivery form (e.g., a time - release capsule), the manufacturer needs to have the appropriate production technology to create such a product. This may involve investing in new equipment or modifying existing production processes.

- Quality assurance: Quality assurance is crucial in custom - made product creation. Manufacturers must establish strict quality control procedures to ensure that each custom - made product meets the required standards. For example, in the production of custom - formulated astaxanthin for the aquaculture industry, the manufacturer needs to test the product for purity, stability, and effectiveness in enhancing the color and health of the aquatic organisms.

4. Factors Affecting Wholesale and Custom - Made Product Activities

4.1 Raw Material Sourcing

Raw material sourcing is a critical factor for both wholesale and custom - made product activities in the astaxanthin manufacturing industry.

- Source diversity: Manufacturers should consider diversifying their raw material sources. For example, they can source astaxanthin from both natural sources (such as microalgae and krill) and synthetic sources. This helps to ensure a stable supply of raw materials and can also provide flexibility in meeting different customer requirements. For wholesale customers in the nutraceutical industry, some may prefer natural astaxanthin, while others may be more cost - sensitive and open to synthetic options.

- Supplier relationships: Building strong relationships with suppliers is essential. A reliable supplier can provide consistent quality raw materials, on - time delivery, and may offer favorable pricing terms. For custom - made products, especially those with specific raw material requirements, a good supplier relationship can ensure that the manufacturer can obtain the necessary materials in a timely manner. For example, if a manufacturer has a long - term contract with a microalgae supplier for natural astaxanthin, they can better plan their production schedules and meet the custom - made product orders more efficiently.

- Cost of raw materials: The cost of raw materials directly impacts the profitability of wholesale and custom - made products. Manufacturers need to constantly monitor the market for raw materials and look for cost - effective sourcing options. However, they should not sacrifice quality for cost. In the case of custom - made products, they need to balance the cost of raw materials with the client's budget and the desired product quality. For instance, if a cosmetic brand has a high - end product line and is willing to pay a premium for top - quality astaxanthin, the manufacturer can source the best - quality raw materials accordingly.

4.2 Production Technology

Production technology plays a significant role in the production of astaxanthin for both wholesale and custom - made products.

- Innovation in production: Manufacturers should invest in innovative production technologies to improve product quality, increase production efficiency, and reduce costs. For example, new extraction methods for astaxanthin from natural sources can enhance the purity and yield of the product. In the wholesale market, this can give manufacturers a competitive advantage by offering higher - quality products at a lower cost. For custom - made products, innovative production technologies can enable the creation of unique products with specific properties. For instance, using advanced encapsulation techniques to create custom - designed astaxanthin capsules for the nutraceutical industry.

- Scalability of production: The production technology should be scalable to meet the varying demands of wholesale and custom - made product orders. In the wholesale market, manufacturers may receive large - volume orders from different industries. Their production technology should be able to handle these large - scale productions without sacrificing quality. For custom - made products, even though the order quantities may be smaller, the production technology should be flexible enough to produce different formulations and product forms. For example, a manufacturer may need to switch from producing a standard astaxanthin powder for wholesale to a custom - formulated astaxanthin - based cream for a cosmetic client.

- Technology transfer and training: Manufacturers need to ensure that their production staff is well - trained in the latest production technologies. In addition, they may need to consider technology transfer when collaborating with clients on custom - made products. For example, if a client in the aquaculture industry wants to use a new type of astaxanthin feed additive produced with a novel production technology, the manufacturer needs to train the client's staff on how to handle and use the product properly.

4.3 Quality Assurance

Quality assurance is of utmost importance in both wholesale and custom - made product activities for astaxanthin manufacturers.

- Quality control systems: Manufacturers should establish comprehensive quality control systems. This includes setting quality standards for raw materials, in - process products, and final products. For wholesale products, strict quality control ensures that all products meet the general market requirements. For custom - made products, the quality control system should be tailored to meet the specific quality requirements of each client. For example, a quality control system for a custom - made astaxanthin product for the cosmetic industry may include additional tests for skin - compatibility and stability in different cosmetic formulations.

- Certifications and compliance: Obtaining relevant certifications and complying with industry regulations is essential. In the astaxanthin manufacturing industry, certifications such as Good Manufacturing Practice (GMP) and ISO standards can enhance the credibility of the products. For wholesale products, these certifications can help manufacturers enter different international markets. For custom - made products, clients may also require specific certifications depending on their target markets. For example, a nutraceutical client may require that the astaxanthin product has organic certification if they are targeting the organic supplement market.

- Continuous improvement: Quality assurance is an ongoing process. Manufacturers should continuously monitor and improve their quality assurance processes. This can be achieved through regular internal audits, customer feedback analysis, and benchmarking against industry best practices. For both wholesale and custom - made products, continuous improvement in quality assurance can lead to increased customer satisfaction and loyalty.

5. Conclusion

In conclusion, for astaxanthin manufacturers to succeed in wholesale and custom - made product activities, they need to adopt a comprehensive approach. By effectively implementing strategies in market segmentation, product positioning, and after - sales service for wholesale, and engaging in in - depth communication with clients and considering various factors in custom - made product creation, while also taking into account raw material sourcing, production technology, and quality assurance, manufacturers can navigate the complex landscape of the astaxanthin industry. This will not only help them to stand out in the highly competitive market but also build long - term relationships with customers, ensuring their sustainable development in the industry.

FAQ:

Q1: What are the key factors in market segmentation for astaxanthin wholesale?

Market segmentation for astaxanthin wholesale involves considering different industries' needs. For the nutraceutical industry, customers may focus on its health - enhancing properties. In the cosmetic industry, they might be interested in its antioxidant effects for skin care. For the aquaculture industry, it is often used to improve the color and health of aquatic organisms. So, understanding these specific demands of different sectors is crucial.

Q2: How can astaxanthin manufacturers ensure product positioning in wholesale?

To ensure product positioning in wholesale, manufacturers should first analyze the unique selling points of their astaxanthin products. This could include factors like high purity, advanced production technology, or sustainable sourcing. Then, they need to match these features with the needs of the target customer segments. For example, if targeting high - end nutraceutical companies, emphasizing purity and quality certifications would be important.

Q3: What kind of after - sales service is important for astaxanthin wholesale?

After - sales service in astaxanthin wholesale can include providing technical support, such as helping customers with proper storage and usage instructions. Offering product quality guarantees and handling any complaints or returns promptly are also vital. Additionally, providing updated information about new research or applications related to astaxanthin can enhance customer satisfaction.

Q4: How can manufacturers communicate effectively with clients for custom - made astaxanthin products?

Manufacturers can start by actively listening to the clients' requirements. This includes understanding their specific end - use applications, desired product characteristics like concentration or formulation. Using clear and technical language to discuss options, providing samples if possible, and maintaining regular communication throughout the customization process are effective ways to communicate.

Q5: What role does raw material sourcing play in astaxanthin manufacturing for wholesale and custom - made products?

Raw material sourcing is crucial. High - quality raw materials can ensure the purity and effectiveness of astaxanthin products. For wholesale, consistent quality of raw materials helps maintain product uniformity. In custom - made products, the source of raw materials can be adjusted according to the specific requirements of clients, for example, using organic - sourced raw materials if the client targets the organic market.

Q6: How can production technology influence astaxanthin wholesale and custom - made products?

Advanced production technology can increase production efficiency and product quality. In wholesale, it can help reduce costs and meet large - scale production demands. For custom - made products, production technology allows for more flexibility in formulating different products. For example, it can enable the creation of different forms of astaxanthin, such as powders or capsules, according to client needs.

Related literature

- Astaxanthin: Production, Applications, and Market Trends"

- "The Role of Astaxanthin in Nutraceutical and Cosmetic Industries: A Comprehensive Review"

- "Astaxanthin in Aquaculture: Production and Quality Assurance"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Beetroot juice Powder

2024-12-19

-

Maitake Mushroom Extract

2024-12-19

-

Acerola Extract

2024-12-19

-

Calendula Extract

2024-12-19

-

Dandelion Root Extract

2024-12-19

-

American Ginseng Root Extract

2024-12-19

-

Elderberry Extract

2024-12-19

-

Alfalfa Meal

2024-12-19

-

Pueraria Lobata Extract

2024-12-19

-

Hedyotis Diffusa Extract

2024-12-19