- 0086-571-85302990

- sales@greenskybio.com

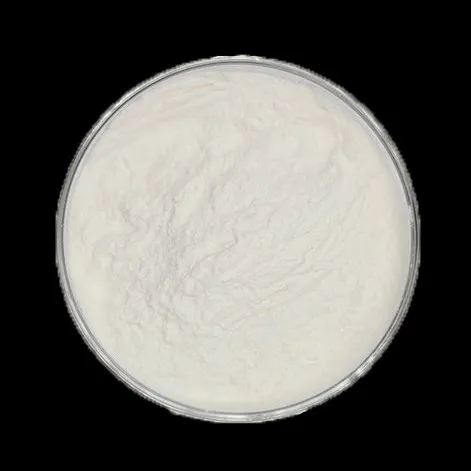

Only cooperate with the best contract manufacturers of Garcinia cambogia extract.

2024-12-16

Introduction

In the world of health and wellness products, Garcinia Cambogia Extract has gained significant popularity. As businesses look to capitalize on this trend, it is crucial that they only cooperate with the best contract manufacturers in this field. The quality of the extract, regulatory compliance, and innovation capabilities of the manufacturer can have a profound impact on the success of the final product in the market.

Quality Control in Garcinia Cambogia Extract Manufacturing

1. Raw Material Sourcing

- The best contract manufacturers begin with high - quality raw materials. For garcinia cambogia, this means sourcing from reliable suppliers. They ensure that the Garcinia cambogia fruits are of the appropriate species and are harvested at the right time. This is crucial as the quality of the raw material directly affects the potency and purity of the extract.

- Manufacturers also conduct strict inspections of incoming raw materials. They check for factors such as moisture content, presence of contaminants, and overall quality. Any sub - standard raw materials are rejected to prevent issues in the final product.

- State - of - - art manufacturing facilities are a hallmark of the best contract manufacturers. These facilities are equipped with advanced extraction technologies. For example, they may use supercritical CO2 extraction, which is known for producing high - quality, pure extracts while minimizing the use of solvents.

- Quality control checks are carried out at every stage of the manufacturing process. This includes monitoring the extraction parameters such as temperature, pressure, and extraction time. Any deviation from the optimal conditions can result in a lower - quality extract.

- After extraction, the Garcinia Cambogia Extract undergoes further purification and concentration processes. The manufacturers ensure that these processes are carried out accurately to maintain the integrity of the active compounds in the extract.

- Before the garcinia cambogia extract is released for use in products, comprehensive testing is done. This includes analysis of the active ingredient content, such as the amount of hydroxycitric acid (HCA), which is the main bioactive compound in garcinia cambogia.

- Tests for contaminants such as heavy metals, pesticides, and microbial contaminants are also mandatory. The best manufacturers ensure that their products meet strict safety and quality standards, both locally and internationally.

- Stability testing is another important aspect. This determines how the extract will fare over time under different storage conditions. A stable extract is essential for ensuring the efficacy of products that contain garcinia cambogia extract.

Regulatory Compliance in the Industry

1. Understanding Global Regulations

- The best contract manufacturers are well - versed in the regulatory requirements for garcinia cambogia extract in different countries. For example, in the United States, the Food and Drug Administration (FDA) has certain guidelines regarding the safety and labeling of dietary supplements containing garcinia cambogia extract.

- In the European Union, regulations are also in place to ensure the quality and safety of such products. Manufacturers need to comply with directives such as the Novel Food Regulation for new ingredients.

- They also keep track of regulatory changes in emerging markets. As the demand for garcinia cambogia - based products grows in countries like China and India, manufacturers must adapt to the local regulatory frameworks.

- Thorough documentation is a key part of regulatory compliance. Manufacturers must maintain records of the entire production process, from raw material sourcing to final product testing. This includes certificates of analysis for raw materials, batch production records, and quality control test results.

- These records are not only important for regulatory inspections but also for traceability. In case of any issues with the product, such as a quality complaint or a safety concern, the manufacturer can quickly trace back the production process to identify the root cause.

- GMP is a set of guidelines that ensure the consistent production of high - quality products. The best contract manufacturers strictly adhere to GMP standards. This includes aspects such as proper sanitation in the manufacturing facility, well - trained staff, and proper handling and storage of raw materials and finished products.

- By following GMP, manufacturers can reduce the risk of product contamination, ensure accurate dosing of the active ingredients, and maintain overall product quality.

Innovative Capabilities of the Best Manufacturers

1. Research and Development

- Leading contract manufacturers invest in research and development (R & D) related to garcinia cambogia extract. They explore new extraction methods to improve the efficiency and quality of the extract. For example, they may be researching ways to enhance the bioavailability of HCA, the active compound in garcinia cambogia.

- R & D efforts also focus on understanding the potential health benefits of garcinia cambogia in more depth. This could lead to the development of new products or formulations that target specific health conditions.

- The best manufacturers are not limited to just producing the basic garcinia cambogia extract. They are involved in product formulation innovation. This could involve creating combination products that pair garcinia cambogia extract with other complementary ingredients for enhanced efficacy.

- They also develop different forms of products, such as capsules, tablets, powders, and liquid extracts. Each form has its own advantages in terms of ease of use, absorption, and stability, and manufacturers need to optimize these factors.

- In the fast - paced health and wellness market, trends change quickly. The best contract manufacturers stay on top of these trends. For example, if there is a growing demand for natural and vegan - friendly products, they will develop garcinia cambogia - based products that meet these criteria.

- They also keep an eye on consumer preferences regarding taste, packaging, and convenience. By being responsive to market trends, they can help their partners stay competitive in the market.

Benefits of Partnering with the Best Manufacturers

1. High - Quality Products

- Partnering with top - tier contract manufacturers ensures that businesses get access to high - quality garcinia cambogia extract. This is essential for creating products that are effective and safe for consumers. High - quality products also help build a good brand reputation, which is crucial for long - term success in the market.

- In a highly competitive market, having a product made by a reputable manufacturer can give a business an edge. The best manufacturers often have advanced production capabilities and quality control measures that result in products that stand out from the competition.

- Their innovative product formulations and ability to keep up with market trends can also help businesses launch unique and appealing products, attracting more customers.

- When customers use products made with high - quality garcinia cambogia extract, they are more likely to be satisfied with the results. This leads to repeat purchases and positive word - of - mouth recommendations, which are invaluable for business growth.

Conclusion

In conclusion, when it comes to garcinia cambogia extract, businesses should only cooperate with the best contract manufacturers. The quality control, regulatory compliance, and innovative capabilities of these manufacturers are essential for creating successful products. By partnering with them, businesses can enjoy the benefits of high - quality products, increased market competitiveness, and greater customer satisfaction.

FAQ:

Question 1: What are the key factors to identify the best contract manufacturers of Garcinia cambogia extract?

The key factors include strict quality control measures. This means they have advanced testing facilities to ensure the purity, potency, and safety of the extract. Regulatory compliance is also crucial. The best manufacturers follow all relevant local and international regulations regarding production, labeling, and distribution. Innovation capabilities are another factor. They should be able to develop new extraction methods or improve existing ones to enhance the quality and effectiveness of the Garcinia cambogia extract.

Question 2: How can partnering with the best contract manufacturers improve product quality?

The best manufacturers have high - quality raw material sources. They use state - of - the - art extraction techniques which result in a more pure and effective Garcinia cambogia extract. Their quality control processes ensure that only products that meet strict standards are released. This leads to a final product with consistent quality, free from contaminants and with accurate potency, thereby improving the overall product quality.

Question 3: In what ways does partnering with top - tier contract manufacturers enhance market competitiveness?

Top - tier manufacturers can often produce high - quality products at a reasonable cost due to their efficient production processes. A high - quality Garcinia cambogia extract product can attract more customers and build a good reputation in the market. They may also have faster production times and the ability to scale up production easily, which gives a business an edge over competitors in terms of meeting market demands quickly.

Question 4: How does regulatory compliance by contract manufacturers contribute to customer satisfaction?

When contract manufacturers are compliant with regulations, it means that the products are produced, labeled, and distributed according to the set standards. This gives customers confidence in the product they are purchasing. Customers can be assured that the Garcinia cambogia extract they are using is safe, properly labeled with accurate information, and has passed all necessary quality checks, which ultimately leads to higher customer satisfaction.

Question 5: Can you give some examples of innovation capabilities in the best contract manufacturers of Garcinia cambogia extract?

Some manufacturers may have developed unique extraction techniques that preserve more of the active compounds in the Garcinia cambogia. For example, they might use a novel solvent - free extraction method that is both environmentally friendly and results in a higher - quality extract. Others may be innovating in the area of product formulation, such as creating new delivery systems for the extract to improve its bioavailability.

Related literature

- Quality Control in Garcinia cambogia Extract Production"

- "Regulatory Standards for Herbal Extract Manufacturers: A Focus on Garcinia cambogia"

- "Innovation in the Garcinia cambogia Extract Industry: Best Practices"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Soy Extract

2024-12-16

-

Andrographis Paniculata Extract Powder

2024-12-16

-

Buckthorn bark extract

2024-12-16

-

Selenium yeast

2024-12-16

-

Curcumin Extract

2024-12-16

-

Pueraria Lobata Extract

2024-12-16

-

Hericium erinaceus extract powder

2024-12-16

-

Hesperidin

2024-12-16

-

Lemon Juice Powder

2024-12-16

-

Giant Knotweed Extract

2024-12-16